Abstract

Plants have been used as a source for many pharmaceutical since long. However, utilization of plant systems for production of edible vaccines has been a comparatively recent phenomenon. There are several potential advantages of plant derived vaccines over other conventional systems of vaccine production such as mammalian or avian cell culture. The cost of vaccines is one factor preventing further use of vaccination, leaving hundreds of thousands of children susceptible to preventable diseases. Especially for developing world this novel technique proved to be a boon for its low cost of production, convenient administration, easy storage and negligible chances of infection whereas the conventional system of vaccine production limits the applicability of vaccines in many parts of the world. These vaccines are prepared by introducing selected desired genes into plants and inducing these genetically modified plants to manufacture the encoded proteins. Transgenic plants may provide an ideal expression system, in which transgenic plant material can be fed directly as oral dose of recombinant vaccines. Expression of vaccines in plant tissue eliminates the risk of contamination with animal pathogen, provides a heat stable environment and enables oral delivery thus eliminating infection related hazards. Identification of transgenic material, containment of the transgenes and control of recombinant protein may be potential problems for large scale production of vaccines in plants. Factors like scaling up production as well as distribution and handling of transgenic plant material must comprise the future consideration in this field.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

10.1 Introduction

Since time immemorial, plants besides providing food and shelter have also been used for basic preventive and curative health care by human beings. Plants were the first and only source for every kind of medication in primitive times. Gradually, animal derived products were also started being used as medicines for some ailments like snake venom has been used for medical purposes for thousands of years. In Chinese medicine snake skin was used to treat superficial diseases, including skin eruptions, eye infections or opacities, sore throat, and hemorrhoids. However, plants still remained to be the primary source of medication till now for their ease of availability and safe nature.

With the advent of modern science and technology, pharmacology has shown remarkable advances with the artificial production of plant and animal based medicines in laboratories. Apart from this some novel medicinal compounds were also synthesized to combat life threatening diseases. All these advancements were aimed to increase average human life span and to decrease the child mortality rate. A significant step taken in this regard was the Universal Immunization Programme (UIP) launched by WHO in 1980s in which children all over the world are vaccinated against six deadly diseases (BCG, OPV, diphtheria, tetanus, pertussis, and measles) with the aim of immunizing 80 % of all children by 1990. However, even after all these efforts 20 % of infants are still left unimmunized; responsible for approximately two million unnecessary deaths every year, especially in remote and impoverished parts of the globe (Langridge 2006). Moreover, immunization remains an unfinished agenda with an estimated 19.3 million children were not reached with three doses of DTP vaccine in 2010. Those who are not immunized – about every Fifth Child – are mostly among the poorest and the most vulnerable.

Vaccination is an important tool for prevention of many diseases. It is the administration of vaccine to produce immunity to a disease. Vaccination involves the stimulation of the immune system to prepare it for the event of an invasion from a particular pathogen for which the immune system has been primed (Arntzen 1997). On recognizing the foreign substance (live/ weakened microbes, antigen or proteins) which enters the body through vaccine, the immune system activates, producing antibodies to destroy the invader. Not only this but this attack leaves behind the ‘memory’ T and B cells which guards body in case of any future attack by that pathogen. Some vaccines provide lifelong protection; others (such as those for cholera and tetanus) must be re-administered periodically (Langridge 2006). Classically, this has been achieved by presenting the immune system with whole viruses or bacteria that have been killed or made too weak to proliferate much. However, these conventional vaccines poses threat of actually acquiring the infection from weakened or attenuated pathogenic strains. Thus newer approach uses sub unit vaccines and recombinant vaccines. These vaccines consist of specific macromolecules that induce a protective immune response against a pathogen rather than administering the whole pathogen in the body. A “subunit vaccine” refers to a pathogen-derived protein (or even just an immunogenic domain of a protein, i.e. “an epitope”) that cannot cause disease but can elicit a protective immune response against the pathogen. Very often the subunit-vaccine candidate is a recombinant protein made in transgenic production-hosts (such as cultured yeast cells), then purified, and injected as vaccines to immunize against a specific disease (Mor and Arntzen 2002). These sub-unit vaccines increases vaccine safety by circumventing the need to use live viruses or microbes and has thus made them the preferred approach for vaccine manufacturers (National Institute of Allergy and Infectious Diseases 1998).

Unfortunately, traditional subunit vaccines are expensive to produce and not heat stable which limits their availability and use in developing countries. Although these vaccines have an undue advantage over traditional conventional vaccines but they are expensive and their storage and transportation pose a problem as many of them require refrigeration. This is a disadvantage in many of the developing countries where the vaccines were needed most. Thus, to ensure a successful global immunization a whole new idea of plant edible vaccines was presented by Arntzen and co-workers in 1992, by introducing the concept of transgenic plants as a production and delivery system for subunit vaccines (Mason et al. 1992; Mason and Arntzen 1995). They envisaged that production would be as cheap as agriculture, that distribution would be as convenient as marketing fresh produce and that administration would be as simple and safe as eating (Mor et al. 1998).

