Abstract

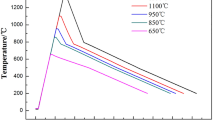

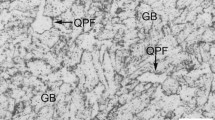

In this investigation, thermal simulated specimens were used to investigate the effect of second peak temperature during in-service welding on characteristic fracture energy and microstructure feature of the subcritically (SC), intercritically (IC), supercritically (SCR), and unaltered (UA) reheated coarse grain heat-affected zones (CGHAZs). The API X70 high-strength pipeline micro-alloyed steel was subjected to processing during in-service welding by applying double thermal cycle shielded metal arc welding process with heat input of 9.3 kJ/cm and thermal cycles to simulate microstructure of reheated CGHAZs. This consisted of first thermal cycle with a peak temperature of 1350 °C, then reheating to different second peak temperatures of 600, 800, 1000, and 1200 °C with a constant cooling rate of 60 °C/s. Toughness of the simulated reheated CGHAZs were assessed using Charpy impact testing at −20 °C, and the corresponding fractographs, optical micrographs, and electron micrographs have been examined. It is found that accelerating cooling rate during in-service welding has an improving effect on the microstructure of CGHAZs. Owing to small heat-input and accelerating cooling, the grain size in reheated CGHAZs is relatively small and the brittle microphases are eliminated or minimized. The Charpy impact results show that the CGHAZ fracture energy is improved after the second thermal cycle. The SC CGHAZ showed higher absorbed impact energy and the IR CGHAZ had less absorbed energy, but the phenomenon of embrittlement in IR CGHAZ is not serious. Therefore, it can be concluded that the fracture energy of CGHAZ and IR CGHAZ can be improved by accelerating cooling with appropriate cooling rate.

Similar content being viewed by others

References

Shin SY, Hwang B, Lee S, Kim NJ, Ahn SS (2007) Mater Sci Eng A 458(1–2):281. doi:10.1016/j.msea.2006.12.097

Corbett K, Bowen R, Petersen C (2004) Int J Offshore Polar Eng 14(1):105

Koo JY, Luton MJ, Bangaru NV, Petkovic RA, Fairchild DP, Petersen CW, Asahi H, Hara T, Terada Y, Sugiyama M, Tamehiro H, Komizo Y, Okaguchi S, Hamada M, Yamamoto A, Takeuchi I (2004) Int J Offshore Polar Eng 14(1):10

Xiao F-R, Liao B, Shan Y-Y, Qiao G-Y, Zhong Y, Zhang C, Yang K (2006) Mater Sci Eng A 431(1–2):41. doi:10.1016/j.msea.2006.05.029

Lee CH, Bhadeshia HKD H, Lee HC (2003) Mater Sci Eng A 360(1–2):249. doi:10.1016/s0921-5093(03)00477-5

Pan T, Yang ZG, Zhang C, Bai BZ, Fang HS (2006) Mater Sci Eng A 438–440:1128. doi:10.1016/j.msea.2006.02.078

Ju J-B, Lee J-S, Jang J-i (2007) Mater Lett 61(29):5178. doi:10.1016/j.matlet.2007.04.007

Zhou Z, Liu S (1998) Acta Metall Sin-Engl Lett 11(2):87

Lee S, Kim B, Kwon D (1992) Metall Mater Trans A 23(10):2803. doi:10.1007/bf02651759

Li Y, Crowther D, Green M, Mitchell P, Baker T (2001) Isij Int 41(1):46

Bayraktar E, Kaplan D (2004) J Mater Process Tech 153–154:87. doi:10.1016/j.jmatprotec.2004.04.021

Jang J-i, Ju J-B, Lee B-W, Kwon D, Kim W-S (2003) Mater Sci Eng A 340(1–2):68. doi:10.1016/s0921-5093(02)00190-9

Suzuki S, Kamo T, Komizo Y (2009) Weld Int 23(6):397

Yang Z, Sista S, Elmer JW, DebRoy T (2000) Acta Mater 48(20):4813. doi:10.1016/s1359-6454(00)00279-2

Sun W, Wang G, Zhang J, Xia D, Sun H (2009) J Mater Sci Technol 25(06):857

Qiu H, Mori H, Enoki M, Kishi T (2000) Metall Mater Trans A 31(11):2785

Andrews KW (1965) J Iron Steel Inst 203:721

John P (2002) In: Leigh F (ed) X80 pipeline cost workshop, Hobart

Acknowledgements

The research was partially supported by the National Natural Science Foundation of China (51074174) and the Innovation Fund for Doctors of China University of Petroleum (B2009-13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Wang, Y. & Chen, Y. Influence of peak temperature during in-service welding of API X70 pipeline steels on microstructure and fracture energy of the reheated coarse grain heat-affected zones. J Mater Sci 46, 6424–6431 (2011). https://doi.org/10.1007/s10853-011-5592-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5592-7