Abstract

Electrolytic dehumidification with polymer electrolyte membrane (PEM) is a compact and effective independent humidity control method for refrigerators. To explore the performance of PEM-based dehumidification under sub-zero conditions, experiments were conducted at low temperatures of −10–0 °C. Results showed that this device could operate stably at temperatures above −8.5 °C. The moisture removal rate was 0.05–0.08 × 10−9 g/s, and the energy efficiency was 0.64–0.68 × 10−2 g/(J m2), respectively. It has also been found that the moisture removal rate and energy efficiency decreased with the decrease of absolute humidity in the air. Furthermore, the performance under sub-zero conditions was relatively low, which the dehumidification rate at −8.5 °C was only 1/6 of that at 25 °C. The possible reason is that water inside the PEM may be frost, hindering the proton transmission below 0 °C. Besides, the electrical conductivity also reduces due to the low temperature. This study proved that PEM-based dehumidification is a promising alternative for independent humidity control under low-temperature conditions.

Similar content being viewed by others

Keywords

- Electrolytic dehumidification

- Refrigerator

- Sub-zero environment

- Independent humidity control

- Experiments

1 Introduction

In recent years, with the improvement of quality of life, people’s storage requirements for foods become higher and higher. For example, dry goods, tea, and some precious herbs need to be stored in an area with a low RH (relative humidity) of 45% RH or less, while the storage humidity of cakes or breads should be kept at about 60% RH. Thus, many companies have developed refrigerators with classified storage. These refrigerators perform well in the temperature control, but not good enough in the classified humidity control. Many dehumidification technologies, such as condensation ones, cannot operate under sub-zero temperatures. Desiccant absorption could be operating at low temperature, but it usually has a big volume. As the humidity control in current refrigerators is usually achieved by changing the operating strategies of evaporators, compressors, and fans [1], the energy efficiency was low and the pipeline was complicated [2]. Furthermore, the space inside the refrigerators is very limited, which increases the difficulty of installing dehumidification equipment.

Electrolytic dehumidification with electrolyte membrane is an innovative independent humidity control technology and driven by low voltage electricity. In 2000, Iwahara et al. first proposed the use of solid electrolyte material SrCeO ceramics for electrical dehumidification and verified its feasibility under DC voltage [3]. In 2005, it was found by Onda et al. that the electroosmotic effect could not be ignored [4]. In 2009, the possibility of dehumidification by electricity at room temperature (20–40 °C) was verified [5]. The V-I characteristics were tested, the influence of air temperature on system performance was analyzed, and an empirical formula was proposed by Sakuma et al. [6]. Previous research of our research group found that under 3 V electric field, the air outlet humidity could be reduced from 90 to 30%. And the dehumidification energy efficiency was 2.0–3.0 × 10−2 g/(J m2), which was competitive with other dehumidification methods [7].

Previous research found that as the moisture transport is driven by the electric field rather than the difference of temperature or water vapor partial pressure, this system has the potential to be operated efficiently under low-temperature conditions. In this paper, the operation performance of PEM-based electrolytic dehumidification was investigated experimentally, under a sub-zero environment with the temperature range of −10–0 °C. The dehumidification device was constructed by a PEM, a porous electrode with a catalytic layer and a diffusion layer on both sides, and two outermost gas passages. During experiments, the voltage and air humidity were 3 V and 55–65% RH, respectively, and the flow rate was 1.9 × 10−2 g/s. Nafion 117 was used as an electrolyte membrane. The humidity, temperature, and current were recorded. This study investigated the performance of the device operation under low-temperature conditions(<0 °C) and proofed its feasibility in the application of refrigerators.

2 Methods

In this study, a PEM-based electrolytic experimental system was developed. The PEM component was composed of electrolytic membrane, porous Pt cathode, and IrO2 anode with catalytic layers composed of noble metal particles, and carbon fiber papers as diffusion layers on both sides. The gas passage, whose thickness was 2 mm, was on the outermost side. When a DC voltage was applied, the reactions was shown in Eqs. (1) and (2) occurred. At the anode side, water vapor in the air was decomposed on the catalytic layer, producing H+ protons. The H+ protons were driven toward the cathode side through the proton exchange membrane and reacted with oxygen to form water at the cathode side. At the same time, some water molecules were carried from the anode side to the cathode side by H+ protons. This is called the electroosmotic effect. Then the water at cathode side would be taken away by the sweep gas. Since the humidity at the cathode side was greater than that of anode side, a negative concentration gradient was formed, which caused some moisture moving back toward the anode.

