Abstract

We have proposed a refractive index sensor, which is based on dual-core photonic crystal fiber (PCF) with a rectangular air-hole lattice structure. The two fiber cores of the PCF are separated by single air-hole filled with the analyte liquid and the refractive index of the analyte liquid (na) varies from 1.33 to 1.41. The highest sensitivity of 9,400 nm/RIU (Refractive index unit) can be acheived when na is 1.41 in the simulated results and lowest sensitivity is up to 5,940 nm/RIU when na is 1.33.

Similar content being viewed by others

Keywords

1 Introduction

Photonic crystal fiber (PCF) is the new kind of optical fiber having a periodic array of air holes running along the entire fiber length to create the cladding around the core of the cable. Light propagation in PCFs is much superior to conventional fiber. PCFs provide better flexibility in designing of the structure as compared with conventional optical fiber and achieve unique optical properties such as endlessly single-mode operation over a wide range of wavelength, good dispersion characteristics, high birefringence, high nonlinearity, low confinement loss, etc. [1,2,3,4,5].

However, in recent years, a rising number of PCF refractive index sensors for various applications like pressure sensor [6], refractive index sensor [7], bio and temperature sensor [8], etc. In most PCF-based sensors, only single-core photonic crystal fiber was used. Because of their flexible design and easy fabrication, dual-core PCFs have shown many advantages in the applications of optical communication and sensing [9,10,11]. Dual-core photonic crystal fiber has also shown very good performances in various applications like narrow band-pass filter [12], PCF coupler [11], polarization splitter [13], and wavelength MUX-DEMUX [14].

In this paper, we have proposed a dual-core PCF with a rectangular air-hole lattice structure and the analyte liquid is filled into the central air holes. The configuration of the proposed dual-core PCF is designed by COMSOL Multiphysics software which is based on FEM (Finite Element Method). We have calculated the sensitivity of the proposed dual-core PCF and compared with some other reported PCFs which shows greater sensitivity.

2 PCF Design

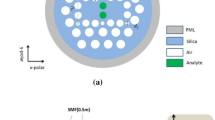

The proposed PCF consists of a periodic array of rectangular air holes lattice structure and the analyte liquid is filled into the central air holes, here we take the diameter of circular air holes are \( d = 3\,\upmu{\text{m}} \) and hole-to-hole distance pitch \( \Lambda = 5\,\upmu{\text{m}} \), respectively, and the background material of PCF is taken as silica. The refractive index of silica and air is 1.45 and 1, respectively, and na is varies in the range of 1.33–1.41. The geometry of proposed dual-core PCF is shown in Fig. 1.

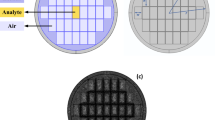

Dual-core PCF coupling can be explained by four super modes in the x-polarization and y-polarization. These four super modes can be created due to the individual cores. Figure 2 shows the distribution of electric field of the four super modes. Using Eq. (1), we calculate coupling length at different wavelengths. First, we calculate the refractive indices of four super modes and then the difference of effective refractive indices for x- and y-polarized light has been calculated, after that, their coupling lengths have been calculated from the Eq. (1).

The coupling length of the dual-core PCF is defined as [9, 14]

where propagation constants of i-polarized even and odd super mode are represented as \( \beta_{e }^{i} \) and \( \beta_{o}^{i} \), respectively. The effective refractive indexes of i-polarized even and odd super mode are represented as \( n_{e}^{i} \) and \( n_{o}^{i} \), respectively.

Due to the theory of mode coupling, power transfer of the dual-core PCF after a length L is defined as [15]

For the sensor purpose, we calculate the sensitivity of the dual-core PCF by shifting of the peaks with the variation of refractive index of analyte liquid. The sensitivity of the dual-core PCF is defined as [16]

where the shift of the transmission spectra is represented as Δλpeak and the change of the analyte refractive index is represented as Δna.

3 Simulation Results and Discussion

Figure 3a shows the effective refractive index variation of four super modes of PCF with wavelength when the analyte liquid na = 1.3 is filled into the central air holes. The effective refractive index decreases with increasing wavelength. Figure 3b shows that the effective refractive index difference \( (\Delta n_{eo} ) \), which is \( \Delta n_{eo} = \left| {n_{e} - n_{o} } \right| \). The effective refractive index difference \( (\Delta n_{eo} ) \) increases when the wavelength increases, because as the wavelength increases light spreads into the cladding, confinement is less, so effective refractive index difference increases.

Figure 4a shows the coupling length variation of the x- and y-polarized light with wavelength. According to the mode coupling theory, the optical power transferring from one fiber core to the other core along PCF after a length L. Obviously, coupling lengths of dual-core PCF vary with wavelengths. It can be seen that the coupling length of y-polarized light is larger than x and as wavelength increases the coupling length decreases. Figure 4b shows the power transmission curve of dual-core PCF for the x-polarized light and y-polarized light with a length of 1 cm. The power transmission curve of the proposed PCF is sinusoidal.

