Abstract

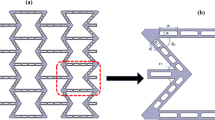

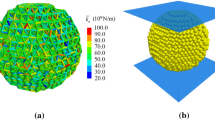

With the development of three-dimensional printing technologies, so-called cellular materials have achieved increasing attention due to outstanding properties. Unlike pure solid structures, properties of cellular materials are influenced by both utilized material and cell microtopology. The present paper proposes a novel type of re-entrant square cellular material. To explore the relationship between microtopology and macrodynamic responses systematically, an explicit dynamic finite element simulation method is used. This work starts by constructing theoretical models of relative density employing a two-dimensional unit cell. Then, the effects of geometric features and configurations on dynamic properties are explored, and simulations indicate that variations of geometric parameters strongly affect properties and that the staggered re-entrant squares are more stable than the regular re-entrant squares. Subsequently, the effects of the impact velocity on dynamic crushing behaviors are elaborated. On this basis, the relationship of unit mass energy absorption and geometric features is obtained by employing the response surface method. Furthermore, with targets of maximum unit mass energy absorption and minimum relative density, the optimal structural parameters are achieved by using non-dominated sorting genetic algorithm. The study provides a detailed introduction to dynamic behaviors of cellular materials and guidance to design new structures with superior characteristics of energy absorption.

Similar content being viewed by others

References

Schaedler, T.A., Carter, W.B.: Architected cellular materials. Ann. Rev. Mater. Res. 46(1), 187–210 (2016)

Zhang, Q., Yang, X., Li, P., et al.: Bioinspired engineering of honeycomb structure-using nature to inspire human innovation. Prog. Mater. Sci. 74, 332–400 (2015)

Dharmasena, K., Queheillalt, D., Wadley, H., et al.: Dynamic response of a multilayer prismatic structure to impulsive loads incident from water. Int. J. Impact Eng. 36(4), 632–643 (2009)

Xiong, J., Ma, L., Wu, L., et al.: Mechanical behavior of sandwich panels with hollow Al–Si tubes core construction. Mater. Des. 32(2), 592–597 (2011)

Liu, Y., Zhang, X.C.: The influence of cell micro-topology on the in-plane dynamic crushing of honeycombs. Int. J. Impact Eng. 36(1), 98–109 (2009)

Oftadeh, R., Haghpanah, B., Vella, D., et al.: Optimal fractal-like hierarchical honeycombs. Phys. Rev. Lett. 113(10), 104301 (2014)

Oftadeh, R., Haghpanah, B., Papadopoulos, J., et al.: Mechanics of anisotropic hierarchical honeycombs. Int. J. Mech. Sci. 81(4), 126–136 (2014)

Galehdari, S.A., Kadkhodayan, M., Hadidimoud, S.: Analytical, experimental and numerical study of a graded honeycomb structure under in-plane impact load with low velocity. Int. J. Crashworth. 20(4), 387–400 (2015)

Evans, A.G., Hutchinson, J.W., Ashby, M.F.: Multifunctionality of cellular metal systems. Prog. Mater. Sci. 43(3), 171–221 (1998)

Fleck, N.A., Deshpande, V.S.: The resistance of clamped sandwich beams to shock loading. J. Appl. Mech. 71(3), 386–401 (2004)

Hutchinson, J.W., Xue, Z.: Metal sandwich plates optimized for pressure impulse. Int. J. Mech. Sci. 47(4), 545–569 (2005)

Wang, A.J., Mcdowell, D.L.: In-plane stiffness and yield strength of periodic metal honeycombs. J. Eng. Mater. Technol. 126(2), 137–156 (2004)

Wang, A.J., Mcdowell, D.L.: Yield surfaces of various periodic metal honeycombs at intermediate relative density. Int. J. Plast. 21(2), 285–320 (2005)

Papka, S.D., Kyriakides, S.: Biaxial crushing of honeycombs: part 1: experiments. Int. J. Solids Struct. 36(29), 4367–4396 (1999)

Papka, S.D., Kyriakides, S.: In-plane biaxial crushing of honeycombs: part II: analysis. Int. J. Solids Struct. 36(29), 4397–4423 (1999)

Masters, I.G., Evans, K.E.: Models for the elastic deformation of honeycombs. Compos. Struct. 35(4), 403–422 (1996)

Smith, C.W., Grima, J.N., Evans, K.E.: A novel mechanism for generating auxetic behavior in reticulated foams: missing rib foam model. Acta Mater. 48(17), 4349–4356 (2000)

Liu, X.L., Chen, Y.W., Jing, X.R., et al.: Optimized latin hypercube sampling method and its application. J. Natl. Univ. Def. Technol. 33(5), 73–77 (2011)

Reyes, A., Hopperstad, O.S., Berstad, T., et al.: Constitutive modeling of aluminum foam including fracture and statistical variation of density. Eur. J. Mech. A. Solids 22(6), 815–835 (2003)

Kleijnen, J.P.C.: An overview of the design and analysis of simulation experiments for sensitivity analysis. Eur. J. Oper. Res. 164(2), 287–300 (2004)

Lopatnikov, S.L., Gama, B.A., Haque, M.J., et al.: High-velocity plate impact of metal foams. Int. J. Impact Eng. 30(4), 421–445 (2004)

Lopatnikov, S.L., Gama, B.A., Haque, M.J., et al.: Dynamics of metal foam deformation during Taylor cylinder-Hopkinson bar impact experiment. Compos. Struct. 61(1), 61–71 (2003)

Hönig, A., Stronge, W.J.: In-plane dynamic crushing of honeycomb. Part I: crush band initiation and wave trapping. Int. J. Mech. Sci. 44(8), 1665–1696 (2002)

Tan, P.J., Reid, S.R., Harrigan, J.J., et al.: Dynamic compressive strength properties of aluminum foams. Part II-‘shock’ theory and comparison with experimental data and numerical models. J. Mech. Phys. Solids 53(10), 2206–2230 (2005)

Yong, Z.: Design optimization on lightweight of full vehicle based on moving least square response surface method. J. Mech. Eng. 44(11), 192–196 (2008)

Holland, J.H.: Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, And Artificial Intelligence. University of Michigan Press, Ann Arbor (1975)

Acknowledgements

This work was supported by the China Scholarship Council (Grant No. 201606170199) and the National Key Research and Development Program of China (2016YFB0101601).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, F., Zhao, Y., Liang, H. et al. Effects of Cell Microtopology on the In-plane Dynamic Crushing Analysis of Re-entrant Square Cellular Material. Automot. Innov. 1, 24–34 (2018). https://doi.org/10.1007/s42154-018-0005-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42154-018-0005-0