Abstract

Regions of a few nanometers at the surface or interface of a material exhibit various functional properties, which differ from those of the bulk because the electrons and/or ions receive different potentials due to the incoherent atomic arrangement. High-quality epitaxial films of functional materials called “nanolayers” are important to utilize such functional properties. However, fabrication of high-quality nanolayers of complex materials with complicated crystal structures is usually challenging due to the difference in the thermochemical properties of the constituents. In this chapter, epitaxial growth techniques, especially “reactive solid-phase epitaxy” of functional oxides and chalcogenides, are reviewed based on the authors’ efforts. Additionally, this chapter reviews several modulation methods of optical, electrical, and magnetic properties of functional oxide nanolayers.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Epitaxial Growth and Characterization of Functional Nanolayers

Regions of a few nanometers at the surface or interface of a material often exhibit various functional properties, which differ from those of the bulk due to the fact that the electrons and/or ions receive different potentials due to the incoherent atomic arrangement. High-quality epitaxial films of functional materials called “nanolayers” are important to utilize such functional properties.

In this chapter, epitaxial growth techniques, especially “reactive solid-phase epitaxy” of functional oxides and chalcogenides, are reviewed based on the authors’ efforts. Additionally, this chapter reviews several modulation methods of optical, electrical, and magnetic properties of functional oxide nanolayers.

2 Pulsed Laser Deposition

Pulsed laser deposition (PLD) is a physical vapor deposition technique [1]. By irradiating focused laser pulses of an excimer laser or a higher (3rd or 4th) harmonic of a Nd:YAG laser onto the target material (single crystals or ceramics or powder), which is located in an ultrahigh vacuum chamber, films can be deposited on the substrate as a result of vaporization of the target materials occur during laser irradiation (Fig. 10.1). PLD is one of the most powerful techniques for epitaxial film growth of inorganic solids, especially oxides. It has several advantages compared to the other deposition techniques, such as sputtering. In the case of PLD, the chemical composition of the resultant film is almost same as that of the target material, although generally it differs from the target because the chemical species show different sputtering yields in the case of sputtering. Moreover, the atmosphere in the PLD chamber can be widely controlled from an ultrahigh vacuum to ~102 Pa, allowing a thermodynamically nonequilibrium crystalline phase of a material to be fabricated.

As an example, PLD growth and characterization of the SrTiO3-SrNbO3 solid solution system are explained. SrTiO3 has attracted increasing attention as the next generation of oxide electronics [2]. Doping with the appropriate substituent, such as Nb5+ (Ti4+ site) or La3+ (Sr2+ site), easily varies the charge carrier concentration of SrTiO3 from insulating to metallic (n 3D ~ 1021 cm−3). Electron-doped SrTiO3 is one of the most extensively studied materials for thermoelectric applications [3, 4]. In 2001, Okuda et al. [5] synthesized Sr1−x La x TiO3 (0 ≤ x ≤ 0.1) single crystals by the floating-zone method. They reported that the crystals exhibit a large power factor (S 2 · σ) of 2.8–3.6 mW m−1 K−2 at room temperature. Later, Ohta et al. reported the carrier transport properties of Nb- and La-doped SrTiO3 single crystals (carrier concentration, n ~ 1020 cm−3) at high temperatures (~1000 K) to clarify the intrinsic thermoelectric properties of these materials [6].

The experimental discovery of unusually large thermopower outputs from superlattices and two-dimensional electron gases in SrTiO3 [7, 8] spurred substantial research efforts into SrTiO3 superlattices [9, 10] and heterostructures [11,12,13] for thermoelectric applications. For example, a superlattice composed of one unit cell (uc) of SrTi0.8Nb0.2O3 and 10 uc of SrTiO3 exhibits a giant thermopower, most likely due to an electron confinement effect. Although electron confinement is strongly correlated with the electronic structure [14, 15], a full understanding of the fundamental electronic phase behavior of the SrTi1−x Nb x O3 solid solution system has yet to be developed.

Although high-quality single crystals of SrTi1–x Nb x O3 species with x > 0.1 are not available due to the low solubility limit of Nb in the lattice [16], epitaxial films with these material compositions can be fabricated by PLD [17]. As summarized in Fig. 10.2, pure SrTiO3 (space group \(Pm\bar{3}m\), cubic perovskite structure, a = 3.905 Å) is an insulator with a bandgap of 3.2 eV. The bottom of the conduction band is composed of triply degenerate, empty Ti 3d−t 2g orbitals, while the top of the valence band is composed of fully occupied O 2p orbitals [18]. The valence state of Ti ions in crystalline SrTiO3 is 4 + (Ti 3d0). On the other hand, pure SrNbO3 (space group \(Pm\bar{3}m\), cubic perovskite structure, a = 4.023 Å) is a metallic conductor [19,20,21]. The valence state of the Nb ion is 4 + (Nb 4d1). In between SrTiO3 and SrNbO3 in the SrTi1−x Nb x O3 ss, there are two possible types of valence state changes in the Ti and Nb ions, as shown in Fig. 10.2b and c. In the case of isovalent substitution (Fig. 10.2b), the mole fraction of Ti4+ proportionally decreases with increasing Nb4+ (x). On the other hand, heterovalent substitution, in which two Ti4+ or Nb4+ ions are substituted by adjacent (Ti3+/Nb5+) ions, can occur, as shown in Fig. 10.2c. Based on these considerations, we focused on the valence state changes of Ti and Nb ions in the SrTi1−x Nb x O3 ss.

Reprinted with permission from [22]. © 2017 AIP

Schematic of the crystal structure and possible valence state changes in the SrTiO3-SrNbO3 solid solution system. a Schematic of the crystal structure. Pure SrTiO3 is an insulator with a bandgap of 3.2 eV, in which the valence state of the Ti ions (blue, TiO6) is 4 + (Ti 3d0). In contrast, pure SrNbO3 is a metal, in which the valence state of the Nb ions (Red, NbO6) is 4 + (Nb 4d1). b, c Possible valence state changes of the Ti and Nb ions in the SrTiO3-SrNbO3 solid solution system: b isovalent substitution, where Ti4+ is substituted by Nb4+ and c heterovalent substitution, where two Ti4+/Nb4+ ions are substituted by adjacent Ti3+/Nb5+ ions.

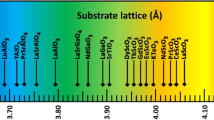

Zhang et al. [22] fabricated approximately 100 nm-thick SrTi1−x Nb x O3 (x = 0.05, 0.1, 0.2, 0.3, 0.4, 0.5, 0.55, 0.6, 0.7, 0.8, 0.9, and 1.0) epitaxial films by PLD using dense ceramic disks of a SrTiO3-SrNbO3 mixture. Insulating (001) LaAlO3 (pseudo-cubic perovskite, a = 3.79 Å) was used as the substrate. The growth conditions were precisely controlled with a substrate temperature of 850 ℃, an oxygen pressure of ~10−4 Pa, and a laser fluence of 0.5–1 J cm−2 pulse−1, yielding a growth rate of 0.3 pm pulse−1.

Figure 10.3a summarizes the Xray reciprocal space mappings (RSMs) around the \((\overline{ 1} 0 3 )\) diffraction spot of LaAlO3 (overlaid). Intense diffraction spots from \((\overline{ 1} 0 3 )\) SrTi1−x Nb x O3 are seen together with those from the LaAlO3 substrate, indicating that incoherent heteroepitaxial growth of the target materials occurs for all x compositions. The peak positions of the diffraction spots from each composition correspond well with the cubic line (q z /q x = −3), suggesting that no epitaxial strain is induced in the films. It should be noted that a slight tetragonal distortion is observed in the x = 0.4 (c/a = 1.0057) and 0.5 (c/a = 1.0050) samples.

