Abstract

During composite fiber production, carbon fibers are normally derived from polyacrylonitrile precursor. Carbonization, as a key step of this process, is significantly energy-consuming and costly, owing to its high temperature requirement. A cost-effective approach to optimize energy consumption during the carbonization is implementing predictive modeling techniques. In this article, a Gaussian process approach has been developed to predict the mechanical properties of carbon fibers in the presence of manufacturing uncertainties. The model is also utilized to optimize the fiber mechanical properties under a minimum energy consumption criterion and a range of process constraints. Finally, as the Young’s modulus and ultimate tensile strength of the fibers did not show an evident correlation, a multi-objective optimization approach was introduced to acquire the overall optimum condition of the process parameters. To estimate the trade-off between these material properties, the standard as well as an adaptive weighted sum method were applied. Results were summarized as design chart for potential applications by manufacturing process designers.

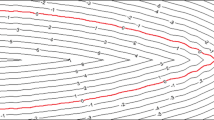

Graphical abstract

Similar content being viewed by others

References

Chand S (2000) Review carbon fibers for composites. J Mater Sci 35(6):1303–1313

Morgan P (2005) Carbon fibers and their composites. CRC press, Boca Raton

Park S-J (2015) Carbon Fibers. Springer, Dordrecht

Manocha LM, Bahl OP, Jain GC (1978) Length changes in PAN fibres during their pyrolysis to carbon fibres. Die Angewandte Makromolekulare Chemie: Applied Macromolecular Chemistry and Physics 67(1):11–29

Khayyam H, Naebe M, Zabihi O, Zamani R, Atkiss S, Fox B (2015) Dynamic prediction models and optimization of polyacrylonitrile (PAN) stabilization processes for production of carbon fiber. IEEE Transactions on Industrial Informatics 11(4):887–896

Titsias M (2009) Variational learning of inducing variables in sparse Gaussian processes. Artificial Intelligence and Statistics 12:567–574

Rasmussen CE (2004) Gaussian Processes in Machine Learning. In: Bousquet O, von Luxburg U, Rätsch G (eds) Advanced Lectures on Machine Learning. ML 2003. Lecture Notes in Computer Science, vol 3176. Springer, Berlin, Heidelberg, pp 63–71

Hensman J, Fusi N, Lawrence ND (2013) Gaussian processes for big data, arXiv preprint arXiv:1309.6835

Petelin D, Grancharova A, Kocijan J (2013) Evolving Gaussian process models for prediction of ozone concentration in the air. Simul Model Pract Theory 33:68–80

Gramacy RB, Haaland B (2016) Speeding up neighborhood search in local Gaussian process prediction. Technometrics 58(3):294–303

Corrado N, Gherlone M, Surace C, Hensman J, Durrande N (2015) Damage localisation in delaminated composite plates using a Gaussian process approach. Meccanica 50(10):2537–2546

Park SJ, Heo GY (2015) Precursors and manufacturing of carbon fibers. In: Carbon Fibers. Springer Series in Materials Science, vol 210. Springer, Dordrecht, pp 31–66

Peebles LH (1994) Carbon fibres: structure and mechanical properties. Int Mater Rev 39(2):75–92

Zhu D, Xu C, Nakura N, Matsuo M (2002) Study of carbon films from PAN/VGCF composites by gelation/crystallization from solution. Carbon 40(3):363–373

Khayyam H, Naebe M, Bab-Hadiashar A, Jamshidi F, Li Q, Atkiss S, Buckmaster D, Fox B (2015) Stochastic optimization models for energy management in carbonization process of carbon fiber production. Appl Energy 158:643–655

Ko T-H (1991) The influence of pyrolysis on physical properties and microstructure of modified PAN fibers during carbonization. J Appl Polym Sci 43(3):589–600

Mittal J, Mathur RB, Bahl OP (1997) Post spinning modification of PAN fibres—a review. Carbon 35(12):1713–1721

Yusof N, Ismail AF (2012) Post spinning and pyrolysis processes of polyacrylonitrile (PAN)-based carbon fiber and activated carbon fiber: a review. J Anal Appl Pyrolysis 93:1–13

Trinquecoste M, Carlier JL, Derré A, Delhaes P, Chadeyron P (1996) High temperature thermal and mechanical properties of high tensile carbon single filaments. Carbon 34(7):923–929

Khayyam H, Fakhrhoseini SM, Church JS, Milani AS, Bab-Hadiashar A, Jazar RN, Naebe M (2017) Predictive modelling and optimization of carbon fiber mechanical properties through high temperature furnace. Appl Therm Eng 125:1539–1554

Yuan J, Wang K, Yu T, Fang M (2008) Reliable multi-objective optimization of high-speed WEDM process based on Gaussian process regression. Int J Mach Tools Manuf 48(1):47–60

Quiñonero-Candela J, Rasmussen CE (2005) A unifying view of sparse approximate Gaussian process regression. J Mach Learn Res 6(Dec):1939–1959

