Abstract

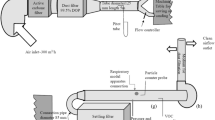

We studied formaldehyde emission from uncoated particleboard with 16-mm thickness using the large chamber and the desiccator method. A chamber of 28.4 m3 was installed to simulate a mobile home. The formaldehyde off-gassing properties of particleboard were evaluated using the chamber. The relationship between the concentration obtained by the chamber and the values by the desiccator test was discussed in this study under different conditions of conditioning day, air exchange, and loading ratio. These two methods were compared and discussed regarding the formaldehyde emission level. Three loading ratios, 0.429 m2/m3, 0.264 m2/m3, and 0.132 m2/m3, were chosen to represent different applications of particleboard products. There was strong correlation between emissions and air exchange rates at equal product-loading ratios in the large chamber, the related coefficient R 2 exceeded 0.90. There was also an indication of a generic correlation between the large chamber and the two-hour desiccator test with a single product designated loading ratio, air exchange rate, and climatic conditions.

Similar content being viewed by others

References

ASTM D5582-00. 2006. Standard test method for determining formaldehyde levels from wood products using a desiccator.

JAS 233-2003. The Japanese agriculture standards of plywood paneling.

JIS A 1460-2001. Building boards determination of formaldehyde emission—Desiccator method.

JIS A 1901–2003. Small chamber method—determination of the emission of volatile organic compounds and aldehydes for building products.

Myers GE. 1984. How mole ratio of UF resin affects formaldehyde emission and other properties: A literature critique. Forest Products Journal, 34(5): 35–41.

Risholm-Sundmana M, Larsen A, Vestin E, Weibull A. 2007. Formaldehyde emission-comparison of different standard methods. Atmospheric Environment, 41(15): 3193–3202.

Meyer B, Johns WE, Woo JK. 1980. Formaldehyde release from sulfur-modified urea-formaldehyde resin systems. Forest Products Journal, 30(3): 24–31.

Que ZL, Furuno T, Katoh S, Nishino Y. 2007. The mathematical model for the formaldehydeemission from wood-based board in room. Building and Environment, 42(6): 2321–2324.

Que ZL, Furuno T. 2007. Formaldehyde emission from wood products: relationship between the values by the Chamber method and those by the Desiccator test. Wood Science and Technology, 41(3): 267–279.

Roffael E. 1975. Messung der formaldehydehydabgabe. Holz-zentralblatt, 100(96): 1461–1462.

Tohmura S, Inoue A, Guo L. 1998. The correlation of formaldehyde emission with the chemical structure of cured urea-formaldehyde resins. Mokuzai Gakkaishi, 44(6): 433–440.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation project: This work was supported by the Special Fund of key discipline-Wood Science and Technology Zhejiang A & F University (Project 201203) and Jiangsu Overseas Research & Training Program for University Prominent Young & Middle-aged Teachers and Presidents

Rights and permissions

About this article

Cite this article

Que, Zl., Wang, Fb., Ma, Lf. et al. Evaluation of formaldehyde emission from particleboard using the large chamber and desiccator method at various loading ratios. Journal of Forestry Research 24, 137–142 (2013). https://doi.org/10.1007/s11676-013-0333-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11676-013-0333-1