10.2 Concept of Plant Edible Vaccines

Plants have long been considered an ideal expression system for many of the animal derived proteins, antibodies and pharmacologically important compounds. Factors in favor of plant systems as sources of animal derived proteins include: the potential for large-scale, low-cost biomass production using agriculture; the low risk of product contamination by mammalian viruses, blood borne pathogens, oncogenes and bacterial toxins; the capacity of plant cells to correctly fold and assemble multimeric proteins; low downstream processing requirements for proteins administered orally in plant food or feed; the ability to introduce new or multiple transgenes by sexual crossing of plants; and the avoidance of ethical problems associated with transgenic animals and the use of animal materials (Doran 2000). The first pharmaceutically relevant protein made in plants was human growth hormone, which was expressed in transgenic tobacco in 1986 (Barta et al. 1986). Since then, many other human proteins have been produced in an increasingly diverse range of crops. In 1989, the first antibody was expressed in tobacco (Hiatt et al. 1992).

The idea of suitability of plants as vaccine production and delivery system was presented by research group of Charles Arntzen in 1990s. This idea was quite promising in terms of providing a successful tool for mass immunization in developing countries where till now vaccination is hampered by high cost of production and delivery of vaccines. Basic concept of edible vaccines involves the production of plants containing antigens required to stimulate the immune response in human body. Thus by simply eating the plant product people will get vaccination against diseases. However the concept sounds quite simple but its development was equally complex. To produce edible vaccine, plants are engineered to contain desired gene of interest which codes for the antigen. This process is accomplished by transformation and the altered plant containing foreign gene is called transgenic plant. Thus, the process remains the same as with subunit vaccine preparation because it contains only desired antigen and not the whole pathogen. These vaccines basically work in the same way as the injected DNA vaccine, since a peptide sequence similar to an infectious part of a pathogen is synthesized, by itself, and is used to prime T and B cells in the body. The big difference in this case is that the protein sequences are encoded in a plant to form the desired protein. This protein is then ingested, as the plant or its fruit is eaten. One becomes immune against the ingested protein, as T and B cells become stimulated to proliferate and differentiate (Mor et al. 1998). Expression of vaccines in plant tissues eliminates the risk of contamination with animal pathogens, provides a heat-stable environment, and enables oral delivery, thus eliminating injection-related hazards (Walmsley and Arntzen 2000).

For production of edible vaccines, it is desirable to select a plant whose products are consumed raw to avoid degradation during cooking. Thus, plants like tomato, banana and cucumbers are generally the plants of choice. Vaccines made from plant material have enormous potential for use, in the developing world. Also it may be much easier to persuade people to eat protective vegetables than to accept injections or take pills. Vaccines made from mashed potato, designed to protect against travellers’ diarrhoea, have already been tested in humans. Vaccines made from dried tomatoes have also been developed. Both have been developed by the Cambridge-UK-based biotechnology company Axis Genetics, who pioneered the techniques involved.

10.3 Mechanism of Action

Edible vaccines are mucosal-targeted vaccines that stimulate both the systematic and mucosal immune network, activating the first line of defense of human body through mucosa. The mucosal surfaces are found lining the digestive tract, respiratory tract and urinoreproductive tract. Mucosal immune system (MIS) is the first line of defense and the most effective site of vaccination, nasal and oral vaccines being the most effective (Mor et al. 1998; Korban et al. 2002). Before understanding the mechanism of action of edible vaccines it is important to understand the functioning of MIS. Induction of a mucosal immune response starts with the recognition of an antigen by specialized cells called M-cells. These cells are localized in the mucosal membranes of lymphoid tissues such as Peyer’s patches within the small intestines. The M-cells channel the antigen to underlying tissues where antigen-presenting cells internalize and process the antigen. The resulting antigenic epitopes are presented on the APC surface, and with the assistance of helper T cells activate B cells. The activated B cells migrate to the mesenteric lymph nodes where they mature into plasma cells and migrate to mucosal membranes to secrete immunoglobulin (Ig) A. On passing through the mucosal epithelial layer towards the lumen, the IgA molecules complex with membrane-bound secretary components to form secretary IgA (sIgA). Transported into the lumen, the sIgA interacts with specific antigenic epitopes and neutralize the invading pathogen (Walmsley and Arntzen 2000). When edible vaccines are eaten they degrade majority of the plant cells in the intestine as a result of the action of digestive and bacterial enzymes. This degradation results in the release of antigens present in the plant product. The whole process occurs near the Peyer’s patches (Rudzik et al. 1975) where M cells recognize the released antigen and lead to the production of IgA antibodies in mucosal lymphoid tissues through the above mentioned mechanism. These IgA antibodies get transported across the epithelial cells into the lumen where they interact with released antigens depicting immunogenic response.

