Conclusions

-

1.

A. flow-type apparatus has been developed for the investigation or processes of heat treatment of powered materials in moving vibrating beds.

-

2.

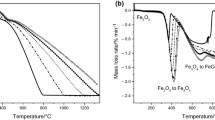

A study was made of the final reduction of residual oxides in an iron powder and milled sponge iron and hydrogen. It was established that: a) at a temperature above 700° C a high-quality product (total Fe≃99.0%) can be obtained, with apparatus throughputs of 45 and 30 g/min, respectively, by annealing PZh5M iron powder for 4–5 min and milled sponge iron 8–10 min, b) the final reduction of residual oxides is controlled by diffusion mass tranport.

Similar content being viewed by others

Literature cited

B.I. Bondarenko, “Use of direct iron production units in large-tonnage iron powder manufacture,” Poroshk. Metall., No. 2, 68–71 (1977).

G. A. Meerson, “Changes needed in the manufacturing technology of unalloyed iron powders,” Poroshk. Metall., No. 5, 20–28 (1974).

I. D. Radomysel'skii, “Technological processes for the production of iron and alloy powders used in the USSR,” in: Problems in Present-Day Powder Metallurgy [in Russian], Naukova Dumka, Kiev (1970), pp. 21–37.

L. V. Krasnichenko, V. I. Litvinenko, V. D. Kishko, and V. G. Lyul'ko, “Furnace for annealing metal powders,” Inventors' Certificate No. 545847; Byull. Izobret., No. 5 (1977).

L. V. Krasnichenko, V. G. Lyul'ko, V. I. Litvinenko, et al., “Furnace for the production of metal powders,” Inventors' Certificate No. 603823; Byull. Izobret., No. 15 (1978).

V. A. Chlenov and N. V. Mikhailov, The Vibrating Fluid Bed [in Russian], Nauka, Moscow (1972).

V. D. Karmazin, Vibrating Bed Technology and Applications [in Russian], Naukova Dumka, Kiev (1977).

E. A. Kapustin, A. S. Khadzhinov, et al., “Some features of the kinetics and mechanism of reduction of iron oxides by natural gas,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 1, 5–8 (1978).

E, A. Kapustin, V. A. Maslov, A. M. Kulakov, et al., “Oxygen in sponge iron and iron powders,” Poroshk. Metall., No. 6, 17–21 (1974).

S. T. Rostovtsev, Theory of Metallurgical Processes [in Russian], Metallurgizdat, Moscow (1956).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 7(199), pp. 1–5, July, 1979.

Rights and permissions

About this article

Cite this article

Lyul'ko, V.G., Krasnichenko, L.V., Kishko, V.D. et al. Final reduction annealing of iron powder in a vibrating bed. Powder Metall Met Ceram 18, 423–426 (1979). https://doi.org/10.1007/BF00797241

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00797241