Abstract

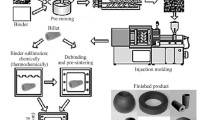

Ceramic injection moulding is normally performed in conventional moulding machines. The machine parts subject to wear are made of wear resistant alloys in order to achieve acceptable machine life. Even so, the worn off material is enough to contaminate the ceramic compound and generate critical defects in the ceramic end product. Such contamination will limit the strength and reliability of ceramic products.

Defects caused by worn off material were virtually eliminated by substituting the steel parts of mixing and moulding machines in contact with the moulded material with ceramic parts. The screw, cylinder, valve and sprue bushing were made of silicon nitride and the inlet parts of polymer materials.

The design of the machine is described. An evaluation of the machine was made by comparing tensile test results of moulded rods from the conven tional machine and the ceramized machine.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Larker, H. T. and Karlsson, E., Glass Encapsulated HIP — A Production Reality, 5th International Fine Ceramics Workshop, March 15-16, 1990, Nagoya, Japan.

Nilsson, J. and Mattsson, B., A New Tensile Test Method for Ceramic Materials, Ceramic Materials and Components for Engines, ed. W. Bunk and H. Hausner, Deutsche Keramische Gesellschaft, Bad Honnef, 1986, pp. 651–6.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1992 Elsevier Science Publishers Ltd and MPA Stuttgart

About this chapter

Cite this chapter

Nilsson, J.O.H., Larker, H.T. (1992). Ceramized Injection Moulding Machine for Contamination Free Preforming. In: Carlsson, R., Johansson, T., Kahlman, L. (eds) 4th International Symposium on Ceramic Materials and Components for Engines. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-2882-7_60

Download citation

DOI: https://doi.org/10.1007/978-94-011-2882-7_60

Publisher Name: Springer, Dordrecht

Print ISBN: 978-1-85166-776-5

Online ISBN: 978-94-011-2882-7

eBook Packages: Springer Book Archive