Abstract

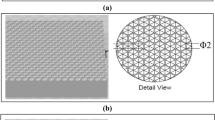

Biodegradable Zn-0.05Mg-(0.5, 1 wt.%) Ag alloy was manufactured by indirectly extruding the alloy ingot at 200 °C with an extrusion ratio of 16:1. Dynamic recrystallization took place during the extrusion process, leading to the formation of equiaxed crystals with twins in both cross-sectional and longitudinal direction. There was no detectable Ag-related phase present except the Mg2Zn11 in the alloys. Tensile strength was increased with an increase in Ag content, reaching 202 MPa when Ag content is 1 wt.%. As-extruded Zn-0.05Mg-0.5Ag showed better corrosion performance with a low corrosion current density of 2.2 A/cm2 and low corrosion rate of 0.15 mm/year. The antibacterial property improved for both Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli) by addition of Ag. The antibacterial rates were more than 99% when Ag content is up to 1 wt.%. The biodegradable Zn-Mg-Ag alloys with high antibacterial behavior show great potential in medical devices.

Similar content being viewed by others

Change history

23 October 2019

The article “Morphology and Mechanical, Corrosive, and Antibacterial Behaviors of Indirectly Extruded Zn-0.05 wt.%Mg-(0.5, 1 wt.%)Ag Alloys”, written by C. Xiao, D. W. Zhao, Q. Sun, Y. Su, D. P. Cui, X. Z. Zhang, X. L. Dong, H. X. Wang, F. Wang, Y. P. Ren, and G. W. Qin, was originally published electronically on the publisher’s internet portal (currently SpringerLink) on 11 September 2019 with open access. With the author(s)’ decision to step back from Open Choice, the copyright of the article changed in October 2019 to © ASM International 2019 and the article is forthwith distributed under the terms of copyright.

References

P.K. Bowen, J. Drelich, and J. Goldman, Zinc Exhibits Ideal Physiological Corrosion Behavior for Bioabsorbable Stents, Adv. Mater., 2013, 25(18), p 2577–2582

G.K. Levy, J. Goldman, and E. Aghion, The Prospects of Zinc as a Structural Material for Biodegradable Implants—A Review Paper, Metals, 2017, 7(10), p 402

X. Liu, J. Sun, K. Qiu, Y. Yang, Z. Pu, L. Li, and Y. Zheng, Effects of Alloying Elements (Ca and Sr) on Microstructure, Mechanical Property and In Vitro Corrosion Behavior of Biodegradable Ternary Zn-1.5Mg Alloy, J. Alloys Compd., 2016, 664, p 444–452

S.Y. Liu, D. Kent, N. Doan, M. Dargusch, and G. Wang, Effects of Deformation Twinning on the Mechanical Properties of Biodegradable Zn-Mg Alloys, Bioact. Mater., 2019, 4(1), p 8–16

H.B. Gong, K. Wang, R. Strich, and J.G. Zhou, In vitro Biodegradation Behavior, Mechanical Properties, and Cytotoxicity of Biodegradable Zn–Mg alloy, J. Biomed. Mater. Res. B Appl. Biomater., 2015, 130(8), p 1632–1640

H.F. Li, H.T. Yang, Y.F. Zheng, F.Y. Zhou, K.J. Qiu, and X. Wang, Design and Characterizations of Novel Biodegradable Ternary Zn-Based Alloys with IIA Nutrient Alloying Elements Mg, Ca and Sr, Mater. Des., 2015, 83, p 95–102

Z.B. Tang, J.L. Niu, H. Huang, H. Zhang, J. Pei, J.M. Ou, and G.Y. Yuan, Potential Biodegradable Zn-Cu Binary Alloys Developed for Cardiovascular Implant Applications, J. Mech. Behav. Biomed. Mater., 2017, 72, p 182–191

