Abstract

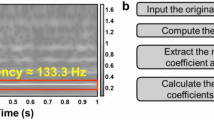

Real-time monitoring of tool health is of great importance for the production of mechanical equipment. The sensor signals that monitor the health of the tool are indicative of the tool wear. The sensor signals collected are typically acoustic signals, force signals, vibration signals and spindle power signals. The acquired signals are first pre-processed and then feature decomposed to extract time domain frequency domain and time-frequency domain features. Multiple sensor signals can effectively increase the accuracy of monitoring, but can produce a large amount of redundant information. It is particularly important to match the number of sensor signals and feature extraction methods to complement each other and combine them organically.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Nie, P., Ma, Y., Zhang, K.F., et al.: Research status and development of tool wear monitoring technology. Tool Eng. 55(06), 3–12 (2021)

Zhou, H., Zhang, Z.N.: Feature transfer-based approach for tool wear monitoring of face milling. Tribology 121, 723–716 (2021). https://doi.org/10.16078/j.tribology.2021158

Vetrichelvan, G., Sundaram, S., Kumaran, S., et al.: An investigation of tool wear using acoustic emission and genetic algorithm. J. Vib. Control 21(15), 3061–3066 (2015)

Wu, Y.; Hong, G.S.; Wong, W.S.: Prognosis of the probability of failure in tool condition monitoring application-a time series-based approach. Int. J. Adv. Manuf. Technol. 76(1), 513–521 (2018)

Yu, J., Liang, S., Tang, D., Liu, H.: A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. Int. J. Adv. Manuf. Technol. 91(1–4), 201–211 (2016). https://doi.org/10.1007/s00170-016-9711-0

Tian, Y., Wang, W.H.: A method for tool condition monitoring based on spindle power. J. Tianjin Univ. (Sci. Technol.) 54(11), 1179–1186 (2021)

Zhang, C.B.: Tool Wear and Life Prediction Based on Deep Learning and System Development. South China University of technology. Guangzhou (2020)

Luo, H., Zhang, D.H., Luo, M.: Tool wear and remaining useful estimation of difficult-to-machine aerospace alloys: a review. China Mech. Eng. 32(22), 2647–2666 (2021)

Guo, J.C., Li, A.H.: Advances in monitoring technology of tool wear condition. Tool Eng. 53(05), 3–13 (2019)

Li, W.L.: Research on Key Technologies of Tool Condition Monitoring and Prediction in Turning and Milling. Southwest Jiao tong University, Chengdu (2013)

Wang, J., Wang, P., Gao, R.X.: Enhanced particle filter for tool wear prediction. J. Manuf. Syst. 36, 35–45 (2015)

Yang, W.A., Zhou, Q., Tsui, K.L.: Differential evolution-based feature selection and parameter optimization for extreme learning machine in tool wear estimation. Int. J. Prod. Res. 54(15), 4703–4721 (2016)

Javed, K., Gouriveau, R., Zerhouni, N., Nectoux, P.: Enabling health monitoring approach based on vibration data for accurate prognostics. IEEE Trans. Industr. Electron. 62(1), 647–656 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Lu, X.X., Wang, C., Liu, C. (2023). Research on the Processing Method of Tool Sensor Signal. In: Wang, Y., Yu, T., Wang, K. (eds) Advanced Manufacturing and Automation XII. IWAMA 2022. Lecture Notes in Electrical Engineering, vol 994. Springer, Singapore. https://doi.org/10.1007/978-981-19-9338-1_18

Download citation

DOI: https://doi.org/10.1007/978-981-19-9338-1_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9337-4

Online ISBN: 978-981-19-9338-1

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)