Abstract

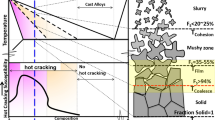

In this study, the effect of alloy composition on uniaxial tensile properties of Al–Zn–Mg–Cu alloys was investigated using seven distinctive alloy compositions. The sample alloys were manufactured as net-shaped components using the controlled diffusion solidification technology coupled with the tilt pour gravity casting process. The effect of T4 and T6 heat treatment on the castings was investigated using seven alloy compositions with the total alloying content (Zn + Mg + Cu) varying from 4.6 to 10.6 wt%. The uniaxial tensile yield strengths (0.2% proof stress) of the respective alloys were measured for T4 temper and varied between 125 and 316 MPa and for the T6 temper samples varied between 280 and 540 MPa. A quantitative image analysis was carried out to measure the eutectic phase fraction, which was compared with predictions from thermodynamic solidification simulations. The experimental phase characterization of various secondary phases/precipitates was conducted using an electron microscopy (STEM) methodology along with energy dispersive spectroscopy (EDS) results; other experimental method such as the Archimedes’ density measurements was also used to evaluate porosity content in the samples.

Similar content being viewed by others

References

L. Cheah, J. Heywood, R. Kirchain, in IEEE International Symposium on Sustainable Systems and Technology (ISSST), 2010

U.S. Environmental Protection Agency, Assessment and Standards Division, Office of Transportation and Air Quality, EPA-420-D-09-003 (2009)

I.J. Polmear, Light Alloys From Traditional Alloys to Nano-crystals, 4th edn. (Butterworth-Heinemann, Oxford, 2006)

J.E. Hatch, Aluminum: Properties and Physical Metallurgy (American Society for Metals (ASM), Ohio, 1984)

R. Ghiaasiaan, X. Zeng, S. Shankar, Mater. Sci. Eng. A 594, 260 (2014)

R. Ghiaasiaan, S. Shankar, D. Apelian, in TMS Conference, San Diego, CA, USA, 2014

S.R. Ghiaasiaan, Ph.D. Thesis, McMaster University, Hamilton, Ontario, Canada, 2015

R. Ghiaasiaan, B. Shalchi-amirkhiz, S. Shankar, Mater. Sci. Eng. A 698, 206 (2017)

G. Birsan, P. Ashtari, S. Shankar, Int. J. Cast Met. Res. 24(6), 378 (2011)

A.A. Khalaf, S. Shankar, Metall. Mater. Trans. A 42, 2456 (2011)

A.A. Khalaf, S. Shankar, J. Mater. Sci. 47, 8153 (2012)

A.A. Khalaf, Acta Mater. 103, 301 (2016)

A. Deschamps, Y. Breâchet, Acta Mater. 47(1), 293 (1999)

M.J. Starink, S.C. Wang, Acta Mater. 51, 5131 (2003)

M. Dixit, R.S. Mishra, K.K. Sankaran, Mater. Sci. Eng. A 478, 163 (2008)

L.F. Mondolfo, Metall. Rev. 153, 94–95 (1971)

H. Loffler, I. Kovacs, J. Lendvai, J. Mater. Sci. 18, 2215 (1983)

M.D. David, R.D. Foley, J.A. Griffin, C.A. Monroe, Int. J. Metalcast. 10, 1–2 (2016)

M.D. David, R.D. Foley, J.A. Griffin, Int. Metalcast. 10, 2 (2016)

H. Akhyar, Husaini, Int. Metalcast. 10, 452 (2016)

J.D. Robson, P.B. Prangnell, Acta Mater. 49, 599 (2001)

M.F. Ibrahim, G.H. Garza-Elizondo, A.M. Samuel, F.H. Samuel, Int. J. Metalcast. 10, 264 (2016)

Pandat thermodynamic simulation software with PanAl2014 database; Computherm LLC. http://www.computherm.com/. Accessed Dec 2014.

