Abstract

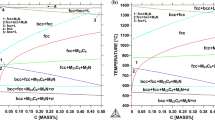

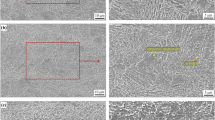

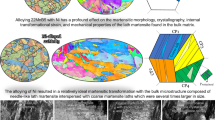

A 5 nm Ni-rich nanolayer has been introduced along nanoscale martensite/austenite phase boundaries (PBs) by one-step low-temperature annealing treatment of cold-rolled meta-stable austenitic steels. Control experiments reveal that the martensitic phase transformation kinetics can be significantly altered by presence of the nanolayers. The growth of pre-existed martensites is substantially suppressed while the martensite nucleation in austenites is less affected, as revealed by a statistical investigation on the martensite size distribution under different tensile strains. Enhanced strength and excellent ductility have been achieved simultaneously in the annealed samples, demonstrating that PBs can be effectively engineered to achieve optimized mechanical properties.

Similar content being viewed by others

References

Kim H, Lee J, Barlat F, et al. Experiment and modeling to investigate the effect of stress state, strain and temperature on martensitic phase transformation in TRIP-assisted steel. Acta Mater, 2015, 97: 435–44.

Vinogradov A, Lazarev A, Linderov M, et al. Kinetics of deformation processes in high-alloyed cast transformation-induced plasticity/twinning-induced plasticity steels determined by acoustic emission and scanning electron microscopy: Influence of austenite stability on deformation mechanisms. Acta Mater, 2013, 61: 2434–244.

Zhu R, Li S, Karaman I, et al. Multi-phase microstructure design of a low-alloy TRIP-assisted steel through a combined computational and experimental methodology. Acta Mater, 2012, 60: 3022–303.

Raabe D, Sandlöbes S, Millán J, et al. Segregation engineering enables nanoscale martensite to austenite phase transformation at grain boundaries: A pathway to ductile martensite. Acta Mater, 2013, 61: 6132–615.

Kuzmina M, Ponge D, Raabe D. Grain boundary segregation engineering and austenite reversion turn embrittlement into toughness: Example of a 9 wt.% medium Mn steel. Acta Mater, 2015, 86: 182–192

Kuzmina M, Herbig M, Ponge D, et al. Linear complexions: Confined chemical and structural states at dislocations. Science, 2015, 349: 1080–108.

Edmonds D V, He K, Rizzo F C, et al. Quenching and partitioning martensite—A novel steel heat treatment. Mater Sci Eng-A, 2006, 438–440: 25–3.

Lu X, Liu H, Jin X. Preliminary study on kinetics of carbon partitioning in a high Ni Q&P steel. J Alloys Compd, 2013, 577: S72–S75

Zamberger S, Whitmore L, Krisam S, et al. Experimental and computational study of cementite precipitation in tempered martensite. Model Simul Mater Sci Eng, 2015, 23: 05501.

Dmitrieva O, Ponge D, Inden G, et al. Chemical gradients across phase boundaries between martensite and austenite in steel studied by atom probe tomography and simulation. Acta Mater, 2011, 59: 364–374

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Zhang, Y., Liu, J. & Wang, H. Alter martensitic phase transformation kinetics by forming Ni-rich nanolayer in metastable austenitic steels. Sci. China Technol. Sci. 62, 546–550 (2019). https://doi.org/10.1007/s11431-018-9401-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9401-3