Reprinted with permission from [22]. © 2017 AIP

Crystallographic characterization of the SrTi1−x Nb x O3 epitaxial films on a (001) LaAlO3 single-crystal substrate. a Xray reciprocal space mappings around the \((\bar{1}03)\) diffraction spot of the SrTi1−x Nb x O3 epitaxial films. The location of the LaAlO−3 diffraction spot, (q x /2π, q z /2π) = (−2.64, 7.92), corresponds to the pseudo-cubic lattice parameter of LaAlO3 (a = 0.379 nm). Red symbols (+) indicate the peak positions of the SrTi1−x Nb x O3 epitaxial films. b Changes in the lattice parameters of the SrTi1−x Nb x O3 films (circles, left axis) superimposed with isovalent/heterovalent substitution lines (black line: isovalent substitution, gray line: heterovalent substitution, right axis), calculated using Shannon’s ionic radii [23]. c Changes in the B-site occupation by [Ti4+/Nb4+] derived from the data in (b).

From the RSMs of the SrTi1−x Nb x O3 films, we extracted the lattice parameters using the formula a = (2π/q x · 2π/q x · 6π/q z )1/3. Figure 10.3b plots the lattice parameters of the SrTi1−x Nb x O3 film as a function of x. We observed an M-shaped trend along with a general increase in the lattice parameter with increasing x. In order to analyze the changes in the lattice parameter, we calculated the average ionic radii in the crystal structure and used Shannon’s ionic radii as a comparison [23]: Ti4+ (60.5 pm), Ti3+ (67.0 pm), Nb4+ (68.0 pm), and Nb5+ (64.0 pm). In the ranges of 0.05 ≤ x ≤ 0.3 and x ≥ 0.6, the observed lattice parameters closely follow the heterovalent substitution line, suggesting that two Ti4+ or Nb4+ ions are substituted by adjacent (Ti3+/Nb5+) ions [24]. On the other hand, at x = 0.4 and 0.5, the observed lattice parameter correspond well with the isovalent substitution line. Moreover, at x = 0.5, the B-site occupation of [Ti4+/Nb4+] is almost 100%, as shown in Fig. 10.3c.

Figure 10.4a shows a cross-sectional HAADF-STEM image of the SrTi0.5Nb0.5O3 film. Periodical mismatch dislocations with intervals of ~8.5 nm are seen at the heterointerfaces. If the strain in the thin film is fully relaxed by such misfit dislocations, it is possible to calculate the spacing between dislocations (d) from \(d = {\mathbf{b}}/\delta\), where b is the Burgers vector and δ is the lattice mismatch between thin film and substrate [25]. Using the lattice parameters obtained from XRD [δ = \((q_{{x\,{\text{sub}}}} - q_{{x\,{\text{film}}}} )/q_{{x\,{\text{film}}}} = + 0.0435\)], the estimated dislocation spacing is 8.7 nm, suggesting that the dislocations fully relax the strain in the film. Although superspots originating from the (111) diffraction are often observed in AB0.5B’0.5O3 compositions that crystallize in B-site-ordered double perovskite structures [26], they are not observed in the SrTi0.5Nb0.5O3 film (Fig. 10.4b). This is most likely due to the slight tetragonal distortion of the crystal structure. Figure 10.4 shows the EELS spectra acquired around the Ti L (c) and O K edges (d). The reported EELS spectra of Ti3+/Ti4+ [27] and Nb4+/Nb5+ [28] are plotted for comparison. In the Ti L edge spectrum (c), t 2g and e. g. peak splitting is clearly observed for Ti L 3, indicating that the dominant valence state of Ti is 4+. In the O K edge spectra (d), two intense peaks (assigned as A and B) are clearly observed where peak B has a higher intensity than peak A. A previous study noted that this is a characteristic feature of Nb4+ [28]. The peak intensity ratio A/B is calculated to be 0.66, which roughly corresponds with the Nb4+ spectrum (0.66).

Reprinted with permission from [22]. © 2017 AIP

Electron microscopy analyses of a SrTi1−x Nb x O3 film with a composition of x = 0.5. a HAADF-STEM image acquired with the electron beam incident along the <100> direction. Periodic misfit dislocations (~8.5 nm interval) at the heterointerface are indicated by red lines. b Selected-area electron diffraction pattern acquired with the electron beam incident along the <110> direction. c, d EELS spectra acquired around the c Ti L edge and d O K edge. EELS spectra for Ti3+/Ti4+ [27] and Nb4+/Nb5+ [28] from previous studies are also plotted for comparison.

By using abovementioned films, Zhang and Ohta et al. clarified the thermoelectric phase diagram for the SrTi1−x Nb x O3 (0.05 ≤ x ≤ 1) solid solution system (Fig. 10.5). They observed two thermoelectric phase boundaries in the system, which originate from the step-like decrease in the carrier effective mass at x ~ 0.3 and from the local minimum in the carrier relaxation time at x ~ 0.5. The origins of these phase boundaries are related to the isovalent/heterovalent B-site substitution. The parabolic Ti 3d orbitals dominate the electron conduction for compositions with x < 0.3, whereas the Nb 4d orbital dominates when x > 0.3. At x ~ 0.5, a tetragonal distortion of the lattice, in which the B-site is composed of Ti4+ and Nb4+ ions, leads to the formation of tail-like impurity bands, which maximize electron scattering. These results provide a foundation for further research to improve the thermoelectric performance of SrTi1−x Nb x O3.

Reprinted with permission from [22]. © 2017 AIP

Thermoelectric phase diagram for the SrTiO3-SrNbO3 solid solution system. The thermoelectric power factor (S 2 · σ) of the SrTiO3-SrNbO3 solid solution system is plotted along with the previously reported values [7]. The x dependence of S 2 · σ is shown in the inset. The system’s thermoelectric phase boundaries are clearly seen at x ~0.3 and ~0.5.

3 Reactive Solid-Phase Epitaxy

As explained above, PLD is a powerful technique for epitaxial film growth of metal oxides. Although there are many reports on epitaxial oxide film growth by the PLD method, it is still difficult to fabricate epitaxial films of complex oxides composed of different vapor pressure elements, especially alkali metals. Since complex oxides have high melting points (>1500 ℃), substrates must be heated at high temperature (>800 ℃ : ~60% of the melting point) in a vacuum during PLD. If the multiplex elements have different vapor pressures at the substrate temperature, the chemical composition of the resultant film completely differs from that of the target because re-vaporization of the high vapor pressure element occurs during deposition.

To overcome this issue, Ohta et al. developed the “Reactive Solid-Phase Epitaxy (R-SPE)” method in 2003 (Fig. 10.6) [29]. In this method, an epitaxial film of a monoxide, which is a component of a complex oxide, is fabricated by PLD. Then the film is heated at high temperatures with another member of the target oxide (thin film or powder). During the heat treatment, a solid-solid reaction between the monoxide film and the other member elements occurs while maintaining the crystallographic orientation. Using the R-SPE method, epitaxial films of InMO3(ZnO) m (M = Ga and In, m = integer) [29], ZnRh2O4 [30], LaCuOCh (Ch = S or Se) [31], and Na x CoO2 (x ~ 0.8) [32] have been fabricated. Thus, the R-SPE method effectively fabricates epitaxial films of complex oxides composed of high vapor pressure elements. In this section, recent progress of “reactive solid-phase epitaxy” of functional oxides and chalcogenides is reviewed.