Eberbach (Corporation, ANN Michigan) equipped with an image processing software: NIS BR 3.10 image acquisition system

ImageJ, Image processing and Analysis in Java, 1.42q Java 1.6.0 (32 bit)

ASM Handbook committee, Metals Handbook, Metallographic, Structure and Phase diagram, vol. 8, 8th edn. (American Society for Metals, Milton Park, 1973)

N.E. Mazibuko, U.A. Curle, Mater. Sci. Forum 690, 343 (2011)

F. Czerwinski, Magnesium Injection Molding (Springer, Berlin, 2008), pp. 280–281

ASTM B328-96(2003)e1, Standard Test Method for Density, Oil Content, and Interconnected Porosity of Sintered Metal Structural Parts and Oil-Impregnated Bearings (Withdrawn 2009). (ASTM International, West Conshohocken, 2003). https://doi.org/10.1520/b0328-96r03e01. www.astm.org. Accessed Dec 2014.

D.A. Porter, Kenneth E. Easterling, M.Y. Sherif, Phase Transformations in Metals and Alloys, 3rd edn. (Taylor & Francis Group, Milton Park, 2009)

R.L. Fleischer, Acta Metall. 11, 203 (1963)

N.F. Mott, F.R.N. Nabarro, Phys. Soc. Lond. 1, 271 (1984)

R. Labusch, Phys. Status Solidi 41, 659 (1970)

D.K. Xu, N. Birbilis, P.A. Rometsch, Corros. Sci. 54, 17 (2012)

W. Kurz, D.J. Fisher, (Trans Tech Publications, Switzerland-Germany-UK-USA, 1986)

T.Y. Ahn, J.G. Jung, E.J. Baek, S.S. Hwang, K. Euh, J. Alloys Compd. 701(15), 660 (2017)

F. Jiang, H.S. Zurob, G.R. Purdy, H. Zhang, Mater. Charact. 117, 47 (2016)

I. Kalem, C. Hamilton, S. Dymek, Mater. Des. 60, 295 (2014)

W. Huo, L. Hou, Y. Lang, H. Cui, L. Zhuang, J. Zhang, Mater. Sci. Eng. A 626, 86 (2015)

E.O. Hall, Proc. Phys. Soc. Lond. 643, 747 (1951)

N.J. Petch, J. Iron Steel Inst. Lond. 173, 25 (1953)

G.E. Dieter, Mechanical Metallurgy (McGraw Hill Book Company (UK) limited, New York, 1988)

J.D. Embury, D.J. Lloyd, T.R. Ramachandran, in Aluminum Alloys—Contemporary Research and Applications, (Treatise on Materials Science and Technology, vol. 31, ed. by A.K. Vasudevan, R.D. Doherty (Academic Press Inc, Boston, 1989)

M. Lalpoor, D.G. Eskin, L. Katgerman, Mater. Sci. Eng. A 497, 186 (2008)

D.H. Kirkwood, Mater. Des. 21, 387 (2000)

M.C. Flemings, Metall. Mater. Trans. B 22, 269 (1991)

Mill Certificate, Al 7050 Product data sheet (ALCOA worldwide, 2013). http://www.alcoa.com. Accessed Dec 2014.

ASM International, ASM Handbook: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (ASM International, Materials Park, 1990)

V.V. Ravikumar, S. Kumaran, Int. J. Miner. Metall. Mater. 24(2), 179 (2017)

W.W. Wang, B.B. Jia, S.J. Luo, Trans. Nonferrous Met. Soc. China 19, 337 (2009)

Z. Li, B. Xiong, Y. Zhang, B. Zhu, F. Wang, H. Liu, J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 14–3, 246 (2007)

A.J. Morris, R.F. Robey, P.D. Couch, E. De los Rios, Mater. Sci. Forum 242, 181 (2007)

X. Peng, Q. Guo, X. Liang, Y. Deng, Y. Gu, G. Xu, Z. Yin, Mater. Sci. Eng. A 688(14), 146 (2017)

Acknowledgements

The author expresses his gratitude to the Natural Sciences and Engineering Research Council (NSERC) of Canada for their financial support through the Discovery Grant programme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghiaasiaan, R., Shankar, S. Effect of Alloy Composition on Microstructure and Tensile Properties of Net-Shaped Castings of Al–Zn–Mg–Cu Alloys. Inter Metalcast 13, 300–310 (2019). https://doi.org/10.1007/s40962-018-0254-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-0254-z