Abstract

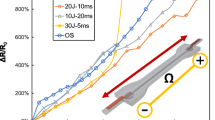

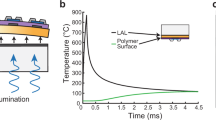

It is increasingly crucial for flexible electronics to efficiently and reliably peel large-area, ultra-thin flexible films off from rigid substrate serving as substrates of flexible electronics device, especially in industrial production. This paper experimentally investigated the mechanism and technologic characteristics of laser lift-off (LLO) process of ultra-thin (~ 2 μm) polyimide (PI) film. It was found increasingly difficult to obtain desirable ultra-thin PI film by LLO with the decrease of the film thickness. The optimal process parameters were achieved considering laser fluence and accumulated irradiation times (AIT), which were found to be strongly correlative to the thickness of PI film. The process mechanism of LLO of PI film was disclosed that laser ablation of interfacial PI will result in the formation of gas products between the PI and glass substrate, enabling the change of interface microstructures to reduce the interface bond strength. The amount of gas products mainly determines the result of LLO process for ultra-thin PI film, from residual adhesion to wrinkles or cracking. The strategy of multi-scanning based on multiple irradiations of low-energy laser pulses was presented to effectively achieve a reliable LLO process of ultra-thin PI film. This study provides an attractive route to optimize the LLO process for large-scale production of ultra-thin flexible electronics.

Similar content being viewed by others

References

Dong W T, Xiao L, Zhu C, et al. Theoretical and experimental study of 2D conformability of stretchable electronics laminated onto skin. Sci China Technol Sci, 2017, 60: 1415–1422

Guo R, Wang X L, Yu W Z, et al. A highly conductive and stretchable wearable liquid metal electronic skin for long-term conformable health monitoring. Sci China Technol Sci, 2018, 61: 1031–1037

Cui Y, Li Y, Xing Y, et al. Three-dimensional thermal analysis of rectangular micro-scale inorganic light-emitting diodes integrated with human skin. Int J Thermal Sci, 2018, 127: 321–328

Li Y, Zhang J, Xing Y, et al. Thermomechanical analysis of epidermal electronic devices integrated with human skin. J Appl Mech, 2017, 84: 111004

Vosgueritchian M, Tok J B H, Bao Z. Light-emitting electronic skin. Nat Photon, 2013, 7: 769–771

Sekitani T, Nakajima H, Maeda H, et al. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat Mater, 2009, 8: 494–499

Su Y, Li S, Huan Y, et al. The universal and easy-to-use standard of voltage measurement for quantifying the performance of piezoelectric devices. Extreme Mech Lett, 2017, 15: 10–16

Su Y, Dagdeviren C, Li R. Measured output voltages of piezoelectric devices depend on the resistance of voltmeter. Adv Funct Mater, 2015, 25: 5320–5325

Huang Y A, Ding Y, Bian J, et al. Hyper-stretchable self-powered sensors based on electrohydrodynamically printed, self-similar piezoelectric nano/microfibers. Nano Energy, 2017, 40: 432–439

Gui H, Tan S C, Wang Q, et al. Spraying printing of liquid metal electronics on various clothes to compose wearable functional device. Sci China Technol Sci, 2017, 60: 306–316

Bian J, Ding Y, Duan Y, et al. Buckling-driven self-assembly of selfsimilar inspired micro/nanofibers for ultra-stretchable electronics. Soft Matter, 2017, 13: 7244–7254

Dagdeviren C, Su Y, Joe P, et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat Commun, 2014, 5: 4496

Xu S, Zhang Y, Jia L, et al. Soft microfluidic assemblies of sensors, circuits, and radios for the skin. Science, 2014, 344: 70–74

Meitl M A, Zhu Z T, Kumar V, et al. Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat Mater, 2006, 5: 33–38

Gao Y, Li Y, Li R, et al. An accurate thermomechanical model for laser-driven microtransfer printing. J Appl Mech, 2017, 84: 064501

Xue Y, Zhang Y, Feng X, et al. A theoretical model of reversible adhesion in shape memory surface relief structures and its application in transfer printing. J Mech Phys Solids, 2015, 77: 27–42

Hwang G T, Park H, Lee J H, et al. Self-powered cardiac pacemaker enabled by flexible single crystalline PMN-PT piezoelectric energy harvester. Adv Mater, 2014, 26: 4880–4887

Shahrjerdi D, Bedell S W. Extremely flexible nanoscale ultrathin body silicon integrated circuits on plastic. Nano Lett, 2012, 13: 315–320