Schematic diagram of the “Reactive Solid-Phase Epitaxy” method. A bilayer laminate composed of a thin epitaxial layer of simple oxide (A–O or B–O or C–O) or metal grown on a substrate and a polycrystalline layer or powder source of target A k B m C n O x is thermally annealed at high temperatures (~1000 ℃). The solid-state reaction at high temperatures leads to the formation of a thin single-crystalline layer on the substrate, which may act as “an epitaxial template” for successive homoepitaxial SPE growth of the film

3.1 Na≈2/3MnO2 Epitaxial Film

Layered alkali ion-containing metal oxides (LAMO), A x MO2 (A: alkali metal and M: transition metal) have received considerable interest as candidate materials for energy storage and conversion applications. This is because their chemical potential can be readily controlled. Changing the concentration of A + in the interspace between adjacent MO2 layers tunes the valence state of the M ion. In particular, there have been many studies on cobalt-based A x CoO2 because the A + concentration is easily controlled and these oxides possess a two-dimensional electronic structure. Li x CoO2 (0 ≤ x ≤ 1) is one of the best cathode active materials in commercial Li-ion batteries because the Li+ concentration can be controlled by an electrochemical process [33, 34]. Meanwhile, Na x CoO2 (x ~ 0.8) is a promising thermoelectric material, which can directly convert a temperature difference into electricity. Additionally, it exhibits a rather large thermopower even though it displays metallic conductivity due to the two-dimensional nature of the electronic structure [35, 36]. Furthermore, the two-dimensional electronic structure of the bilayer hydrated crystal Na≈0.3CoO2 · 1.3H2O allows it to exhibit superconductivity at a critical temperature T c of ~4 K [37, 38].

Unlike A x CoO2 systems, the physical properties of A x MnO2 have yet to be clarified, although Na x MnO2 has recently been proposed as a new candidate for the cathode active material in Na-ion batteries [39,40,41] because Mn (Clarke number: 0.09) is more abundant than Co (Clarke number: 0.004). At least two crystallographic phases of NaMnO2 are known; low-temperature α-NaMnO2 [39, 42] has an O3 layered structure with monoclinic symmetry and high-temperature β-NaMnO2 [40] has a Pmnm structure with orthorhombic symmetry. It should be noted that the crystal symmetry of Na x MnO2 strongly depends on x. The low-temperature phase Na0.67MnO2 [41, 43] has a P2 layered structure with hexagonal symmetry. Recently, Billaud et al. [41] reported that Na0.67MnO2 with a P2 structure exhibits a high capacity of 175 mA h g−1 with a good capacity retention.

However, there are a few studies on the electrical conductivity of Na x MnO2 [44]. The most rational reason is the lack of large single crystals. It is difficult to measure the intrinsic electrical property using powder compacts due to severe electron scattering. High-quality epitaxial films may be a solution to clarify the electrical conductivity of Na x MnO2.

In 2017, Katayama et al. fabricated Na x MnO2 epitaxial films by the R-SPE method using the following procedure (Fig. 10.7) [45]. First, a 70 nm-thick MnO y thin film was heteroepitaxially grown on a (0001) α-Al2O3 substrate (10 × 10 × 0.5 mm) by PLD using a KrF excimer laser (λ = 248 nm, 20 ns, 10 Hz, ~1.5 J cm−2 pulse−1) to ablate the Mn2O3 ceramic disk. During the deposition, the substrate temperature and oxygen pressure were kept at 700 ℃ and ~10−2 Pa, respectively. After deposition, the film was cooled to RT in the PLD chamber. The film’s top surface was completely covered with another sapphire plate, and the sandwiched specimen was subsequently preserved in Na2CO3 powder. Then the film was heated at 700 ℃ for 30 min in air to supply Na+ and O2− into the MnO y film. During heat treatment, the film color changed from light brown to dark brown.

Reprinted with permission from [45]. © 2017 ACS

Schematic of the crystal structure change from MnO y to Na x MnO2 during R-SPE [Gray: Na, blue: Mn, red: O]. First, a spinel-type MnO y film is heteroepitaxially grown on a sapphire substrate. The MnO y epitaxial film, covered with Na2CO3 powder, is heated at 700 ℃ in air. As a result, Na+ ions are supplied into the MnO y film together with O2− ions during the heating, forming the Na x MnO2 epitaxial film with a layered crystal structure.

Figure 10.8 shows a cross-sectional HAADF-STEM image of the R-SPE grown Na≈2/3MnO2 film around the interface observed from the direction of Na≈2/3MnO2||α-Al2O3. The stripe patterns correspond to the layered structure of Na≈2/3MnO2. It should be noted that an interfacial layer is not observed, confirming that the present sample has an atomically sharp interface between the film and substrate, contrary to the previously reported observation for a Na≈0.8CoO2 film.

Reprinted with permission from [45]. © 2017 ACS

HAADF-STEM image of the Na≈2/3MnO2/α-Al2O3 substrate interface. Incident direction of the electron beam is \([ 1\overline{ 1} 0 0 ]\) Na≈2/3MnO2. The atomically sharp heterointerface is clearly seen.

Figure 10.9 summarizes the temperature (T) dependence of the electrical conductivity (σ) for the Na≈2/3MnO2 and hydrated Na≈0.61MnO2 ≈ 0.42H2O epitaxial films. It should be noted that the σ – T curves for both films do not show a remarkable hysteresis in the heating–cooling cycles ranging from RT to 400 K, suggesting that the absorbed water does not significantly contribute to σ because the surface-adsorbed water should be released at 100–150 ℃, although a slight deviation from a straight line at ~100 ℃ is observed in hydrated Na≈0.61MnO2 ≈ 0.42H2O film. At RT, σ of the Na≈2/3MnO2 epitaxial film is ~1 mS cm−1, which is two orders of magnitude larger than that of an α-Na0.70MnO2.25 single crystal (~0.5 μS cm−1). In contrast, σ of the Na≈0.61MnO2 ≈ 0.42H2O film is ~0.1 mS cm−1, which is comparable to that of the Na x MnO2 · nH2O ceramic (~0.05 mS cm−1). In both cases, σ increases exponentially with temperature because electron hopping becomes faster at higher temperatures. The activation energy for electron hopping (E a) observed for both films in the 300–400 K range is 0.47 eV, which is comparable to those of other Mn3+/Mn4+-containing oxides, such as α-MnO2−δ , Li x MnO2, and LiMn2O4. In contrast to Na≈0.35CoO2 · 1.3H2O, the electron hopping conductivity of Na≈2/3MnO2 decreases by the hydration treatment. This decrease is most likely because the intercalated water molecules affect the ratio of Mn3+/Mn4+.

Reprinted with permission from [45]. © 2017 ACS

Electrical conductivity. Temperature dependence of the electrical conductivity for the Na≈2/3MnO2 and the Na≈0.61MnO2 ≈ 0.42H2O films measured by the AC impedance method in air. The resultant films show electrical conductivities of ~1 mS cm−1 for Na≈2/3MnO2 film and ~0.1 mS cm−1 for Na≈0.61MnO2 ≈ 0.42H2O film at RT. Inset shows the σT–1/T plots for both films; the activation energy (E a) for electron hopping conduction is 0.47 eV.

3.2 Li4Ti5O12 Epitaxial Film

Li4Ti5O12 (S.G. \(Fd\overline{3} m\)) is one of the most promising anode active materials of solid Li-batteries, [46, 47] due to its structural stability during charge/discharge reactions [48] with excellent reversibility [49, 50] and a long cycle life [51]. Although epitaxial film growth of Li4Ti5O12 by PLD has been reported, [52, 53] the target ceramic containing excess Li species is required to fabricate stoichiometric Li4Ti5O12 thin films. On the contrary, Li et al. fabricated an amorphous Li4Ti5O12 film by PLD on a (001) SrTiO3 single-crystal substrate at room temperature with a stoichiometric Li4Ti5O12 target, and heated the amorphous film with molten LiNO3 at 600 ℃ in air. As a result of this “solid–liquid phase epitaxy”, they successfully fabricated an epitaxial film of single-phase Li4Ti5O12 [54].

