Abstract

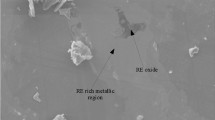

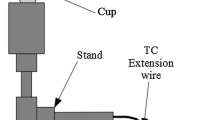

This paper discusses the thermal analysis of rare earth grain refined 4130. To accomplish this, heats of 4130 Baseline, 0.3 wt% RE silicide, and 0.3 wt% EGR were poured in a thermal analysis cup with a single S-type thermocouple at the bottom. A data acquisition system recorded the cooling curves whose values were compared to reference data. The samples were sectioned and macroetched. A scanning electron microscope analyzed the samples to determine inclusion composition. It was observed that the liquidus was similar for all the samples; however, the peritectic temperature for the 0.3 wt% RE and 0.3 wt% EGR was higher than the Baseline. This increase was thought to be due to RE oxysulfides acting as heterogeneous nuclei for austenite. A number of additional peaks appeared in the grain refined steels that seem to be related to the formation of RE oxysulfides during solidification. Macroetching found a larger equiaxed region in the TA cups from the treated steels and a finer structure. The improvement in microstructure seems related to the RE inclusions and peritectic temperature increase.

Similar content being viewed by others

References

G.K. Turnbull, D.M. Patton, G.W. Form, J.F. Wallace, Grain refinement of steel castings and weld deposits. Trans. Am. Foundrymen’s Soc. 69, 792–804 (1961)

G. Krauss, Steels: Processing, Structure, and Performance (ASM International, Materials Park, 2005)

G.K. Sigworth, T.A. Kuhn, Grain refinement of aluminum casting alloys. Int J Metalcast 1(1), 31–40 (2007)

J.E. Gruzleski, Microstructure Development During Metalcasting (American Foundrymen’s Society Inc, Schaumburg, 2000)

J. Speer, B. De Cooman, Fundamentals of Steel Product Physical Metallurgy (Association of Iron & Steel Technology, Pittsburg, 2011)

R.B. Tuttle, Effect of Rare Earth Additions on 4130. Proc. AISTech 2017, 3005–30015 (2017)

P.E. Waudby, Rare earth additions to steel. Int. Met. Rev. 23, 74–98 (1978)

F. Hao, B. Liao et al., Effects of rare earth oxide on hardfacing metal microstructure of medium carbon steel and its refinement mechanism. J. Rare Earths 29, 609–613 (2011)

R.B. Tuttle, Effect of RE oxide grain refinement on the heat treated properties of 1030 steel. Proc. AISTech 2014, 1619–1630 (2014)

R. Tuttle, Effect of rare earth oxides in plain carbon steels. Proc. AISTech 2013, 1085–1093 (2013)

R. Tuttle, J. Lewandowski, R. Tomazin, Effect of rare earth oxides on rolling performance on grain refined 1030. Proc. AISTech 2015, 3461–3471 (2015)

R. Tuttle, Effect of rare earth additions on grain refinement of plain carbon steels. Int. J. Metalcast. 6, 51–65 (2012)

J.J. Moore, Modification of the cast structure using rare earth additions, in Steelmaking Conference Proceedings, 67th (1984), pp. 239–254

M. Gajewski, J. Kasinska, Rare earth metals influence on mechanical properties and crack resistance of GP240GH and G17CrMo5-5 cast steels. Arch. Foundry Eng. 9, 37–44 (2009)

L. Wang, Q. Lin, L. Yue, L. Liu, F. Guo, F. Wang, Study of application of rare earth elements in advanced low alloy steels. J. Alloys Compd. 451, 534–537 (2008)

C. van der Eijk, J. Walmsley, Grain refinement of fully austenitic stainless steels using a Fe–Cr–Si–Ce master alloy, in 59th Electric Furnace and 19th Process Technology Conferences (2001), pp. 51–60

J. Kasinska, B. Kalandyk, Effects of rare earth metal addition on wear resistance of chromium–molybdenum cast steel. Arch. Foundry Eng. 17(3), 63–68 (2017)

M. Guo, H. Suito, Effect of dissolved cerium on austenite grain growth in an Fe–0.20mass%C–0.02mass%P alloy. ISIJ Int. 39, 1169–1175 (1999)

M. Guo, H. Suito, Influence of dissolved cerium and primary inclusion particles of Ce2O3 and CeS on solidification behavior of Fe–0.20 Mass%C–0.02 Mass%P alloy. ISIJ Int. 39, 722–729 (1999)

O. Grong, L. Kolbeinsen, C. van der Eijk, G. Tranell, Microstructure control of steels through dispersoid metallurgy using novel grain refining alloys. ISIJ Int. 46, 824–831 (2006)

R.B. Tuttle, Foundry Engineering: The Metallurgy and Design of Castings (CreateSpace Independent Publishing Platform, Charleston, 2012)

D.M. Stefanescu, Thermal analysis—theory and applications in metalcasting. Int. J. Metalcast. 9(1), 7–22 (2015)

