Abstract

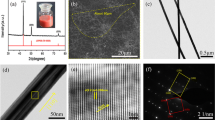

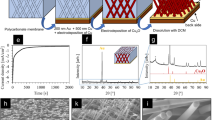

Copper (Cu) nanowires are inexpensive conducting nanomaterials intensively explored for transparent conducting electrodes and other applications. Here, Cu nanowires with approximately 40-nm diameter and a few hundreds of micrometers in length were selectively and facilely synthesized by a tetradecylamine (TDA)-assisted hydrothermal method. The Cu nanowires were highly flexible and were not oxidized by oxygen in air because of TDA’s effective coating on the Cu nanowires, which was confirmed by SEM observation and FT-IR spectrum. Moreover, the Cu nanowires tended to self-assemble into close-packed bundles due to hydrophobic–hydrophobic interactions between alkyl chains of TDA. The roles of the reagents in the preparation process were investigated systematically. First, a proper concentration of TDA was essential to high-quality Cu nanowires and TDA had two effects: (1) TDA molecules could coordinate with copper cations to form Cu(II)-complex, which was then reduced to Cu by glucose; (2) In the growth mechanism of Cu nanowires, the newly formed side surfaces, {100} facets, was stabilized through chemical interactions with the nitrogen atom of TDA (capping agent). With regards to Cu source, when using cupric chloride, cupric nitride, cupric acetate, and cupric bromide, Cu nanomaterials with a variety of shapes such as nanowires, nanoparticles, hollow spheres, and nanoflakes could be obtained. Among these Cu sources, cupric chloride was a proper selection for the preparation of Cu nanowires. About reductant agents, glucose could be replaced by other reductant agents such as VC. The UV–Vis absorption spectrum showed that the Cu nanowires had an absorption peak at 580 nm and a slightly higher transmittance in the visible region. These Cu nanowires were expected to find widespread use in the applications such as fabrication of transparent electrodes for flexible electronics and display devices. This TDA-assisted hydrothermal method could be expanded to preparation of different types of Cu nanostructures.

Similar content being viewed by others

References

Xu WH, Zhang YX, Guo Z, Chen X, Liu JH, Huang XJ, Yu SH (2012) Small 8:53–58. doi:10.1002/smll.201101445

Hu LB, Kim HS, Lee JY, Peumans P, Cui Y (2010) ACS Nano 4:2955–2963. doi:10.1021/nn1005232

Xiao GZ, Tao Y, Lu JP, Zhang ZY, Kingston D (2011) J Mater Sci 10:3399. doi:10.1007/s10853-010-5228-3

Lipscomb LD, Vichchulada P, Bhatt NP, Zhang QH, Lay MD (2011) J Mater Sci 46:6812. doi:10.1007/s10854-011-0367-0

Kumar A, Zhou CW (2010) ACS Nano 4:11–14. doi:10.1021/nn901903b

Rathmell AR, Wiley BJ (2011) Adv Mater 23:4798–4803. doi:10.1002/adma.201102284

Choi H, Park S (2004) J Am Chem Soc 126:6248–6249. doi:10.1021/ja049217

Malandrino G, Finocchiaro ST, Nigro RL, Bongiorno C, Spinella C, Fragalà IL (2004) Chem Mater 16:5559–5561. doi:10.1021/cm048685f

Shimotsuma Y, Yuasa T, Homma H, Sakakura M, Nakao A, Miura K, Hirao K, Kawasaki M, Qiu J, Kazansky PG (2007) Chem Mater 19:1206–1208. doi:10.1021/cm062592b

Molars MET, Dobrev VBDD, Neumann R, Scholz R, Schuchert IU, Vetter J (2001) Adv Mater 13:63–65. doi:0935-9648/01/0101-0064

Gao T, Meng GW, Wang YW, Sun SH, Zhang LD (2001) J Phys: Condens Mater 14:355–363. doi:10.1088/0953-8984/14/3/306

Zhao YX, Zhang Y, Li YP, Yan ZF (2012) New J Chem 36:130–138. doi:10.1039/C1NJ20800D

Chang Y, Lye ML, Zeng HC (2005) Langmuir 21:3746–3748. doi:10.1021/la050220w

Jin MS, He GN, Zhang H, Zeng J, Xie ZX, Xia YN (2011) Angew Chem Int Ed 50:10560–10564. doi:10.1002/anie.201105539

Liu ZP, Yang Y, Liang JB, Hu ZK, Li S, Peng S, Qian YT (2003) J Phys Chem B 107:12658–12661. doi:10.1021/jp036023s

Zhang XJ, Zhang DG, Ni XM, Zheng HG (2006) Solid State Commun 139:412–414. doi:10.1016/j.ssc.2006.06.042

Pradel KC, Sohn K, Huang JX (2011) Angew Chem Int Ed 50:3412–3416. doi:10.1002/anie.201100087

Ye EY, Zhang SY, Liu SH, Han MY (2011) Chem Eur J 17:3074–3077. doi:10.1002/chem.201002987

Dempsey DG, Kleinmanm L (1977) Phys Rev B 16:5356–5366. doi:10.1103/PhysRevB.63.224106

Gilles RB, Lennox RB (2010) J Am Chem Soc 132:6657–6659. doi:10.1021/ja101579v

Lu QY, Gao F, Zhao DY (2002) Nano Lett 2:725–728. doi:10.1021/nl025551x

Wang HS, Qian XL, Chen JG, Ding SY (2005) Colloid Surf A 256:111–115. doi:10.1016/j.colsurfa.2004.12.058

Gai PL, Harmer MA (2002) Nano Lett 2:771–774. doi:10.1021/nl0202556

Venables JA (2000) Introduction to surface and thin film processes. Cambridge University Press, Cambridge

Wiley B, Sun YG, Mayers B, Xia YN (2005) Chem Eur J 11:454–463. doi:10.1002/chem.200400927

Mohl M, Pusztai P, Kukovecz A, Konya Z (2010) Langmuir 26:16496–16502. doi:10.1021/la101385e

Jin MS, Zhang H, Wang JG, Zhong XL, Lu N, Li ZY, Xie ZX, Kim MJ, Xia YN (2012) ACS Nano 6:2566–2573. doi:10.1021/nn2050278

Acknowledgements

This work is financially supported by the National Natural Science Foundation Program of China (50802006) and (51172017), Natural Science Foundation Program of Beijing (2102028), Fok Ying Tung Education Foundation Fund for Young College Teachers (122016), and the Fundamental Research Funds for the Central Universities (FRF-TP-11-004A).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, B., Qin, M., Zhang, Z. et al. The influence of reagents on the preparation of Cu nanowires by tetradecylamine-assisted hydrothermal method. J Mater Sci 48, 4073–4080 (2013). https://doi.org/10.1007/s10853-013-7219-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7219-7