Abstract

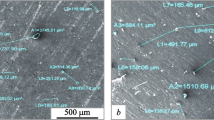

Aluminum matrix composites is aluminum matrix reinforced with metal, ceramic, or organic compound. The reinforcement is used to improve mechanical, thermal, or tribological properties of the matrix. Stir casting is an economical process to fabricate the aluminum matrix composites. Stir casting is conducted by mechanical stirring of the reinforcement particulate into metal liquid. The metal matrix composites resulted from the stir casting is affected by a homogeneous distribution of the reinforcement. The objective of this research is to investigate the effect of reinforcement preheating that has been on electroless coating on hardness and micro structure of aluminum metal matrix composite. This study used aluminum series 6061 as a matrix and Al2O3 as reinforcement. The temperatures of reinforcement preheating were varied at 200 ℃, 300 ℃, 400 ℃, and 500 ℃. Stirring temperature parameters of 700 ℃ ± 10 ℃, melting temperature of 750 ℃ ± 10 ℃, pouring temperature of 750 ℃ ± 10 ℃, stirring times of five minutes, and stirring speed of 550 rpm. The results showed that the preheating Al2O3 reinforcement can reduce segregation. As the preheating temperature increases, reinforcement segregation decreases, resulting in an increase in the wettability of Al2O3 reinforcement in aluminum.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

James J, Ganesan M, Santhamoorthy P, Kuppan P (2018) Development of Hybrid Aluminum Metal Matrix Composite and Study of Property. Material Today Proceedings 5:13048–13054

Kevin KP, Sijo MT (2015) Effect of Stirrer Parameter of Stir Casting on Mechanical Properties of Aluminum Silicon Carbide Composite. International Journal of Modern Engineering Research (IJMER) 5:43–49

Mohit KS, Sahu RK (2018) Fabrication of Aluminum Matrix Composites by Stir Casting Technique and Stirring Process Parameters Optimization. Additional Information is Avaible at the end of the Chapter 7:112–126

Mahesh VP, Nair PS, Rajan TPD, Hubli RC (2011) Processing of Surface-Treated Boron Carbide-Reinforced Aluminum Matrix Composites by Liquid-Metal Stir-Casting Technique. J Compos Mater 45(23):2371–2378

Mithun BR, Madeva N, Auradi V, Bharath V (2017) Microstructure and Mechanical Properties of Cu-Coated A2O3 Particulate Reinforced 6061 Al Metal Matrix Composite. Material Today Proceeding 4:11015–11022

Juhua L, Zhengzhi Z, Di T, Ye N, Shufeng Y, Weining L (2017) Microstructural Homogeneity and Mechanical Property of Medium Manganese Steel with Mn Segregation Banding by Alternating Lath Matrix. Mater Sci Eng, A 711:175–181

Guoyun L, Hui X, Simeng L, Cunshan W, Qiang Z, Lijun S (2019) Quasi-Continuous-Wave Laser Surface Melting of Aluminium Alloy: Precipitate Morphology, Solute Segregation and Corrosion Resistance. Corros Sci 152:109–119

Phanibhushana MV, Chandrappa CN, Niranjan HB (2017) Study of Wear Characteristics of Hematite Reinforced Aluminum Metal Matrix Composites. Material Today Proceedings 5:3484–3493

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Setia, I., Surojo, E., Ariawan, D. (2020). Effect of Reinforcement (Al2O3) Preheating on Hardness and Microstructure of Aluminum Matrix Composite. In: Sabino, U., Imaduddin, F., Prabowo, A. (eds) Proceedings of the 6th International Conference and Exhibition on Sustainable Energy and Advanced Materials. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-4481-1_56

Download citation

DOI: https://doi.org/10.1007/978-981-15-4481-1_56

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4480-4

Online ISBN: 978-981-15-4481-1

eBook Packages: EngineeringEngineering (R0)