Abstract

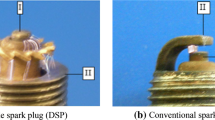

The ceramic insulators of spark plugs in gasoline engines are especially prone to damage when deto-knock occurs. To understand the damage process and mechanism, the present work investigated the impact resistance of ceramic insulators using detonation waves as impact sources. A test device that generates detonation waves was developed, representing a novel means of evaluating the knock resistance of ceramic insulators. Various impact types and detonation intensities were employed, and detonation initiation and propagation at peak pressures greater than 100 MPa were assessed using synchronous high-speed direct photography and pressure measurements. The test results demonstrate that ceramic insulators tend to break at the base of the breathing chamber when damaged by a single high peak pressure detonation wave impact. In contrast, multiple low pressure impacts eventually break the insulator into multiple fragments. The data also show that the positioning of a ground electrode upstream of the ceramic insulator greatly increases the resistance of the ceramic to the detonation impact. A two-dimensional computational fluid dynamics simulation coupled with a chemical kinetics analysis demonstrated that this improved resistance can be ascribed to a reduced peak pressure that appears after the detonation wave diffracts from the electrode prior to contacting the ceramic insulator.

Similar content being viewed by others

References

Wang, Z., Liu, H., Reitz, R.D.: Knocking combustion in spark-ignition engines. Prog. Energy Combust. Sci. 61, 78–112 (2017)

Fan, Q., Qi, Y., Wang, Z.: Investigation of effect of flame propagation and thermal conditions on the ultra-lean mixture ignition through a rapid compression machine. SAE Paper 2019-01-0963

Mayer, M., Hofmann, P., Williams, J., et al.: Influence of the engine oil on pre-ignitions at highly supercharged direct-injection gasoline engines. MTZ Worldw. 77(6), 36–41 (2016)

Passow, E.J., Sethi, P., Maschewske, M., et al.: An introduction to how low speed pre ignition affects engine components. SAE Paper 2017-03-28

Cavina, N., Rojo, N., Businaro, A., et al.: Analysis of pre-ignition combustions triggered by heavy knocking events in a turbocharged GDI engine. Energy Proc. 101, 893–900 (2016)

Worm, J.: The Impact of Water Injection on Spark Ignition Engine Performance Under High Load Operation. Michigan Technological University, Houghton (2017)

Walker, W.: Alumina insulators for high voltage automotive ignition systems. In: Singh, G., Bhalla, A., Mahmoud, M.M., et al. (eds.) Processing, Properties, and Design of Advanced Ceramics and Composites, pp. 359–370. Wiley, Hoboken (2016)

Qi, Y., Wang, Z., Wang, J., et al.: Effects of thermodynamic conditions on the end gas combustion mode associated with engine knock. Combust. Flame 162(11), 4119–4128 (2015)

PCB: PCM Model 119B11. http://www.pcb.com/products.aspx?m=119B11. Accessed Feb 10 2019

Lee, J.H.S.: The Detonation Phenomenon. Cambridge University Press, New York (2008)

Maly, R.R., Klein, R., Peters, N., et al.: Theoretical and experimental investigation of knock induced surface destruction. SAE Paper 900025 (1990)

Wang, Z., Liu, H., Song, T., et al.: Relationship between super-knock and pre-ignition. Int. J. Engine Res. 16(2), 166–180 (2014)

Smith, G.P., Golden, D.M., Frenklach, M., et al.: GRI Mech 3.0. http://www.me.berkeley.edu/gri_mech/. Accessed Feb 10 2019

Perevozchikova, J.A., Buntov, E.A., Zatsepin, A.F.: Elastic moduli of alumina nanoceramics. J. Phys Conf. Ser. 643, 012100 (2015)

Hibbeler, R.C.: Mechanics of Materials, 9th edn. Pearson Prentice Hall, Boston (2014)

Accuratus: Aluminum Oxide, Al2O3 Ceramic Properties. https://accuratus.com/alumox.html. Accessed Feb 10 2019

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant Nos. 91541206 and 51706121) and China Postdoctoral Science Foundation (Grant No. 2017T100076).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Qi, Y., Wang, B. & Wang, Z. Impact Resistance of Spark Plug’s Ceramic Insulator During Ultra-high-Pressure Combustion Under Deto-Knock Conditions. Automot. Innov. 2, 137–145 (2019). https://doi.org/10.1007/s42154-019-00058-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42154-019-00058-0