Barber D (2012) Bayesian reasoning and machine learning. Cambridge University Press, Cambridge

Wilson A, Adams R (2013) Gaussian process kernels for pattern discovery and extrapolation. In: International Conference on Machine Learning (ICML), JMLR W&CP 28(3):1067–1075

Droste S, Jansen T, Wegener I (2002) A new framework for the valuation of algorithms for black-box-optimization. FOGA 3:253–270

Breusch TS, Pagan AR (1979) A simple test for heteroscedasticity and random coefficient variation. Econometrica: Journal of the Econometric Society 47:1287–1294

Engle RF (1982) Autoregressive conditional heteroscedasticity with estimates of the variance of United Kingdom inflation. Econometrica: Journal of the Econometric Society 50:987–1007

Tarpey T (2000) A note on the prediction sum of squares statistic for restricted least squares. Am Stat 54(2):116–118

Morgan JA, Tatar JF (1972) Calculation of the residual sum of squares for all possible regressions. Technometrics 14(2):317–325

Cameron AC, Windmeijer FA (1997) An R-squared measure of goodness of fit for some common nonlinear regression models. J Econ 77(2):329–342

Rardin RL, Rardin RL (1998) Optimization in operations research. Prentice Hall Upper Saddle River, NJ

Zadeh L (1963) Optimality and non-scalar-valued performance criteria. IEEE Trans Autom Control 8(1):59–60

Gass S, Saaty T (1955) The computational algorithm for the parametric objective function. Naval research logistics quarterly 2(1–2):39–45

Censor Y (1977) Pareto optimality in multiobjective problems. Appl Math Optim 4(1):41–59

Kim IY, de Weck OL (2005) Adaptive weighted-sum method for bi-objective optimization: Pareto front generation. Struct Multidiscip Optim 29(2):149–158

Das I, Dennis JE (1998) Normal-boundary intersection: a new method for generating the Pareto surface in nonlinear multicriteria optimization problems. SIAM J Optim 8(3):631–657

Kim IY, De Weck OL (2006) Adaptive weighted sum method for multiobjective optimization: a new method for Pareto front generation. Struct Multidiscip Optim 31(2):105–116

Acknowledgments

The support of colleagues and the stimulating discussions at the Composites Research Network and Carbon Nexus Institute are greatly valued.

Funding

This study was financially supported by the Natural Sciences and Engineering Research Council (NSERC) of Canada.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Raw experimental data obtained from carbonization process trials. For each set of process conditions, 50 trials have been performed [15]

Raw experimental data obtained from carbonization process trials. For each set of process conditions, 50 trials have been performed [15]

Temperature of zone 1 (°C) | Temperature of zone 2 (°C) | Time (s) | Modulus (GPa) | Modulus STD (GPa) | Tensile strength (GPa) | Tensile strength STD (GPa) | Energy consumption (kWh) |

|---|---|---|---|---|---|---|---|

1100 | 1400 | 156 | 228.8 | 18.47 | 3.016 | 1.06 | 11.87 |

1100 | 1400 | 167 | 227.7 | 9.288 | 3.201 | 0.68 | 11.95 |

1100 | 1400 | 162 | 227.5 | 9.89 | 3.275 | 0.77 | 11.92 |

1100 | 1400 | 151 | 234.6 | 13.67 | 3.458 | 0.76 | 11.86 |

1125 | 1425 | 156 | 228.3 | 14.48 | 2.925 | 1 | 12.19 |

1125 | 1425 | 167 | 229.2 | 34.03 | 3.185 | 0.81 | 12.44 |

1125 | 1425 | 162 | 226.7 | 11.66 | 3.031 | 0.81 | 12.4 |

1125 | 1425 | 151 | 231.9 | 15.9 | 3.225 | 0.59 | 12.37 |

1150 | 1450 | 156 | 219.8 | 7.797 | 2.945 | 0.63 | 12.49 |

1150 | 1450 | 167 | 221.8 | 10.11 | 3.13 | 0.87 | 12.58 |

1150 | 1450 | 162 | 217.6 | 32.99 | 3.11 | 0.65 | 12.51 |

1150 | 1450 | 151 | 224.3 | 10.78 | 3.18 | 0.63 | 12.47 |

1175 | 1475 | 156 | 197.7 | 35.32 | 2.78 | 0.68 | 12.7 |

1175 | 1475 | 167 | 154.2 | 9.5 | 2.11 | 0.36 | 12.81 |

1175 | 1475 | 162 | 157.5 | 9.13 | 2.35 | 0.41 | 12.77 |

1175 | 1475 | 151 | 163.02 | 5.39 | 2.209 | 0.34 | 12.65 |

Rights and permissions

About this article

Cite this article

Ramezankhani, M., Crawford, B., Khayyam, H. et al. A multi-objective Gaussian process approach for optimization and prediction of carbonization process in carbon fiber production under uncertainty. Adv Compos Hybrid Mater 2, 444–455 (2019). https://doi.org/10.1007/s42114-019-00107-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-019-00107-6