The solid–liquid phase epitaxy procedure for the growth of Li4Ti5O12 films is schematically illustrated in Fig. 10.10. Step 1(a): Amorphous Li-Ti-O films (100 nm thick) are deposited at RT on (001) SrTiO3 single-crystal substrates (area: 10×10 mm2, thickness: 0.5 mm) by PLD. The in-plane lattice mismatch is too large for Li4Ti5O12 to coherently grow on (001) SrTiO3 substrate, where the lattice mismatch between cubic Li4Ti5O12 (the half of a-axis lattice parameter, a/2 = 0.4176 nm) and SrTiO3 (a = 0.3905 nm) is estimated to be −6.9%. A KrF excimer laser with an energy fluence of ~2 J cm−2 pulse−1 and a repetition rate of 10 Hz is used to ablate a ceramic target of stoichiometric Li4Ti5O12. The oxygen pressure during film deposition is kept at a low P O2 of 1.0 × 10−3 Pa and the deposition rate is 3.3 nm min−1. Step 2(b): The resultant film is covered with LiNO3 powder. Then it is heated at 600 ℃ for 30 min in air at temperature increasing rate of 40 ℃/min in an Al2O3 crucible using an electric furnace. During the heating process, the LiNO3 powder melts due to its low melting point of 261 ℃ and entirely covers the Li-Ti-O film at 600 ℃. The film is naturally cooled to RT in the furnace. Step 3(c): The resultant film is washed by distilled water since the film surface is covered with the remaining LiNO3 film. The resultant film surface looks very clean, indicating that LiNO3 is successfully removed.

Reprinted from [54]. © 2016 The Japan Society of Applied Physics

Solid–liquid phase epitaxy of the Li4Ti5O12 film. a Step 1: An amorphous Li4Ti5O12 film is deposited at RT on a (001) SrTiO3 single-crystal substrate by PLD using a dense Li4Ti5O12 ceramic as the target. b Step 2: The resultant film is heated at 600 ℃ for 30 min in air with a LiNO3 powder, which melts during the heating process, in an Al2O3 crucible using electric furnace. Then the film is naturally cooled down to RT in the furnace. c Step 3: The Li4Ti5O12 epitaxial film is obtained after the resultant film is washed with distilled water since the film surface is covered with remaining LiNO3 film.

Figure 10.11a–c shows the out-of-plane XRD patterns for Li4Ti5O12 films [(a) as-deposited, (b) heated at 600 ℃ without LiNO3, and (c) heated at 600 ℃ with LiNO3]. Only the intense diffraction peaks of 00 l SrTiO3 are observed in the as-deposited Li4Ti5O12 film, indicating that the film is amorphous (Fig. 10.11a). After heating the amorphous Li4Ti5O12 film without LiNO3 powder at 600 ℃ in air, the 004 anatase-TiO2 diffraction peak is observed, but the Li4Ti5O12 diffraction peak is not seen in the out-of-plane XRD pattern (Fig. 10.11b). The c-axis lattice parameter (0.954 nm) for the TiO2 phase is almost the same as 0.951 nm for the pure anatase-TiO2 bulk [55].

Reprinted from [54]. © 2016 The Japan Society of Applied Physics

Out-of-plane XRD patterns of the Li4Ti5O12 films [a as-deposited, b heated at 600 ℃ without LiNO3 (solid-phase epitaxy), c heated at 600 ℃ with LiNO3 (solid–liquid phase epitaxy)]. Only intense diffraction peaks of 00 l SrTiO3 are seen in the as-deposited Li4Ti5O12 film (a), indicating that the as-deposited film is amorphous. The intense diffraction peak of 004 Li4Ti5O12 is observed in (c), although 004 anatase TiO2 is crystallized when the film is heated without LiNO3 powder (b). FWHM of the Xray rocking curve (Δω) for the 004 Li4Ti5O12 is ~0.8° (d). e In-plane XRD pattern of the Li4Ti5O12 film grown by solid–liquid phase epitaxy. Only the intense diffraction peak of 400 Li4Ti5O12 is seen together with h00 SrTiO3. The ϕ scan of 400 Li4Ti5O12 diffraction [(e) inset] shows a fourfold rotational symmetry with every 90° rotation originating from the cubic symmetry of Li4Ti5O12 lattice.

In contrast, the intense diffraction peak of 004 Li4Ti5O12 is observed after the film is heated with molten LiNO3 at 600 ℃ (Fig. 10.11c). The full width at half maximum (FWHM) value of the out-of-plane rocking curve (Δω) for 004 Li4Ti5O12 diffraction is ~0.8°, indicating that the Li4Ti5O12 film is preferentially oriented perpendicular to the substrate surface (Fig. 10.11d). The chemical composition of the Li4Ti5O12 film could not be accurately estimated when the Li/Ti ratio is an extremely large value of ~5.0, presumably due to the residual adhesive LiNO3 and/or Li species incorporated into SrTiO3 substrate. However, the film density characterized by the Xray reflectivity measurements for the Li4Ti5O12 film is 3.5 g cm−3, which is consistent with the 3.48 g cm−3 of the Li4Ti5O12 phase. In contrast, that of the Li4Ti5O12 film heated without LiNO3 is 4.1 g cm−3, approaching 3.90 g cm−3 of the anatase TiO2 due to the decrease of in Li content in the film. At this stage, the actual vaporization temperature of Li in the Li4Ti5O12 film has yet to be examined, but these results suggest that molten LiNO3 plays an essential role in suppressing the vaporization of Li species and enables crystallization of the Li4Ti5O12 phase at relatively low temperature (600 ℃) by solid–liquid phase epitaxy.

3.3 KFe2As2 Epitaxial Film

A novel attractive property has recently been theoretically predicted for KFe2As2. Pandey et al. [56] reported that KFe2As2, which is the end member of the 122-type iron-based superconductors (Ba1–x K x ) Fe2As2 (i.e., x = 1) with a critical temperature ≈ 3 K [57], may exhibit a large spin Hall conductivity (SHC), which is comparable to that of Pt [58]. That is, it exhibits 104 times larger SHC (2 × 104 Ω−1 m−1) than that of a semiconductor (0.5 Ω−1 m−1) [59]. Such a high SHC originates from the strong spin-orbit coupling of the Fe 3d states with Dirac cones below the Fermi level of heavily hole-doped KFe2As2. Indeed, high-resolution angle-resolved photoemission spectroscopy experiments show that the electron pocket at the M point of (Ba1–x K x )Fe2As2 completely disappear for KFe2As2 due to its heavily self-hole-doped nature (Ba2+ ↔ K+ + hole) [60].

Because KFe2As2 contains alkali metal K as its main constituent, it is very air sensitive. Therefore, the thin-film growth of KFe2As2 is difficult due to two intrinsic properties: its extremely hygroscopic nature and the high vapor pressure of potassium. Thin-film growth of KFe2As2 and electrical measurements with device patterning are challenging issues. These issues were solved by combining room-temperature pulsed laser deposition using K-rich KFe2As2 bulk targets with thermal crystallization in a KFe2As2 powder after encapsulation in an evacuated silica-glass tube. All of the setup processes must be conducted in a vacuum chamber and a dry Ar atmosphere in a glove box (Fig. 10.12) [61]. Optimized KFe2As2 films on (La, Sr)(Al, Ta)O3 single-crystal substrates are obtained by crystallization at 700 ℃. These films are strongly c-axis oriented. Electrical measurements were performed with thin films protected by grease passivation to block reaction with the atmosphere. The KFe2As2 films exhibit a superconductivity transition at 3.7 K, which is the same as that of bulk KFe2As2. This result is the first demonstration of a superconducting KFe2As2 thin film.

