Abstract

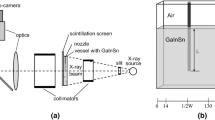

A numerical simulation was performed in Fluent® to optimize bubble stirring in a melting pot. The study focused mainly on optimization of the gas injection positions and sparging rates. Coalescence of bubble trains was studied in detail through a numerical analysis implementing the VOF method as well as an innovative method developed in the laboratory. This numerical study is also based on hydraulic similarity tests with a mock-up and oil bath. This article describes the numerical model of this complex phenomenon and quantifies the overall improvement in oil bath flow within the oil volume concerned.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Geoffroy, O., Rouch, H., Sauvage, E. & Bonnetier, A. (2012). Mixing process by gas bubbling simulation.7th Open FOAM workshop, Darmstadtiun, Darmstadt, Germany.

ANSYS FLUENT 12.0/12.1 Documentation.

Akhtar, A., Pareek, V., & Tadé, M. (2007). CFD simulations for continuous flow of bubbles through gas-liquid columns: Application of VOF method. Chemical Product and Process Modeling, 2(1), 1–19.

Snabre, P., & Magnifotcham, F. (1998). Formation and rise of a bubble stream in a viscous liquid. The European Physical Journal, 4(3), 369–377.

Snabre, P. & Magnifotcham (1998). Recirculation flow induced by a bubble stream rising in a viscous liquid. The European Physical Journal, 4(3), 379–386.

Jamialahmadi, M., Zehtaban, M., Muller-Streinhagen, H., Sarrafi, A. & Smith, J. (2001). Study of bubble formation under constant flow conditions. Chemical Engineering Research and Design, 79(5), 523–532.

Kulkarni, A. A., & Joshi, J. B. (2005). Bubble formation and bubble rise velocity in gas-liquid systems: A review. Industrial and Engineering Chemistry Research, 44(16), 5873–5931.

Miyahara, T., Takahashi, T. (1985). Drag coefficient of single bubble rising through a quiescent liquid. Int Chemical Engineering, 25(1).

Loth, E. (2008). Quasi-steady shape and drag of deformable bubbles and drops. International Journal of Multiphase Flow, 34(6), 523–546.

Bonometti, T. (2005). Développement d’une méthode de simulation d’écoulement à bulles et à gouttes. PhD thesis, I.N.P. Toulouse.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Gautheron, D. et al. (2014). Bubble-Stirred Melts in Vitrification. In: Gourbesville, P., Cunge, J., Caignaert, G. (eds) Advances in Hydroinformatics. Springer Hydrogeology. Springer, Singapore. https://doi.org/10.1007/978-981-4451-42-0_36

Download citation

DOI: https://doi.org/10.1007/978-981-4451-42-0_36

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-4451-41-3

Online ISBN: 978-981-4451-42-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)