Abstract

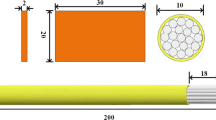

The ultrasonic wire bonding (UWB) process has been examined using transmission electron microscopy (TEM) and standard wire pull testing techniques. Al-0.5 wt.% Mg wires 75 μm in diameter were bonded to pure and alloyed Al substrates. The bonding parameters, surface roughness, and surface contamination levels were variables in the experiments. Cross-section TEM specimens were made from these samples. TEM analysis was conducted on the wire, wire/substrate interface and substrate. Pull tests showed that for the Al substrates the surface roughness or the presence of contamination did not effect the bond strength, whereas for contaminated stainless steel substrates, a three μm surface finish resulted in the highest bond pull strength. The TEM observations revealed features such as low-angle grain boundaries, dislocation loops and the absence of a high dislocation density, indicating that the wire and substrate were dynamically annealed during bonding. Based on the width of a zone near a grain boundary in the wire which was depleted of dislocation loops, it was estimated that local heating equivalent to a temperature of 250° C for 90 msec was achieved in the wire during bonding. No evidence was found for melting along the bond interface, indicating that UWB is a solid-state process. Based on the TEM observationsof the bond interface and the pull tests, it is concluded that the ultrasonic vibrations clean the surfaces to be joined to the extent that a good bond can be obtained by intimate metal-metal contact in the clean areas.

Similar content being viewed by others

References

K. C. Joshi,Welding Journal 50, 840 (1971).

G. G. Harman and K. O. Leedy,10th Annu. Proc. of Reliability Phys. Symp., pp. 49–56 (1972).

G. G. Harman and J. Albers, IEEE Trans. on Parts, Hybrids and PackagingPHP-13, 406 (1977).

V. H. Winchell, 14thAnnu. Proc. Reliability Phys. Symp., pp. 98–107 (1976).

V. H. Winchell and H. M. Berg, IEEE Trans. on Components, Hybrids, and Manufact. Techn.CHMT-1, 211 (1978).

H. Kreye, Welding Journal 154s (1975).

J. E. Krzanowski, Proc. 39th Electron. Comp. Conf., Houston, TX, p. 451–456 (1989); also to be published in the March issue of the IEEE Trans, on CHMT.

B. Langenecker, IEEE Trans. Sonics and UltrasonicsSU-13, 1 (1966).

E. A. Brandes, Smithells Metals Reference Book—6th Ed., London: Butterworths & Co. LTD (1983) p. 55.

V. P. Severdenko, V. V. Klubovich and A. V. Stepanenko, in Ultrasonic Rolling and Wire Drawing of Metals, Consultants Bureau, New York (1972) pp. 43–50.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Krzanowski, J.E., Murdeshwar, N. Deformation and bonding processes in aluminum ultrasonic wire wedge bonding. J. Electron. Mater. 19, 919–928 (1990). https://doi.org/10.1007/BF02652917

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02652917