Reprinted from ref. [61]. Copyright © 2014 American Chemical Society

Solid-phase epitaxy for KFe2As2 film growth. a Set up before thermal annealing. b XRD patterns of the films annealed at T a = 500–800 ℃ buried in KFe2As2 powder. b Out-of-plane rocking curve of the 002 diffraction of the KFe2As2 film annealed at T a = 700 ℃. c Pole figure of the 103 diffraction of the KFe2As2 film annealed at T a = 700 ℃.

The obtained KFe2As2 films are, however, not epitaxial films, but c-axis orientated ones without an in-plane orientation. This is attributed to the maximum thermal annealing temperature up to 700 ℃ in the conventional annealing method sealed in an evacuated silica-glass tube. When we raised the annealing temperature to >700 ℃, the films decompose into Fe2As, FeAs, and Fe. It indicates that the gas-tightness of this synthesis condition is poor >700 ℃ for K and the alkali metal component K does not remain in the films.

Therefore, an improved solid-phase epitaxy technique using a custom-made alumina vessel, which realizes a high annealing temperature of 1000 ℃ without vaporization of K from the films, was developed, and high-quality heteroepitaxial KFe2As2 thin films on MgO single crystals were successfully obtained (Fig. 10.13) [62]. This result demonstrates that this solid-phase epitaxy technique is a powerful method for the complex compounds with extremely high vapor pressures, such as K.

Reprinted from ref. [62]. Copyright © 2016 The Japan Society of Applied Physics

Improved solid-phase epitaxy for KFe2As2 film growth.

3.4 (Sn, Pb)Se Epitaxial Film

SnSe is usually a p-type semiconductor and has the orthorhombic GeS-type layered crystal structure composed of an alternating stack of (Sn2+Se2–)2 layers along the a-axis. In contrast, a simple binary selenide PbSe has a cubic rock-salt (RS-) type structure. Different from SnSe, the RS-type structure is thermodynamically stable for PbSe at room temperature. Comparing these crystal structures, one expects that a smaller hole effective mass and a higher hole mobility would be realized if the crystal structure of SnSe is changed from the thermal equilibrium GeS-type one to the RS-type one because the three-dimensional network of high-coordination number polyhedra [sixfold (PbSe6) in the RS-type one] forms larger band dispersions than two-dimensional layered structures [threefold (SnSe3) in the GeS-type one]. As found in the SnSe–PbSe phase diagram, isovalent Pb2+ ions can substitute for part of the Sn2+ sites in the orthorhombic GeS-type SnSe at thermal equilibrium [63]. For example, at 400 K, ~20% Pb2+ can occupy the Sn2+ sites in the orthorhombic GeS-type structure, while more than 60% Pb2+ substitution is necessary to stabilize the RS-type structure in (Sn, Pb)Se. On the other hand, in the intermediate Pb concentration region between 20 and 60%, single-phase (Sn, Pb)Se is not obtained. Only a mixture of the GeS-type and the RS-type phases is obtained at a thermal equilibrium at 400 K. However, the RS-type (Sn, Pb)Se with smaller Pb concentrations down to ~40% is stabilized at higher temperatures (e.g., ~1100 K).

Recently, RS-type SnSe and (Sn, Pb)Se have gathered renewed attention because they are expected to be new topological insulators. So far, RS-type (Sn, Pb)Se single crystals are grown using a self-selecting vapor-growth method by a large amount of Pb doping to SnSe (63 and 77% Pb doping) [i.e., the chemical compositions are very Pb-rich, (Sn0.37Pb0.63)Se and (Sn0.23Pb0.77)Se.] Although a higher Sn concentration would provide a higher topological insulator transition temperature, the maximum Sn concentration is limited to 37%, corresponding to a minimum Pb concentration as high as 63% to stabilize the cubic RS-type structure in SnSe. From the phase diagram, the RS-type (Sn, Pb)Se composition region by freezing the high-temperature RS-type (Sn, Pb)Se phase may be extended.

Thus, isovalent Pb doping to the orthorhombic GeS-type SnSe in order to stabilize the nonequilibrium RS-type (Sn, Pb)Se phase was examined. Reactive solid-phase epitaxy [29], in which a thin RS-type PbSe epitaxial template layer works as a sacrificial layer (Fig. 10.14), was employed [64]. Additionally, a quenching process from 600 ℃ to RT also effectively stabilizes the nonequilibrium RS-type epitaxial (Sn, Pb)Se. Using this technique, we succeeded in varying the Pb concentration from 0 to 100%. The minimum Pb concentration to stabilize the RS-type SnSe is 50%, which is the lowest minimum Pb content ever reported. A structural transition from the GeS-type to the RS-type drastically increases the hole mobility from 60 for SnSe to 290 cm2 V−1 s−1 for 58% Pb-doped RS-type film, as expected. The p-type to n-type conversion is also observed upon further increasing the Pb doping up to 100% (i.e., the end member PbSe). A maximum electron mobility of 340 cm2 V−1 s−1 is achieved by 61% Pb doping.

Reprinted from ref. [64]. Copyright © 2016 American Chemical Society

Reactive solid-phase epitaxy for the (Sn1–x Pb x )S epitaxial films and their carrier transport properties at room temperature as a function of x. σ, N h,e, and μ Hall show the electrical conductivity, carrier concentration of hole or electron, and Hall mobility, respectively.

4 Modulation of Functional Nanolayers

State-of-the-art information storage devices such as USB flash drives are electronic data storage devices, which store digital information by electrical resistivity changes of semiconducting silicon using the electric field effect to process information into “words” consisting of various combinations of the numbers “0” and “1”. Since miniaturization technology has already reached its limit, epoch-making technology is strongly required to further improve the storage capacity.

We have demonstrated multi-information memory devices, which are composed of metal oxides showing both an electrical resistivity change and magnetism/color change simultaneously by a redox reaction of the metal oxides. Three-terminal thin-film transistor (TFT) structures were fabricated on a functional metal oxide using an insulating oxide, water-infiltrated calcium aluminate (C12A7) with mesoporous structure, as the gate insulator. We utilized H+/OH− ions in the water to change the valence state of the metal oxides by applying a gate voltage since H+/OH− ions are strong reducing/oxidizing agents for metal oxides. Upon changing the valence of the transition metal ion, the metal oxide changes from an insulator to a metal as well as from nonmagnetic to magnetic or from colorless transparent (invisible) to visible, as schematically illustrated in Fig. 10.15. Although the present device requires a relatively long storage time (a few seconds) because it utilizes mobile ion diffusion in the functional metal oxide, it has great merits. For example, it has nonvolatile operations, which mean no standby power is required after storing information. The present multi-information storage device should be useful for Internet of Things (IoT) technologies.

Schematic concept of a reversible conversion of optical-, electrical-, and magnetic properties of functional metal oxides using an electrochemical redox reaction of metal oxides with H+ and OH− of liquid water. For example, by combining the electrical properties and the optical properties, a novel electrochromic device, which can store A/B in addition to 0/1 for storing information, can be developed

As IoT technologies become more ubiquitous, the information gathered annually is rapidly increasing as various machines, as well as personal computers, are connected to the internet. State-of-the-art information storage devices such as USB flash drives are electronic data storage devices. They store digital information using an electrical resistivity change of semiconducting silicon and an electric field effect that process information into “words” consisting of various combinations of the numbers “0” and “1”. Although the storage capacity of such devices increased annually due to miniaturization techniques, the limit of such miniaturization techniques has already been reached. Consequently, complicated multi-levelization techniques such as “0”, “1”, “2”, and “3” are utilized to improve the storage capacity. To further improve the storage density, epoch-making technology is strongly required.