In order to study the dehumidification performance under low-temperature conditions, the whole system with the measurement devices was placed into a constant temperature and humidity chamber. The temperature and air humidity inside could be set. Temperature and humidity setting error was ±1 °C and ±3% RH, respectively. Four 100-mL-three-necked flasks with temperature and humidity sensors were used to record the temperature and humidity. Temperature and humidity recording error were ±0.5 °C and ±3% RH at 25 °C, respectively. Several microporous flowmeters were placed at the anode inlet and cathode inlet to record the gas flow rate. The voltage was applied by a DC power, and the current was recorded by a multimeter, with the measurement error of ±2 mV and ±1 mA, respectively. The measurement error of energy efficiency is ±2.8 × 10−2 mg/(J m2). The data were collected through Agilent, and the schematic diagram of the experimental apparatus was shown in Fig. 1.

During the experiments, the moisture removal rate of the electrolyte membrane could be calculated by Eq. (3). The dehumidification efficiency could be calculated by Eq. (4).

where m is mass flow rate, ω is moisture content, Aarea is membrane area, P is power, A is anode, η is energy efficiency, and a is air.

Experimental procedures are as follows. (a) The air pump was opened for 1 h before the experiment. (b) The temperature of the chamber was set to 0 °C. (c) After the temperature was stable, the DC power was turned on. The power supply was set to 3 V. (d) After the device reached a steady state, the operational data were recorded by the Agilent data logger every 5 s. (e) Every test was conducted for about 20 min. Then reset the temperature and start the steps from the beginning. The experimental conditions were shown in Table 1.

3 Results and Discussion

In the experiment, the temperature dropped at a rate of −5.1 °C/h from 0 to −8.5 °C and the humidity fluctuated around 60% RH. Unlike the proton exchange membrane fuel cell, which had a disadvantage that it cannot be started under low-temperature conditions due to lack of water, the PEM-based dehumidification could decompose water by applying voltage and did not require a large amount of moisture to start. So the dehumidification device could be started and stabilized under lower temperature conditions.

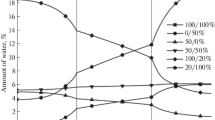

From Fig. 2, the moisture removal rate and current decreased with the decrease of temperature. When the temperature was −0.8 °C, the current and the moisture removal rate were 0.269 A and 0.0747 × 10−4 g/s, respectively. When the temperature dropped to −4.8 °C, the current was 0.217 A, and the moisture removal rate was 0.0582 × 10−4 g/s. The moisture removal rate decreased more than the current. In addition, the decline trend of current and moisture removal rate with time was not steady. As shown in Fig. 2a, the current curve first dropped and then stabilized. After a period of stability, the curve of current would decrease and then stabilize again. Simultaneously, as shown in Fig. 2b that the curve of moisture removal rate first increased and then decreased. After this, the curve would increase and then decrease again. The possible reason was that the water storage capacity of the PEM increased with the decrease of the current. In the experiment, the current was phased down. So the water in the membrane would increase first and then decrease with the decrease of temperature.

As shown in Fig. 3a because of the change of water in PEM, the moisture removal rate decreased with the decrease of absolute humidity. It would rise first and then decrease. It also could be seen from Fig. 3b that the current curve was substantially consistent with the absolute humidity curve. Under low-temperature conditions, the absolute humidity had a greater influence on the current and the moisture removal rate. Changing the temperature actually was changing the absolute humidity.

The energy efficiency of PEM electrical dehumidification was shown in Fig. 4. In the experiment, the observed stability efficiency was 0.64–0.78 × 10−2 g/(J m2), i.e., 0.1–0.13 MJ/kg of electricity demand. It was competitive with current dehumidifiers under low temperatures. For example, Chen et al. investigated a dehumidification process with cascading desiccant wheels with sub-zero dew point and obtained the lowest electricity demand of 0.6 MJ/kg [8]. Besides, the electricity demand of electroosmotic dehumidification and thermoelectric dehumidifier was around 0.09 MJ/kg, while their performance was measured under normal temperature range about 25 °C [9].

From previous experiments, when the temperature was 25 °C, the moisture removal rate was 0.3 × 10−4 g/s. In this experiment, when the temperature was −8.5 °C, the moisture removal rate was 0.05 × 10−4 g/s. The moisture removal rate at −8.5 °C is only 1/6 of that at 25 °C. Under low-temperature conditions, especially below 0 °C, some of the water inside the PEM may frost, which would reduce the internal moisture content of the PEM. The current and dehumidification decreased with the decrease of absolute humidity, because the conductivity of the membrane would reduce due to lack of water. Furthermore, the formed frost in the diffusion layer would hinder the mass transfer during dehumidification. And the catalyst performance was also reduced because of the low temperature. But the device could run stably. Therefore, it was feasible to apply the method to the refrigerator for low-temperature-independent dehumidification.