Zhai Y, Mathew L, Rao R, et al. High-performance flexible thin-film transistors exfoliated from bulk wafer. Nano Lett, 2012, 12: 5609–5615

Hwang G T, Im D, Lee S E, et al. In vivo silicon-based flexible radio frequency integrated circuits monolithically encapsulated with biocompatible liquid crystal polymers. ACS Nano, 2013, 7: 4545–4553

Burghartz J N, Appel W, Rempp H D, et al. A new fabrication and assembly process for ultrathin chips. IEEE Trans Electron Devices, 2009, 56: 321–327

Lee C H, Kim S J, Oh Y, et al. Use of laser lift-off for flexible device applications. J Appl Phys, 2010, 108: 102814

Delmdahl R, Pätzel R, Brune J. Large-area laser-lift-off processing in microelectronics. Phys Procedia, 2013, 41: 241–248

Kim K, Kim S Y, Lee J L. Flexible organic light-emitting diodes using a laser lift-off method. J Mater Chem C, 2014, 2: 2144–2149

Kim S, Son J H, Lee S H, et al. Flexible crossbar-structured resistive memory arrays on plastic substrates via inorganic-based laser lift-off. Adv Mater, 2014, 26: 7480–7487

Park K I, Son J H, Hwang G T, et al. Highly-efficient, flexible piezoelectric PZT thin film nanogenerator on plastic substrates. Adv Mater, 2014, 26: 2514–2520

Joe D J, Kim S, Park J H, et al. Laser-material interactions for flexible applications. Adv Mater, 2017, 29: 1606586

Delmdahl R, Fricke M, Fechner B. Laser lift-off systems for flexibledisplay production. J Inf Display, 2014, 15: 1–4

Joshi S, Savov A, Dekker R. Substrate transfer technology for stretchable electronics. Procedia Eng, 2016, 168: 1555–1558

MacCarthy N, Wood T, Ameri H, et al. A laser release method for producing prototype flexible retinal implant devices. Senss Actuators A-Phys, 2006, 132: 296–301

Lifka, H, Tanase, C, McCulloch, D, et al. Ultra-Thin Flexible OLED Device, SID Symposium Digest of Technical Papers, Wiley Online Library, 2007. 1599–1602

Gao X, Lin L, Liu Y, et al. LTPS TFT process on polyimide substrate for flexible AMOLED. J Display Technol, 2015, 11: 666–669

Kim S J, Lee H E, Choi H, et al. High-performance flexible thermoelectric power generator using laser multiscanning lift-off process. ACS Nano, 2016, 10: 10851–10857

Dang B, Andry P, Tsang C, et al. CMOS compatible thin wafer processing using temporary mechanical wafer, adhesive and laser release of thin chips/wafers for 3D integration. In: 2010 60th Electronic Components and Technology Conference (ECTC). IEEE, 2010. 1393–1398

Liu Z X, Tang P P, Huang Y A, et al. Experimental estimation of adhesive fracture energy of compliant adhesive tape. In: 2014 15th International Conference on Electronic Packaging Technology (ICEPT). IEEE, 2014. 842–846

Doany F E, Narayan C. Laser release process to obtain freestanding multilayer metal-polyimide circuits. IBM J Res Dev, 1997, 41: 151–157

Küper S, Brannon J, Brannon K. Threshold behavior in polyimide photoablation: Single-shot rate measurements and surface-temperature modeling. Appl Phys A, 1993, 56: 43–50

Babu S V, D’couto G C, Egitto F D. Excimer laser induced ablation of polyetheretherketone, polyimide, and polytetrafluoroethylene. J Appl Phys, 1992, 72: 692–698

D’couto G, Babu S. Heat transfer and material removal in pulsed excimer-laser-induced ablation: Pulsewidth dependence. J Appl Phys, 1994, 76: 3052–3058

Singleton D L, Paraskevopoulos G, Irwin R S. XeCl laser ablation of polyimide: Influence of ambient atmosphere on particulate and gaseous products. J Appl Phys, 1989, 66: 3324–3328

Park J, Sin Y G, Kim J H, et al. Dependence of adhesion strength between GaN LEDs and sapphire substrate on power density of UV laser irradiation. Appl Surf Sci, 2016, 384: 353–359

Ding Y, Zhu C, Liu J, et al. Flexible small-channel thin-film transistors by electrohydrodynamic lithography. Nanoscale, 2017, 9: 19050–19057

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Bian, J., Zhou, L., Wan, X. et al. Experimental study of laser lift-off of ultra-thin polyimide film for flexible electronics. Sci. China Technol. Sci. 62, 233–242 (2019). https://doi.org/10.1007/s11431-018-9349-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9349-x