To overcome this obstacle, we proposed the following idea: utilizing functional materials whose optical transmittance or magnetism can be dramatically changed together with a change in the electrical resistivity. Such features would be very useful to improve the storage capacity. For example, multiple storing/reading of information becomes possible when vision and electrical signals are combined with displays. Such devices are appropriate for future IoT technologies. However, it is impossible to use optical transmittance or magnetic properties in case of semiconductor Si. In addition, it is impossible to use the electrical resistivity change in case of a magnetic metal.

Our research has focused on metal oxides because some metal oxides exhibit changes in their optical property or magnetic property together with the electrical property via an oxidation/reduction (redox) reaction. Generally, such redox reactions occur at a high temperature (several hundred degrees) heat treatment in an oxidizing or reducing atmosphere. However, this method is inappropriate for device operations. On the other hand, redox reactions using electrochemistry such chemical battery cells occur at room temperature. The latter technique is appropriate for practical applications, but the device must be sealed to prevent electrolyte leakage.

Unexpectedly, in 2010, Ohta et al. found that water, which is automatically absorbed into the mesoporous structure of an insulating oxide due to capillary action, can be a good electrolyte for this purpose [65]. Three-terminal thin-film transistor (TFT) structures were fabricated on a functional metal oxide using an insulating oxide, calcium aluminate (12CaO∙7Al2O3, C12A7) with mesoporous structure (namely CAN, calcium aluminate with nanopores) as the gate insulator (Fig. 10.16). C12A7 can be prepared by PLD at room temperature under a relatively high oxygen atmosphere of ~5 Pa. CAN films contain many mesopores (~10 nm in diameter) whose volume fraction is ~30% [65]. Temperature desorption spectra of the CAN film reveal that the mesopores are fully occupied with molecular water. The AC conductivity of the CAN film is ~10−9 S cm−1 at room temperature, [66] which is comparable to that of ultrapure water. Thus, water moisture in air is automatically absorbed in the mesopores of CAN film by capillary action.

Schematic illustration of CAN (calcium aluminate with nanopore) gated functional oxide thin-film transistor with a three-terminal electrodes geometry. Since 30 volume percent of the CAN film is occupied with liquid water, H+ and OH− ions in the CAN film move with a gate voltage application. The percolation AC conductivity is ~10−9 S cm−1, which is comparable to that of ultrapure water. Changing the valence of the transition metal ion by a gate voltage application changes the functional oxide from an insulator to a metal as well as from a nonmagnetic to a magnetic material or from colorless and transparent to a black color

In 2016, Katase and Ohta et al. utilized H+/OH− ions in a water-infiltrated CAN film to change the valence of the metal oxides by applying a gate voltage because H+/OH− ions are strong reducing/oxidizing agents for metal oxides. As the valence of the transition metal ion changes, the metal oxide changes from an insulator to a metal, a nonmagnetic to a magnetic material, or from transparent to a black color. Although the present device requires a relatively long storage time (a few seconds) since it utilizes mobile ion diffusion in the functional metal oxide, it has great merits. For example, it has nonvolatile operations, which mean no standby power is required after storing information. The present multi-information storage devices would be useful for IoT technologies.

The authors have developed two multi-information memory devices, which use a magnetic [67] or optical [68] signal along with an electronic signal to double the storage capacity in these “multiplex writing/reading” devices. In addition to the binary 0/1 method of storing information in a state-of-the-art memory device, the present devices can also store A/B for the information. More details for each type of memory device are provided below.

4.1 Utilizing Antiferromagnetic Insulator/Ferromagnetic Metal Conversion in SrCoO2.5+δ [67]

To realize “multiplex writing/reading” devices, material selection is the most information factor. Katase and Ohta et al. choose strontium cobaltite, SrCoO2.5+δ , for this purpose because SrCoO2.5 is an antiferromagnetic insulator and SrCoO3 is a ferromagnetic metal [69, 70]. The valence state of the cobalt ion in SrCoO2.5+δ can be controlled from 3 + (SrCoO2.5) to 4 + (SrCoO3) by changing the excess oxygen content (δ) from 0 to 0.5. Since the crystal structures of SrCoO2.5 (brownmillerite) and SrCoO3 (perovskite) are similar, the authors expected that the topotactic redox reaction between SrCoO2.5 and SrCoO3 can be controlled electrochemically. By utilizing this phenomenon for three-terminal thin-film transistors with water containing a mesoporous glass gate insulator, we developed a multi-information memory device. This device can be utilized not only to change the electrical resistivity (0/1) but also to change of magnetic property (A/B), as schematically shown in Fig. 10.17.

Reprinted with permission from [67]. © 2016 John Wiley and Sons

Principle of a multi-memory device using antiferromagnetic insulator/ferromagnetic metal conversion in SrCoO2.5+δ . This device would store both A/B and 0/1 information.

The three-terminal TFT device, which is composed of an epitaxial SrCoO2.5 film (30 nm, active channel material), an amorphous Na-Ta-O film with a mesoporous structure (300 nm, gate insulator), and an amorphous WO3 film (20 nm, proton absorber), was prepared by PLD on (001) SrTiO3 single-crystal substrate. It should be noted that we recently developed an amorphous Na-Ta-O film with a mesoporous structure, which can be used as an alkaline solution. When a negative gate voltage (−3 V) is applied between the gate and source electrodes, OH− ions, which are contained in the mesoporous glass, penetrate into SrCoO2.5+δ . Finally, SrCoO3 is formed in 3 s. On the contrary, a positive gate voltage (+3 V) application to the gate–source electrodes reduces SrCoO3 into SrCoO2.5 in 3 s [67].

Figure 10.18a shows a schematic of the device structure, which is similar to conventional three-terminal thin-film transistors. The channel (source–drain) length and width are 800 μm and 400 μm, respectively. The electrodes E1–E4 are used to measure the sheet resistance (R s). Figure 10.18b shows the changes in R s of the device. Before the device operation (state A), R s increases with decreasing temperature, indicating an insulating behavior. When a negative gate voltage (−3 V) is applied for 3 s (state B), R s decreases by three orders of magnitude and shows a metallic temperature dependence. After that, the device returns to the original state when a positive gate voltage (+3 V) is applied for 3 s. The device is reversibly operable (Fig. 10.18b, inset).

Reprinted with permission from [67]. © 2016 John Wiley and Sons

a Schematic device structure similar to conventional three-terminal thin-film transistors. b Temperature dependence of the sheet resistance of the device. a Virgin state, b after applying a negative Vg of −3 V, and c subsequent application of +3 V (dotted line). The inset shows the cyclability at RT in air. c m−T curves of the SrCoOx layer at states A−C in (b) measured under H = 20 Oe applied parallel to the in-plane direction. The inset shows a magnetic hysteresis loop at 10 K at states A and B.

Figure 10.18c shows the changes in the magnetic state of the device at states A, B, and C. At states A and C, the magnetic moment is zero, indicating that SrCoO2.5+δ (δ = 0) is an antiferromagnetic state. At state B, the device shows a ferromagnetic behavior with a Curie temperature of 275 K, indicating that SrCoO2.5+δ (δ ~ 0.5) is a ferromagnetic state. These results clearly demonstrate that both electrical resistivity and magnetism changes can be used in the present device.