The numerical shift in wavelength for different analyte liquid is shown in Fig. 5. This curve gives the maximum sensitivity of the proposed dual-core PCF. According to calculated result, the sensitivity of the proposed dual-core PCF increases when na is increases. From the result, the highest sensitivity of 9,400 nm/RIU can be achieved when na = 1.41 at the wavelength of 1193 nm. The lowest sensitivity of 5,150 nm/RIU can be achieved when na = 1.33 at the wavelength of 1732 nm. The comparison of the sensitivity of the proposed dual-core PCF and some other PCFs is shown in Table 1.

4 Conclusion

In this paper, we proposed a highest sensitivity dual-core PCF by using Finite Element Method. From the numerical results, it is clear that the proposed PCF sensor can detect the range from 1.33 to 1.41. The maximum sensitivity of 9,400 nm/RIU can be achieved when the refractive index of the analyte na = 1.41. The lowest sensitivity of 5,150 nm/RIU can be achieved when na = 1.33. High sensitivity gives fast, real-time, and easy detection.

References

Birks TA, Knight JC, Russell PSJ (1997) Endlessly singlemode photonic crystal fiber. Opt Lett 22:961–963

Ju J, Jin W et al (2003) Properties of a highly birefringent photonic crystal fiber. IEEE Photon Technol Lett 15:1375–1377

Ranka JK, Windeler RS, Stentz AJ (2000) Visible continuum generation in air–silica microstructure optical fibers with anomalous dispersion at 800 nm. Opt Lett 25:25–27

Knight JC, Arriaga J, Birks TA et al (2000) Anomalous dispersion in photonic crystal fiber. IEEE Photon Technol Lett 12:807–809

Sinha RK, Varshney SK (2003) Dispersion properties of photonic crystal fibers. Microw optical Technol Lett 37:129–132

Liu Z, Tse ML, Wu C, Chen D, Lu C, Tam HY (2012) Intermodal coupling of supermodes in a twin core photonic crystal fiber and its application as a pressure sensor. Opt Express 20:21749–21757

Dhara P, Singh VK (2015) Effect of MMF stub on the sensitivity of a photonic crystal fiber interferometer sensor at 1550 nm. Opt Fiber Technol 21:154–159

Rindorf L, Bang O (2008) Sensitivity of photonic crystal fiber grat-ing sensors: biosensing, refractive index, strain and temperature sensing. J Opt Soc Am B 25:310–324

Wang Z, Taru T, Birks TA, Knight JC (2007) Coupling in dual-core photonic bandgap fibers: theory and experiment. Opt Express 15:4795–4803

Lagsgaard J (2005) coupling in twin-core photonic bandgap fibers. Opt Lett 30:3281–3283

Lagsgaard J, Bang O, Bjarklev A (2004) Photonic crystal fiber design for broadband directional coupling. Opt Lett 29:2473–2475

Saitoh K, Florous NJ, Koshiba M, Skorobogatiy M (2005) Design of narrow band-pass filters based on the resonant-tunneling phenomenon in multi-core photonic crystal fibers. Opt Express 13:10327–10335

Saitoh K, Sato Y, Koshiba M (2004) Polarization splitter in three-core photonic crystal fibers. Opt Express 12:3940–3946

Saitoh K, Sato Y, Koshiba M (2003) Coupling characteristics of dual-core photonic crystal fiber couplers. Opt Express 11:3188–3195

Huang WP (1994) Coupled mode theory for optical waveguides: an overview. J Opt Soc Am A 11:963–983

Beatrand G, Alireza H, Majid FF, Andrei K, Skorobogatiy MA (2007) Photonic bandgap fiber-based surface plasmon resonance sensors. Opt Express 15:11413–11426

Rindorf L, Bang O (2008) Highly sensitive refractometer with a photonic-crystal-fiber long-period grating. Opt Lett 33:563–565

Shuai B, Xia L, Zhang Y, Liu D (2012) A multi-core holey fiber based plasmonic sensor with large detection range and high linearity. Opt Express 20:5974–5986

Tian M, Lu P, Chen L, Lv C, Liu D (2012) All-solid D-shaped photonic fiber sensor based on surface plasmon resonance. Opt Commun 285:1550–1554

Hasan MR, Akter S, Ahmed K, Abbott D (2017) Plasmonic refractive index sensor employing niobium nanofilm on photonic crystal fiber. IEEE Photon Technol Lett 1041–1135

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chaudhary, V., Kumar, D. (2020). Design and Analysis of Refractive Index Sensor Based on Dual-Core Photonic Crystal Fiber (DC-PCF) with Rectangular Air Hole Lattice Structure. In: Janyani, V., Singh, G., Tiwari, M., d’Alessandro, A. (eds) Optical and Wireless Technologies . Lecture Notes in Electrical Engineering, vol 546. Springer, Singapore. https://doi.org/10.1007/978-981-13-6159-3_22

Download citation

DOI: https://doi.org/10.1007/978-981-13-6159-3_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6158-6

Online ISBN: 978-981-13-6159-3

eBook Packages: EngineeringEngineering (R0)