Z.B. Tang, H. Huang, J.L. Niu, L. Zhang, H. Zhang, J. Pei, J.Y. Tan, and G.Y. Yuan, Design and Characterizations of Novel Biodegradable Zn-Cu-Mg Alloys for Potential Biodegradable Implants, Mater. Des., 2017, 117, p 84–94

J. Kubásek, D. Vojtěch, E. Jablonská, I. Pospíšilová, J. Lipov, and T. Ruml, Structure, Mechanical Characteristics and In Vitro Degradation, Cytotoxicity, Genotoxicity and Mutagenicity of Novel Biodegradable Zn–Mg Alloys, Mater. Sci. Eng. C, 2016, 58, p 24–35

X. Liu, J. Sun, F. Zhou, Y. Yang, R. Chang, K. Qiu, Z. Pu, L. Li, and Y. Zheng, Micro-Alloying with Mn in Zn-Mg Alloy for Future Biodegradable Metals Application, Mater. Des., 2016, 94, p 95–104

M.S. Dambatta, S. Izman, D. Kurniawan, and H. Hermawan, Processing of Zn-3Mg Alloy by Equal Channel Angular Pressing for Biodegradable Metal Implants, J. King Saud Univ. Sci., 2017, 29(4), p 455–461

S.N. Sun, Y.P. Ren, L.Q. Wang, B. Yang, and G.W. Qin, Room Temperature Quasi-Superplasticity Behavior of Backward Extruded Zn–15Al Alloys, Mater. Sci. Eng. A, 2016, 676, p 336–341

H.L. Jin, S. Zhao, R. Guillory, P.K. Bowen, Z.Y. Yin, A. Griebel, J. Schaffer, E.J. Earley, J. Goldman, and J.W. Drelich, Novel High-Strength, Low-Alloys Zn-Mg (< 0.1 wt.%Mg) and Their Arterial Biodegradation, Mater. Sci. Eng. C, 2018, 84, p 67–79

N. Hadrup and H.R. Lam, Oral Toxicity of Silver Ions, Silver Nanoparticles and Colloidal Silver—A Review, Regul. Toxicol. Pharmacol., 2014, 68(1), p 1–7

G. Grass, C. Rensing, and M. Solioz, Metallic Copper as an Antimicrobial Surface, Appl. Environ. Microb., 2011, 77(5), p 1541–1547

W.K. Jung, H.C. Koo, K.W. Kim, S. Shin, S.H. Kim, and Y.H. Park, Antibacterial Activity and Mechanism of Action of the Silver Ion in Staphylococcus aureus and Escherichia coli, Appl. Environ. Microb., 2008, 74(7), p 2171–2178

B.B. Zhang, Y.F. Zheng, and Y. Liu, Effect of Ag on the Corrosion Behavior of Ti–Ag Alloys in Artificial Saliva Solutions, Dent. Mater., 2009, 25(5), p 672–677

E.L. Zhang, X.Y. Wang, M. Chen, and B. Hou, Effect of the Existing Form of Cu Element on the Mechanical Properties, Bio-Corrosion and Antibacterial Properties of Ti-Cu Alloys for Biomedical Application, Mater. Sci. Eng. C, 2016, 69, p 1210–1221

L. Ren, Z. Ma, M. Li, Y. Zhang, W. Liu, Z. Liao, and K. Yang, Antibacterial Properties of Ti-6Al-4V-xCu Alloys, J. Mater. Sci. Technol., 2014, 30(7), p 699–705

A. Simchi, E. Tamjid, F. Pishbin, and A.R. Boccaccini, Recent Progress in Inorganic and Composite Coatings with Bactericidal Capability for Orthopaedic Applications, Nanomed. Nanotechnol. Lett., 2011, 7(1), p 22–39

K. Baba, R. Hatada, S. Flege, W. Ensinger, Y. Shibata, J. Nakashima, T. Sawase, and T. Morimura, Preparation and Antibacterial Properties of Ag-Containing Diamond-Like Carbon Films Prepared by a Combination of Magnetron Sputtering and Plasma Source Ion Implantation, Vacuum, 2013, 89, p 179–184