4.2 Utilizing a Colorless Transparent Insulator/Dark Blue Metal Conversion in H x WO3 [68]

Katase and Ohta et al. [68] have also developed a new information display/storage device using a three-terminal thin-film transistor structure on an electrochromic material, which has been attracted attention as an “electric curtain”. The device shows a color change (colorless transparent/dark blue) together with an electrical conductivity change (insulator/metal) by applying a gate voltage. Since the device can be fabricated at room temperature, low cost fabrication is possible. Thus, larger area devices are easily fabricated. For example, the present device is applicable as an information display/storage on a window glass.

Protonation/deprotonation of tungsten trioxide (WO3), known as an electrochromic material, is converted reversibly from a colorless transparent insulator to a dark blue metal [71]. By utilizing this phenomenon in a three-terminal thin-film transistor with a water-containing mesoporous glass gate insulator, a multi-information memory device has been realized. This device can be utilized using not only a change in the electrical resistivity (0/1) but also a change in optical transmittance (A/B), as schematically shown in Fig. 10.19.

Reprinted from [68]. © 2016 NPG

Principle of a multi-memory device using a colorless transparent insulator (amorphous WO3)/dark blue metal (amorphous HWO3) conversion in H x WO3. This device would store both A/B and 0/1 information. This device should be suitable as a smart window or a smart mirror, which can display or store information. Furthermore, the present device can be used as an “electronic curtain” as the whole surface of window glass can be switched reversibly from colorless and transparent to dark blue.

The three-terminal TFT device composed of an amorphous WO3 film (100 nm, active channel material), a mesoporous CAN film (300 nm, gate insulator), a polycrystalline NiO film (50 nm, oxygen absorber), and amorphous ITO films (20 nm, gate, source, and drain electrodes) was prepared by PLD at room temperature on a glass substrate. When a positive gate voltage (a few volts) is applied between the gate and the source electrodes, H+ and OH− ions, which are contained in the mesoporous glass, diffuse to the WO3 and NiO sides, respectively, forming HWO3 and NiOOH. Since the resultant dark blue colored HWO3 shows a metallic electrical conductivity, the channel (drain–source) becomes electrically conductive. On the contrary, a negative gate voltage (a few volts) application to the gate–source electrodes results in HWO3 and NiOOH returning to WO3 and NiO, respectively. This conversion can be reversibly operated and the degree of change can be controlled by the applied gate voltage.

Figure 10.20a schematically depicts the device structure composed of a-WO3 (80 nm), CAN (300 nm), and NiO (20 nm)/ITO (20 nm) layers. Transparent ITO thin films are used for all the electrodes. All the films are deposited by PLD at room temperature. The device was fabricated on a transparent glass substrate (1 cm × 1 cm) as shown in Fig. 10.20b. The channel (source–drain) length and width are 800 μm and 400 μm, respectively. Note that the device is colorless and transparent. Figure 10.20c shows the changes in R s. When a positive gate voltage is applied to the device for 10 s, R s decreases by several orders of magnitude. The color becomes dark blue (Fig. 10.20d). The device reverts to the original state (transparent, insulator) when a negative gate voltage is applied for 10 s. The device is reversibly operable. Although the present device requires a relatively long storage time (a few seconds) since it utilizes mobile ion diffusion in the functional metal oxide, it has great merits. For example, it employs nonvolatile operation, which means standby power is not required after storing information. The present multi-information storage devices would be useful for IoT technologies.

Reprinted from [68]. © 2016 NPG

a Schematic device structure. b Transparent device on a glass substrate. c Repeatable switching of the sheet resistance. d Optical transmission spectra. Before the operation, the device is an insulator (R s ~ 108 Ω sq−1) and fully transparent in the visible light region. When a positive gate voltage is applied to the device for 10 s, R s decreases several orders of magnitude and the device becomes dark blue due to electrochemical protonation of WO3.

References

R. Eason, Pulsed Laser Deposition of Thin Films Applications-Led Growth of Functional Materials. (Wiley, Inc., UK, 2007)

R. Ramesh, D.G. Schlom, MRS Bull. 33, 1006 (2008)

H. Ohta, K. Sugiura, K. Koumoto, Inorg. Chem. 47, 8429 (2008)

J.W. Fergus, J. Eur. Ceram. Soc. 32, 525 (2012)

T. Okuda, K. Nakanishi, S. Miyasaka, Y. Tokura, Phys. Rev. B 63, 113104 (2001)

S. Ohta, T. Nomura, H. Ohta, K. Koumoto, J. Appl. Phys. 97, 034106 (2005)

H. Ohta, S. Kim, Y. Mune, T. Mizoguchi, K. Nomura, S. Ohta, T. Nomura, Y. Nakanishi, Y. Ikuhara, M. Hirano, H. Hosono, K. Koumoto, Nature Mater. 6, 129 (2007)

H. Ohta, T. Mizuno, S.J. Zheng, T. Kato, Y. Ikuhara, K. Abe, H. Kumomi, K. Nomura, H. Hosono, Adv. Mater. 24, 740 (2012)

W.S. Choi, H. Ohta, H.N. Lee, Adv. Mater. 26, 6701 (2014)

P. Delugas, A. Filippetti, M.J. Verstraete, I. Pallecchi, D. Marre, V. Fiorentini, Phys. Rev. B 88, 045310 (2013)

T.A. Cain, S. Lee, P. Moetakef, L. Balents, S. Stemmer, S.J. Allen, Appl. Phys. Lett. 100, 161601 (2012)

I. Pallecchi, F. Telesio, D.F. Li, A. Fete, S. Gariglio, J.M. Triscone, A. Filippetti, P. Delugas, V. Fiorentini, D. Marre, Nature Commun. 6, 6678 (2015)

S. Shimizu, S. Ono, T. Hatano, Y. Iwasa, Y. Tokura, Phys. Rev. B 92, 165304 (2015)

L.D. Hicks, M.S. Dresselhaus, Phys. Rev. B 47, 12727 (1993)

N.T. Hung, E.H. Hasdeo, A.R.T. Nugraha, M.S. Dresselhaus, R. Saito, Phys. Rev. Lett. 117, 036602 (2016)

C. Rodenbucher, M. Luysberg, A. Schwedt, V. Havel, F. Gunkel, J. Mayer, R. Waser, Sci Rep-Uk 6, 32250 (2016)

T. Tomio, H. Miki, H. Tabata, T. Kawai, S. Kawai, J. Appl. Phys. 76, 5886 (1994)

L.F. Mattheiss, Phys. Rev. B 6, 4718 (1972)

S.A. Turzhevsky, D.L. Novikov, V.A. Gubanov, A.J. Freeman, Phys. Rev. B 50, 3200 (1994)

D. Oka, Y. Hirose, S. Nakao, T. Fukumura, T. Hasegawa, Phys. Rev. B 92, 205102 (2015)

X.X. Xu, C. Randorn, P. Efstathiou, J.T.S. Irvine, Nature Mater. 11, 595 (2012)

Y. Zhang, B. Feng, H. Hayashi, T. Tohei, I. Tanaka, Y. Ikuhara, H. Ohta, J. Appl. Phys. 121, 185102 (2017)

R.D. Shannon, Acta Crystallogr. A 32, 751 (1976)

Y. Ishida, R. Eguchi, M. Matsunami, K. Horiba, M. Taguchi, A. Chainani, Y. Senba, H. Ohashi, H. Ohta, S. Shin, Phys. Rev. Lett. 100, 056401 (2008)

Y. Ikuhara, P. Pirouz, Microsc. Res. Tech. 40, 206 (1998)

P.K. Davies, J.Z. Tong, T. Negas, J. Am. Ceram. Soc. 80, 1727 (1997)

D.A. Muller, N. Nakagawa, A. Ohtomo, J.L. Grazul, H.Y. Hwang, Nature 430, 657 (2004)