4 Conclusion

Humidity control under low-temperature conditions has great significance in the food preservation of refrigerators. The existing dehumidification technology has many problems such as unable to operate under low temperature (<0 °C) and large device volume. As the moisture transport is driven by electric field rather than the difference of temperature or pressure, the electrolytic dehumidification has potential to be operated efficiently under sub-zero environments.

In this paper, the feasibility of PEM-based electrolytic dehumidification device was experimentally investigated under low-temperature conditions, and the factors affecting the performance were analyzed. Experiments were conducted at low temperatures of −10–0 °C. Results showed that this device could operate stably at temperatures above −8.5 °C. The moisture removal rate was 0.05–0.08 × 10−9 g/s. And the energy efficiency was 0.64–0.68 × 10−2 g/(J m2). As it showed that the moisture removal rate and energy efficiency decreased with the decrease of absolute humidity in the air. In addition, the dehumidification rate at −8.5 °C was only 1/6 of that at 25 °C, because the water inside the PEM might frost below 0 °C, which hindering the proton transmission. Furthermore, the electrical conductivity could be reduced due to the low temperature. This study showed that PEM-based dehumidification device can run stably under low-temperature conditions. Therefore, PEM-based dehumidification technology can be a promising alternative for small-scale dehumidification under low temperature for refrigerators.

Abbreviations

- m :

-

Mass flow rate

- t :

-

Temperature

- RH:

-

Relative humidity

- ⍵ :

-

Moisture content

- a :

-

Air

- A :

-

Anode

- In:

-

Inlet

- P :

-

Power

- w :

-

Water

- C :

-

Cathode

- Out:

-

Outlet

- A area :

-

Membrane area

References

Cheng, et al.: Household frost-free appliances humidity control principle and practical application (in Chinese), J. Appl. Sci. Technol. 04, 56–59 (2017)

Liu, et al.: Performance improvement in air dehumidifiers: from ideal to actual (in Chinese). Chin. Sci. Bull. 60, 2631–2639 (2015)

Iwahara, et al.: Electrochemical dehumidification using proton conducting ceramics. Solid State Ionics 136–137, 133–138 (2000)

Onda, et al.: Polymer electrolyte dehumidifying cell and its application to air condi-tioners. J. Appl. Electro-chem. 152(12), A2369–A2375 (2005)

Sakuma, et al.: Water transfer simulation of an electrolytic de-humidifier. J. Appl. Electro-chem. 39(6), 815–825 (2009)

Sakuma, et al.: Estimation of dehumidifying performance of solid polymer electrolytic dehumidifier for practical application. J. Appl. Electro-chem. 40(12), 2153–2160 (2010)

Qi, et al.: Experimental study on electrolytic dehumidifier with polymer electrolyte membrane for air-conditioning systems. Energy Procedia. 142, 1908–1913 (2017)

Chen, et al.: A dehumidification process with cascading desiccant wheels to produce air with dew point below 0 °C. Appl. Therm. Eng. 148, 78–86 (2019)

Li, Y.Y.Yan: Solid desiccant dehumidification techniques inspired from natural electroosmosis phenomena. J. Bionic Eng. 8, 90–97 (2011)

Acknowledgements

The project is supported by the National Key Research and Development Program (No. 2016YFB0901404), National Natural Science Foundation of China (51876067), the National Science Fund for Distinguished Young Scholars of Guangdong Province (2018B030306014). It is also supported by the Science and Technology Planning Project of Guangdong Province: Guangdong–Hong Kong Technology Cooperation Funding Scheme (TCFS), No.2017B050506005.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Li, T., Qi, R. (2020). A Study on Polymer Electrolyte Membrane (PEM)-Based Electrolytic Air Dehumidification for Sub-Zero Environment. In: Wang, Z., Zhu, Y., Wang, F., Wang, P., Shen, C., Liu, J. (eds) Proceedings of the 11th International Symposium on Heating, Ventilation and Air Conditioning (ISHVAC 2019). ISHVAC 2019. Environmental Science and Engineering(). Springer, Singapore. https://doi.org/10.1007/978-981-13-9524-6_21

Download citation

DOI: https://doi.org/10.1007/978-981-13-9524-6_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9523-9

Online ISBN: 978-981-13-9524-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)