J.G. Kaufman, E.L. Rooy, Aluminum Alloy Castings: Properties, Processes and Applications (ASM International, Materials Park, 2004)

AFS, Introduction to Gray Cast Iron Processing (American Foundry Society, Des Plaines, 2000)

Iron Castings Engineering Handbook (American Foundry Society, Des Plaines, 2003)

A. Bommareddy, R.B. Tuttle, Study of electrolytic dissolution in steels and rare earth oxide stability. Int. J. Metalcast. 10(2), 201–207 (2016)

Jernkontoret, A Guide to the Solidification of Steels (Jenkortoret, Stockholm, 1977)

E.A. Kelzer, Rapid carbon analysis. I. From liquidus arrest temperature. Metals 19, 50–52 (1967)

W.L. Kirker, Rapid carbon analysis. II. From open-hearth samples. Metals 19, 53–54 (1967)

E.B. Williams, Rapid carbon analysis. III. From thermal arrest temperature measurement. Metals 19, 55–56 (1967)

E. Wielgosz, T. Kargul, Differential scanning calorimetry study of peritectic steel grades. J. Therm. Anal. Calorim. 119(3), 1547–1553 (2015)

D.S. Likvidusnih, R.J. Metodami, D. Analize, Determination of the solidus and liquidus temperatures of the real-steel grades with dynamic thermal-analysis methods. Mater. Technol. 7, 569–575 (2013)

S.-H. Sun, A.-M. Zhao, R. Ding, X.-G. Li, Effect of heat treatment on microstructure and mechanical properties of quenching and partitioning steel. Acta Metall. Sin. (Engl. Lett.) 31(2), 216–224 (2018)

D. Fang, Q. Jun-mao, D. Hao-hua, Study on thermal physical properties of 304 stainless steel, in 6th International Symposium on High-Temperature Metallurgical Processing (2015), pp. 99–104

D. Arvola, R. O’Malley, S.N. Lekakh, L.N. Bartlett, Effect of phase solidification sequence in stainless steel on grain refining efficiency, in AISTech 2018 Proceedings, vol. III (2018), pp. 2651–2662

K.D. Carlson, C. Beckermann, Determination of solid fraction-temperature relation and latent heat using full scale casting experiments: application to corrosion resistant steels and nickel based alloys. Int. J. Cast Met. Res. 25, 75–92 (2012)

D.M. Stefanescu, Thermal analysis—theory and applications in metalcasting. Int. J. Metalcast. 9(1), 7–22 (2015)

J.-O. Andersson, T. Helander, L. Hoglund, P. Shi, B. Sundman, Thermo-Calc & DICTRA, computational tools for materials science. CALPHAD Comput. Coupling Phase Diagr. Thermochem. 26, 273–312 (2002)

H.L. Lukas, S.G. Fries, B. Sundman, Computational Thermodynamics: The CALPHAD Method (Cambridge University Press, Cambridge, 2007)

R.B. Tuttle, S.R. Kottala, Population size distribution of rare earth and non-metallic inclusions in 4130 and 8630 steels. Int. J. Metalcast. 12(4), 884–896 (2018)

R.B. Tuttle, Effect of austenite fraction on rare earth grain refinement, in Proceedings of the 121st Metalcasting Congress (2017)

R. Tuttle, K. Song, Characterization of rare earth inclusions from cast 1010 steel. Int. J. Metalcast. 9(1), 23–31 (2015)

R.B. Tuttle, Grain refinement in plain carbon steels. Trans. Am. Foundry Soc. 118, 425–435 (2010)

J. Haakosen, J. Solberg, O. Klevan, van der Eijk, C., Grain refinement of austenitic manganese steels, in Proceedings of the 59th Electric Furnace Conference, vol. II (2011), pp. 763–771

E.F. Nordstrand, O. Grong, C. Van Der Eijk, S. Gaal, Phase relations in Ce–Al–Fe–S based grain refiners for steels. ISIJ Int. 49, 1051–1058 (2009)

H. Suito, H. Ohta, S. Morioka, Refinement of solidification microstructure and austenite grain by fine inclusion particles. ISIJ Int. 46, 840–846 (2006)

B.L. Bramfitt, Effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Met. Trans. 1, 1987–1995 (1970)

D. Stefanescu, Science and Engineering of Casting Solidification (Springer, Berlin, 2015)

Acknowledgements

The authors would like to thank the Office of Naval Research for financially supporting this work under Award Number N000141712766. Appreciation to Tyler Schramski and Hunter Towalski is also extended for their efforts in producing the material for this work. The authors value MeltLab’s assistance in understanding the practicalities of thermal analysis and modifying their software based on our discussions to provide a better steel analysis. Support from FOSECO through for their donations of various consumables for conducting these experiments was invaluable. Lastly, Jennie Tuttle’s efforts in editing this paper are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tuttle, R., Kapadia, H.A. Thermal Analysis of Rare Earth Grain Refined 4130. Inter Metalcast 13, 273–285 (2019). https://doi.org/10.1007/s40962-018-0274-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-0274-8