C.L. Chen, Z.C. Wang, F. Lichtenberg, Y. Ikuhara, J.G. Bednorz, Nano Lett. 15, 6469 (2015)

H. Ohta, K. Nomura, M. Orita, M. Hirano, K. Ueda, T. Suzuki, Y. Ikuhara, H. Hosono, Adv. Funct. Mater. 13, 139 (2003)

H. Ohta, H. Mizoguchi, M. Hirano, S. Narushima, T. Kamiya, H. Hosono, Appl. Phys. Lett. 82, 823 (2003)

H. Hiramatsu, K. Ueda, H. Ohta, M. Orita, M. Hirano, H. Hosono, Appl. Phys. Lett. 81, 598 (2002)

H. Ohta, S.W. Kim, S. Ohta, K. Koumoto, M. Hirano, H. Hosono, Cryst. Growth Des. 5, 25 (2005)

K. Mizushima, P.C. Jones, P.J. Wiseman, J.B. Goodenough, Mater. Res. Bull. 15, 783 (1980)

T. Ohzuku, A. Ueda, J. Electrochem. Soc. 141, 2972 (1994)

I. Terasaki, Y. Sasago, K. Uchinokura, Phys. Rev. B 56, 12685 (1997)

M. Lee, L. Viciu, L. Li, Y.Y. Wang, M.L. Foo, S. Watauchi, R.A. Pascal, R.J. Cava, N.P. Ong, Nature Mater. 5, 537 (2006)

K. Takada, H. Sakurai, E. Takayama-Muromachi, F. Izumi, R.A. Dilanian, T. Sasaki, Nature 422, 53 (2003)

R.E. Schaak, T. Klimczuk, M.L. Foo, R.J. Cava, Nature 424, 527 (2003)

X.H. Ma, H.L. Chen, G. Ceder, J. Electrochem. Soc. 158, A1307 (2011)

J. Billaud, R.J. Clement, A.R. Armstrong, J. Canales-Vazquez, P. Rozier, C.P. Grey, P.G. Bruce, J. Am. Chem. Soc. 136, 17243 (2014)

J. Billaud, G. Singh, A.R. Armstrong, E. Gonzalo, V. Roddatis, M. Armand, T. Rojob, P.G. Bruce, Energy Environ. Sci. 7, 1387 (2014)

R.O. Jean-Paul Parant, M. Devalette, C. Fouassier, P. Hagenmuller, J. Solid State Chem. 3, 1 (1971)

A. Caballero, L. Hernan, J. Morales, L. Sanchez, J.S. Pena, M.A.G. Aranda, J. Mater. Chem. 12, 1142 (2002)

S. Hirano, R. Narita, S. Naka, J. Cryst. Growth 54, 595 (1981)

S. Katayama, T. Katase, T. Tohei, B. Feng, Y. Ikuhara, H. Ohta, Cryst. Growth Des. 17, 1849 (2017)

K. Zaghib, M. Simoneau, M. Armand, M. Gauthier, J. Pow. Sources 81, 300 (1999)

G.X. Wang, D.H. Bradhurst, S.X. Dou, H.K. Liu, J. Pow. Sources 83, 156 (1999)

F. Ronci, P. Reale, B. Scrosati, S. Panero, V.R. Albertini, P. Perfetti, M. Di Michiel, J.M. Merino, J. Phys. Chem. B 106, 3082 (2002)

S. Scharner, W. Weppner, P. Schmid-Beurmann, J. Electrochem. Soc. 146, 857 (1999)

M. Kitta, T. Akita, Y. Maeda, M. Kohyama, Langmuir 28, 12384 (2012)

K.M. Colbow, J.R. Dahn, R.R. Haering, J. Pow. Sources 26, 397 (1989)

M. Hirayama, K. Kim, T. Toujigamori, W. Cho, R. Kanno, Dalton T 40, 2882 (2011)

A. Kumatani, T. Ohsawa, R. Shimizu, Y. Takagi, S. Shiraki, T. Hitosugi, Appl. Phys. Lett. 101 (2012)

N. Li, T. Katase, Y. Zhu, T. Matsumoto, T. Umemura, Y. Ikuhara, H. Ohta, Appl. Phys. Express 9 (2016)

J.K. Burdett, T. Hughbanks, G.J. Miller, J.W. Richardson, J.V. Smith, J. Am. Chem. Soc. 109, 3639 (1987)

S. Pandey, H. Kontani, D.S. Hirashima, R. Arita, H. Aoki, Phys. Rev. B 86 (2012)

K. Sasmal, B. Lv, B. Lorenz, A.M. Guloy, F. Chen, Y.Y. Xue, C.W. Chu, Phys. Rev. Lett. 101 (2008)

T. Kimura, Y. Otani, T. Sato, S. Takahashi, S. Maekawa, Phys. Rev. Lett. 98 (2007)

N.P. Stern, S. Ghosh, G. Xiang, M. Zhu, N. Samarth, D.D. Awschalom, Phys. Rev. Lett. 97 (2006)

T. Sato, K. Nakayama, Y. Sekiba, P. Richard, Y. M. Xu, S. Souma, T. Takahashi, G.F. Chen, J.L. Luo, N.L. Wang, H. Ding, Phys. Rev. Lett. 103 (2009)

H. Hiramatsu, S. Matsuda, H. Sato, T. Kamiya, H. Hosono, Acs Appl. Mater. Inter. 6, 14293 (2014)

T. Hatakeyama, H. Sato, H. Hiramatsu, T. Kamiya, H. Hosono, Appl. Phys. Express 9 (2016)

A.A. Volykhov, V.I. Shtanov, L.V. Yashina, Inorg. Mater. 44, 345 (2008)

T. Inoue, H. Hiramatsu, H. Hosono, T. Kamiya, Chem. Mater. 28, 2278 (2016)

H. Ohta, Y. Sato, T. Kato, S. Kim, K. Nomura, Y. Ikuhara, H. Hosono, Nature Commun. 1, 118 (2010)

H. Ohta, J. Mater. Sci. 48, 2797 (2013)

T. Katase, Y. Suzuki, H. Ohta, Adv. Electron. Mater. 2 (2016)

T. Katase, T. Onozato, M. Hirono, T. Mizuno, H. Ohta, Sci. Rep-UK 6 (2016)

H. Taguchi, M. Shimada, M. Koizumi, J. Solid State Chem. 29, 221 (1979)

Y. Takeda, R. Kanno, T. Takada, O. Yamamoto, M. Takano, Y. Bando, Z. Anorg. Allg. Chem. 541, 259 (1986)

C.G. Granqvist, Sol. Energy Mater. Sol. Cells 60, 201 (2000)

Acknowledgements

The authors would like to thank Prof. T. Katase (Tokyo Tech.), Dr. N. Li, Dr. S. Katayama, Mr. Y. Zhang, Prof. T. Kamiya (Tokyo Tech.), and Prof. H. Hosono (Tokyo Tech.) for the valuable discussions and experimental assistance. This work was supported by a Grant-in-Aid for Scientific Research on Innovative Areas (25106007). H. Ohta was also supported by the Asahi Glass Foundation. H. Hiramatsu was also supported by Support for TokyoTech Advanced Research (STAR).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2018 The Author(s)

About this chapter

Cite this chapter

Ohta, H., Hiramatsu, H. (2018). Fabrication, Characterization, and Modulation of Functional Nanolayers. In: Tanaka, I. (eds) Nanoinformatics. Springer, Singapore. https://doi.org/10.1007/978-981-10-7617-6_10

Download citation

DOI: https://doi.org/10.1007/978-981-10-7617-6_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7616-9

Online ISBN: 978-981-10-7617-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)