Abstract

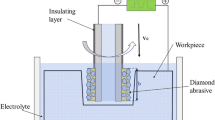

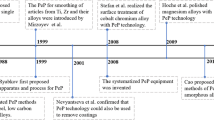

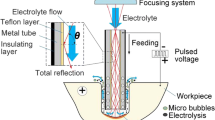

Because of structural simplicity, low production costs and small atomizing droplets, ultrasonic atomization used in aerospace, medical, energy saving and other fields. With the increasing need to increase improve the atomization efficiency, Researchers have made a lot of efforts. However, the micro-tapered hole group on atomizer has not been deeply studied. In this study, the electrolytic polishing processing is proposed to improve the quality of the micro-tapered holes. First, a mathematical relation of atomization amount and polishing time was established. Second, the relevant parameter were measured using a microscope. Lastly, the mathematical relation was determined and revised through an atomization amount experiment. The experimental results show that when the polishing time is 4 min, the atomization amount reaches the maximum of 4.53 ml/min, which is much higher than that of the untreated atomizer. This study demonstrates that polishing can effectively remove burr in the process of hole machining, which will further improve the atomization efficiency of atomizers.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Guerra-Bravo E, Lee H-J, Baltazar A, Loh KJ (2021) Vibration analysis of a piezoelectric ultrasonic atomizer to control atomization rate. Appl Sci 11:8350

Jianhui Z, Qiufeng Y, Wanting S (2020) Advances in piezoelectric atomizers. Trans Nanjing Univ Aeronautics Astronautics

Pritchard JN, Hatley RH, Denyer J, Hollen DV (2018) Mesh nebulizers have become the first choice for new nebulized pharmaceutical drug developments. Therapeutic Deliv 9:121–136

Maehara N, Ueha S, Mori E (1986) Influence of the vibrating system of a multipinhole-plate ultrasonic nebulizer on its performance. Rev Sci Instrum 57:2870–2876

Toda K, Akimura Y (1994) An ultrasonic atomizing device using coupled-mode vibration. Rev Sci Instrum 65:3276–3278

Toda K, Ishii JIJ (1995) Operation performance of self-oscillation ultrasonic vibrating device for liquid atomization. Jpn J Appl Phys 34:5332

Lu C, Fu C, Yang J, Chen C, Cheng C (2006) 4A-3 traveling wave driven micro-dispenser for CPU cooling application. In: Proceedings of the 2006 IEEE ultrasonics symposium, pp 54–57

Shen S-C, Wang Y-J, Chen Y-Y (2008) Design and fabrication of medical micro-nebulizer. Sens Actuators A 144:135–143

Maehara N, Ueha S, Mori E (1987) Optimum design procedure for multi-pinhole-plate ultrasonic atomizer. Jpn J Appl Phys 26:215

Lam KH, Chan H, Luo H, Yin Q, Yin Z (2005) Piezoelectrically actuated ejector using PMN–PT single crystal. Sens Actuators A 121:197–202

Dupuis E, Momen AM, Patel VK, Shahab S (2018) Multiphysics modeling of mesh piezoelectric atomizers. In: Proceedings of the active and passive smart structures and integrated systems XII, pp 429–437

Sar G, Aydn YN, Bilekli MG, Gl MB (2021) Dynamics of liquid drop on a vibrating micro-perforated plate. Zeitschrift fur Naturforschung A 76

Sharma P, Jackson N (2022) Vibration analysis of MEMS vibrating mesh atomizer. J Micromechanics Microengineering 32

Yan Q, Sun W, Zhang J (2020) Study on the influencing factors of the atomization rate in a piezoceramic vibrating mesh atomizer. Appl Sci 10:2422

Zhang L, Tong H, Li Y (2015) Precision machining of micro tool electrodes in micro EDM for drilling array micro holes. Precis Eng 39:100–106

Akiyoshi O (2004)Flow direction of piezoelectric pump with nozzle/diffuser-elements. Chin J Mech Eng 107–109

Han W, Fang F (2019) Fundamental aspects and recent developments in electropolishing. Int J Mach Tools Manuf 139:1–23

Huang Y, Wang C, Ding F, Yang Y, Li N (2021) Principle, process, and application of metal plasma electrolytic polishing: a review. Int J Adv Manuf Technol

Han W, Fang F (2019) Electropolishing of 316L Stainless Steel using sulfuric acid-free electrolyte. J Manuf Sci Eng 141

Zhou C, Su H, Qian N, Zhang Z, Xu J (2022) Characteristics and function of vapour gaseous envelope fluctuation in plasma electrolytic polishing. Int J Adv Manuf Technol 119:7815–7825

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Huang, WQ., Liang, JL., Zhang, JH., Zhang, F. (2024). Optimization of Ultrasonic Atomization by Electrolytic Polishing. In: Wang, W., Liu, X., Na, Z., Zhang, B. (eds) Communications, Signal Processing, and Systems. CSPS 2023. Lecture Notes in Electrical Engineering, vol 1032. Springer, Singapore. https://doi.org/10.1007/978-981-99-7505-1_28

Download citation

DOI: https://doi.org/10.1007/978-981-99-7505-1_28

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7539-6

Online ISBN: 978-981-99-7505-1

eBook Packages: EngineeringEngineering (R0)