W. Shao and Q. Zhao, Influence of Reducers on Nanostructure and Surface Energy of Silver Coatings and Bacterial Adhesion, Surf. Coat. Technol., 2010, 204(8), p 1288–1294

M. Sikora-Jasinska, E. Mostaed, A. Mostaed, R. Beanland, D. Mantovani, and M. Vedani, Fabrication, Mechanical Properties and In Vitro Degradation Behavior of Newly Developed Zn\Ag Alloys for Degradable Implant Applications, Mater. Sci. Eng. C, 2017, 77, p 1170–1181

L.Q. Wang, Y.F. He, H. Zhao, H.B. Xie, S. Li, Y.P. Ren, and G.W. Qin, Effect of Cumulative Strain on the Microstructural and Mechanical Properties of Zn-0.02 wt.%Mg Alloy Wires During Room-Temperature Drawing Process, J. Alloys Compd., 2018, 740, p 949–957

C. Xiao, L.Q. Wang, Y.P. Ren, S.N. Sun, E.L. Zhang, C.N. Yuan, Q. Li, X.G. Sun, F.Y. Shou, J.Z. Duan, H. Wang, and G.W. Qin, Indirectly Extruded Biodegradable Zn-0.05 wt.%Mg Alloy with Improved Strength and Ductility: In Vitro and In Vivo Studies, J. Mater. Sci. Technol., 2018, 34(9), p 1327–1618

Z.L. Liu, F. Wang, D. Qiu, J.A. Taylor, and M.X. Zhang, The Effect of Solute Elements on the Grain Refinement of Cast Zn, Metall. Mater. Trans. A, 2013, 44(9), p 4025–4030

T. Ogura, T. Otani, A. Hirose, and T. Sato, Improvement of Strength and Ductility of an Al–Zn–Mg Alloy by Controlling Grainsize and Precipitate Microstructure with Mn and Ag Addition, Mater. Sci. Eng. A, 2013, 580, p 288–293

G. Ben-Hamu, D. Eliezer, A. Kaya, Y.G. Na, and K.S. Shin, Microstructure and Corrosion Behavior of Mg–Zn–Ag Alloys, Mater. Sci. Eng. A, 2006, 435–436, p 579–587

D.A. Butts and W.F. Gale, 11-Equilibrium Diagrams, Smithells Metals Reference Book, 2nd ed., W.F.G.C. Totemeier, Ed., Butterworth-Heinemann, Oxford, 2004, p 1–534

C. Wang, Z.T. Yu, Y.J. Cui, Y.F. Zhang, S. Yu, G.Q. Qu, and H.B. Gong, Processing of a Novel Zn Alloy Micro-Tube for Biodegradable Vascular Stent Application, J. Mater. Sci. Technol., 2016, 32(9), p 925–929

R. Yue, H. Huang, G.Z. Ke, H. Zhang, J. Pei, G.H. Xue, and G.Y. Yuan, Microstructure, Mechanical Properties and In Vitro Degradation Behavior of Novel Zn-Cu-Fe Alloys, Mater. Charact., 2017, 134, p 114–122

K.B. Törne, F.A. Khan, A. Örnberg, and J. Weissenrieder, Zn–Mg and Zn–Ag Degradation Mechanism Under Biologically Relevant Conditions, Surf. Innov., 2018, 6(1), p 81–92

S. Hiromoto, Corrosion of Metallic Biomaterials, Woodhead Publishing Series in Biomaterials, Metals for Biomedical Devices, M. Niimomi, Ed., Woodhead Publishing, Sawston, 2010, p 99–121

M.M. Alves, T. Prošek, C.F. Santos, and M.F. Montemor, Evolution of the In Vitro Degradation of Zn–Mg Alloys Under Simulated Physiological Conditions, RSC Adv., 2017, 7(45), p 28224–28233

