Abstract

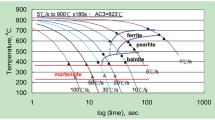

Die design is one of the key technologies for hot stamping technology, and the quality of the forming part is influenced by the structure design of the cooling system parameters. Cooling pipe size, distance between cooling pipes, and depth from cooling pipe to die surface are the most important structure parameters, and the final microstructure and property of the forming parts are influenced directly by these structural parameters. In this article, the simplified model of hot stamping die was established, and the hot stamping die cooling structural parameters were analyzed by heat transfer theory. The mathematical model of the structure parameters was set up and verified by simulation and experiment. It was shown that the mathematical model of the hot stamping die cooling structural parameters met the cooling requirements; the hot stamping parts achieved the need of the martensite structure.

Similar content being viewed by others

References

Naderi M, Uthaisangsuk V, Prahl U, Bleck W (2008) A numerical and experimental investigation into hot stamping of boron alloyed heat treated steels. Steel Res Int 79(2):77–84

Engels H, Schalmin O, Muller-Bollenhagen C (2006) Controlling and monitoring the hot stamping process of boron-alloyed heat treated steels. The International Conference “New Development in Sheet Metal Forming Technology,” Stuttgart, Germany, pp.135–150

Geiger M, Merklein M, Hoff C (2005) Basic investigation on the hot stamping steel 22MnB5. Proceedings of the Sheet Metal 2005 Conference, pp. 795–802

Hein P, Wilsius J (2008) Status and innovation trends in hot stamping of USIBOR1500P. Steel Res Int 79(2):85–91

Lin JP, Sun GH, Zhu QH, Hu Q, Wang LY, Tian HB (2009) Research on analytical model of blank temperature prediction for hot stamping of ultra high strength steels. Forging Stamping Technol 34(1):20–23

Li HP, Zhao GQ, Zhang L, He LF (2010) The development status of hot stamping and quenching of ultra high-strength steel. J Shandong Univ (Eng Sci) 40(3):69–74

Xu WL, Ai J, Luo AH, Guan SR (2009) Introduction of sheet metal hot-forming. J Plasticity Eng 16(4):39–43

Liu HS, Lei CX, Xing ZW (2013) Cooling system of hot stamping of quenchable steel BR1500HS: optimization and manufacturing methods. Int J Adv Manuf Technol. doi:10.1007/s00170-013-4996-8

Yang SM, Tao WQ (2006) Heat transfer (fourth edition). Higher Education Press, Beijing, pp.77, 78, 248

Jiang C, Shan ZD, Zhuang BL, Zhang ML, Xu Y (2012) Hot stamping die design for vehicle door beams using ultra-high strength steel. Int J Precis Eng Manuf 13(7):1101–1106

Shan ZD, Zhang ML, Jiang C, Xu Y, Rong WJ (2010) Basic study on die cooling system of hot stamping process. Proceedings of the International Conference on Advanced Technology of Design and Manufacture. Beijing: IET, 65–68

Xu Y (2011) Study of hot stamping die technology for ultra high strength steel door beam. Dissertation, China Academy of Machinery Science & Technology, Beijing

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ying, X., Zhong-de, S. Design parameter investigation of cooling systems for UHSS hot stamping dies. Int J Adv Manuf Technol 70, 257–262 (2014). https://doi.org/10.1007/s00170-013-5272-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5272-7