Abstract

The waste products of zinc hydrometallurgy fall into two categories:

-

Ferric waste

-

Toxic waste

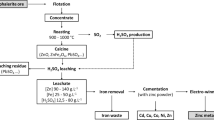

The first of these, produced by leaching the roasted zinc, is based on jarosite, goethite or haematite depending on the process followed.

The second kind, toxic waste, arises from the purification of neutral leaching solutions, and consists of zinc powder and various cemented metals (copper, cadmium, cobalt, nickel, among others).

In this paper, two laboratory-developed methods based on the technique of solvent extraction are presented and discussed.

The ferric waste is treated by a conventional hot acid leaching process; the acid ferric leach is treated with an amine solution, and subsequently the extracted iron is precipitated directly in the organic phase. The ferric hydroxide is calcinated, and a high-quality iron oxide with 70% iron is obtained.

On the other hand, in the case of the residue from purification, it undergoes mixed leaching, in the presence of an organic phase and another aqueous one in an oxidising atmosphere at room temperature.

The zinc is recovered through stripping of the organic phase, and the metals remaining in the aqueous phase are recovered through selective extraction or through precipitation. Lead and silver are left in the leaching residue.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Sitges F.and Arregui V. (1964) Patente Española n° 304.601

André J.A. and Dalvaux R.J. (1970) Production of Electrolytic Zinc at the Balen Plant of S.A. Vieille Montagne. World Symposium on Mining & Metallurgy of Lead & Zinc. AIME. (St.Louis. Missouri. USA)

De Juan D. (1973) Patente Española n°412.670

Rastas J.R., Huggare T.L.J, and Fugleberg S.P. (1973) Finland Patent n°A10/73

Möller D.J.and Wiegand V. (1979) Utilization of Electrolytic Zinc Plant Residues. Lurgi Information 1979

Arregui V., Gordon A.R. and Steintveit G. (1980) The Jarosita Process: Past, Present and Future. Symposium on Metallurgy & Environmental Control. AIME

Steintveit G. (1970) Electrolytic Zinc Plant and Residue Recovering. Det Norske Zinkkompani A/S. World Symposium on Mining & Metallurgy of Lead & Zinc. AIME. (St.Louis. Missouri. USA)

Schmidt. (1970) Cadmium Production at the Rühr-Zinc GmbH at Datteln. Erzmetall (Germany)

De Juan D. and Del Valle J.L. (1980) Un nuevo método para la recuperatión del cadmio en las plantas de cine electrolítico. IV Congreso Internacional de Minería y Metalurgia. (Huelva-España)

U.S. EPA. Standars applicable to owners and operators of hazardous waste treatment, storage and disposal facilities. Code of Federal Regulations, Tittle 40, Parts 260–267

Piret N.L. and Castle J.F. (1990) Review of Secondary Zinc Treatment Process Option. Symposium on Recycling of Metalliferous Materials. IMM

Selke A. and De Juan D. (1989) Zinc Recovery by Solvent Extraction. International Symposium on Production and Technology in the Metallurgy Industries. (Kohln. Germany)

De Juan D. and Del Valle J.L. (1988) El proyecto Excinreside la ilusión a la realidad. VIII Congreso Internacional de Minería y Metalurgia. (Oviedo-España)

Collier D., Heng R., Lehman R. and Pietsch H.B. (1986) The Versatic Acid Process Solution to the Iron Problem in the Zinc Industry?. Symposium on Iron Control in Hydrometallurgy. IMM. (Toronto-Canada)

De Juan D., De Juan J. and Lozano L.J. (1992) Empleo del par Primene 81R/Fe (III) para la obtención de óxidos de hierro. Revista de Metalurgia. (Madrid-España).28(2), 1992, pp. 98–111

De Juan D. (1966) Determinatión polarográfica arbitral de cobre y cadmio. Revista de Metalurgia. (Madrid-España). 1966, pp. 283–285

Perales A. (1993) Estudio técnico-económico de un método de tratamiento no contaminante de los residuos de purificación en la hidrometalurgia del cine. Tesis Doctoral. Universidad de Murcia.

Thorsen G. U.S.Patent n° 4.008.134. Britain Patent n° 1.474.944

Comision de quimicos de la industria minera y metalurgica alemana. (1956) Métodos de análisis de control industrial. Ed. Aguilar (mMadrid-España)

De Juan D. (1971) Análisis de constituyentes en productos metalúrgicos no férreos por espectrofotometría de absorción atómica. Informatión de Química Analítica. (Madrid-España). 1971, pp. 55–62

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 1994 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Juan, D., Perales, A. (1994). Ecological treatment of waste products from zinc hydrometallurgy. In: Hydrometallurgy ’94. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-1214-7_77

Download citation

DOI: https://doi.org/10.1007/978-94-011-1214-7_77

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-4532-2

Online ISBN: 978-94-011-1214-7

eBook Packages: Springer Book Archive