B.N. Mordyuk, O.P. Karasevskaya, and G.I. Prokopenko, Structurally induced enhancement in corrosion resistance of Zr-2.5%Nb alloy in saline solution by applying ultrasonic impact peening, Mater. Sci. Eng. A, 2013, 559, p 453–461

N.I. Khripta, O.P. Karasevska, and B.N. Mordyuk, Surface Layers of Zr-18%Nb Alloy Modified by Ultrasonic Impact Treatment: Microstructure, Hardness and Corrosion, J. Mater. Eng. Perform., 2017, 26(11), p 5446–5455

H.F. Li, X.H. Xie, Y.F. Zheng, Y. Cong, F.Y. Zhou, K.J. Qiu, X. Wang, S.H. Chen, L. Huang, L. Tian, and L. Qin, Development of Biodegradable Zn-1X Binary Alloys with Nutrient Alloying Elements Mg, Ca and Sr, Sci. Rep., 2015, 5, p 10719

Y.P. Xie, Y.P. He, P.L. Irwin, T. Jin, and X.M. Shi, Antibacterial Activity and Mechanism of Action of Zinc Oxide Nanoparticles Against Campylobacter jejuni, Environ. Microbiol., 2011, 77(7), p 2325–2331

P. Petrini, C.R. Arciola, I. Pezzali, S. Bozzini, L. Montanaro, M.C. Tanzi, P. Speziale, and L. Visai, Antibacterial Activity of Zinc Modified Titanium Oxide Surface, Int. J. Artif. Organs, 2006, 29(4), p 434–442

O. Akhavan and E. Ghaderi, Enhancement of antibacterial properties of Ag nanorods by electric field, Sci. Technol. Adv. Mater., 2009, 10(1), p 015003

D. Tie, F. Feyerabend, W.D. Müller, R. Schade, K. Liefeith, K.U. Kainer, and R. Willumeit, Antibacterial Biodegradable Mg-Ag Alloys, Eur. Cells Mater., 2013, 25, p 284–298

Z.D. Liu, R. Schade, B. Luthringer, N. Hort, H. Rothe, S. Müller, K. Liefeith, R. Willumeit-Römer, and F. Feyerabend, Influence of the microstructure and silver content on degradation, cytocompatibility, and antibacterial properties of magnesium-silver alloys, in vitro, Oxid. Med. Cell. Longev., 2017, https://doi.org/10.1155/2017/8091265

Y. Xie, L.C. Zhao, Z. Zhang, X. Wang, R. Wang, and C.X. Cui, Fabrication and Properties of Porous Zn-Ag Alloy Scaffolds as Biodegradable Materials, Mater. Chem. Phys., 2018, 219, p 433–443

Acknowledgments

This project was supported by the National Natural Science Foundation of China (81672139), Postdoctoral Science Foundation of China (No.: 194016), Doctoral Research Starting Foundation of Affiliated Zhongshan Hospital of Dalian University (No.: DLDXZSYY-BK201703), and Doctoral Research Starting Foundation of Dalian University (No.: 20152QL002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original article has been corrected: This article was originally published electronically on the publisher’s internet portal (currently SpringerLink) on 11 September 2019 with open access. With the author(s)’ decision to step back from Open Choice, the copyright of the article changed in October 2019 to © ASM International 2019 and the article is forthwith distributed under the terms of copyright.

Rights and permissions

About this article

Cite this article

Xiao, C., Zhao, D.W., Sun, Q. et al. Morphology and Mechanical, Corrosive, and Antibacterial Behaviors of Indirectly Extruded Zn-0.05wt.%Mg-(0.5, 1 wt.%)Ag Alloys. J. of Materi Eng and Perform 28, 6864–6872 (2019). https://doi.org/10.1007/s11665-019-04297-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04297-4