10.4 Preparation of Edible Vaccines

Plant edible vaccines are basically prepared using two strategies. Either through the introduction of antigen producing gene in plant genome via Agrobacterium species; the process known as transformation. This can also be done by directly inserting the target gene in plant genome without the help of any vector. In this case gene gun eliminates the requirement of vector by directly bombarding the target gene in plant tissue, through the technique known as bolistic method. Second strategy involves the use of plant viruses as vectors which results in transient expression of the foreign gene. The effect of the added genes is to make the plant or plant virus produce antigens which are normally found only on the surfaces of the pathogen. However, both the techniques require introduction of genes taken from the pathogenic microbe that infect humans but transformation technique offers certain advantages.

10.4.1 Transformation

There are three types of plant transformation methods:

-

1.

Agrobacterium mediated transformation

-

2.

Micro projectile bombardment/Bolistics method

-

3.

Electroporation

First method involves the use of Agrobacterium tumefaciens as a carrier or vector system for introduction of antigen producing gene in plant genome. Agrobacterium tumefaciens is a soil bacterium responsible for producing crown gall tumor in plants via its Ti (tumor inducing) plasmid. A. tumefaciens and A. rhizogenes has the property to integrate their plasmid DNA with nuclear genome of host (plants) cells. This property is exploited for introducing foreign gene in plants and the process is called ‘transformation’ while the plants produced through this process are ‘transgenic plants’. During transformation the bacterial plasmid is first disarmed by removing tumor inducing gene and the target gene for a selected immunogen is introduced. Along with the target gene, antibiotic resistance genes were also added in the plasmid which acts as marker genes to identify the transformed plant tissues containing bacterial plasmid. The bacterium is then co cultivated with the wounded plant tissues so that the bacterial DNA penetrate the plant cells. Following this the target gene randomly incorporates in the plant nuclear genome. After selection through antibiotic resistance successfully transformed plant tissues are identified and regenerated into whole plants under in vitro conditions. These transformed plant lines show varying degree of expression for introduced gene thus producing varying amount of desired antigen (Shah et al. 2011). Plant line showing highest expression is identified and propagated on large scale to be used as edible vaccine. The drawback of this method is that it gives low yield and the process is slow. It requires about 6 weeks to18 months for whole plants to be formed through this process depending on regeneration ability of various plant species under in vitro conditions. This method is more successful in dicotyledonous plants like potato, tomato and tobacco which are easy to transform through Agrobacterium in comparison to monocotyledons.

Second technique is capable of directly introducing the gene in plant cells through gene gun. This method is called ‘Bolistic method’. In this method selected DNA sequences are precipitated onto metal microparticles and bombarded against the plant tissue with a particle gun at an accelerated speed. Microparticles penetrate the walls and release the exogenous DNA inside the cell where it will be integrated in the nuclear genome through mechanisms that have yet to be clearly understood (Mishra et al. 2008). This method is quite attractive because DNA can be delivered into cells of plant which makes gene transfer independent of regeneration ability of the species. But the chief limitation is the need for costly device particle gun (Shah et al. 2011).

In another technique called ‘Electroporation’, DNA is introduced into cells by exposing them for brief period to high voltage electrical pulse which is thought to induce transient pores in the plasma lemma (Singh 2002). The cell wall presents an effective barrier to DNA, therefore, it has to be weakened by mild enzymatic treatment so as to allow the entry of DNA into cell cytoplasm.

Transformation technique results in stable expression of the foreign gene allowing production of subsequent generations of large numbers of transgenic plants, either by vegetative or sexual means. The seeds collected from these transgenic lines could be stored, and used as and when necessary for the molecular farming (Malabadi et al. 2012). It also provides the opportunity to introduce more than one gene for possible multi-component vaccine production. In addition, judicious choice of genetic regulatory elements allows organ and tissue-specific expression of foreign antigens (Mason and Arntzen 1995). Furthermore, plant DNA is not known to interact with the animal DNA and plant viral recombinants do not invade mammalian cells (Sala et al. 2003).

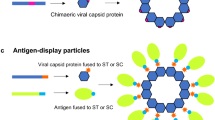

10.4.2 Chimeric Plant Virus Expression Systems

Another approach of plant edible vaccine production utilizes plant viral expression systems which addresses the low yield issue of transformation approach. The rationale of this approach is based on the notion that during viral replication, gene copy number becomes amplified, resulting in a much higher level of transgene expression than observed with stable transformation. Among the potential advantages of transient viral expression of transgenes over stably transformed transgenic plants are the shorter time for cloning of foreign genes in the viral genome as compared with the time required to transform plants, the ease at which antigen production can be scaled up, and the wide host range of plant viruses that allows the use of multiple plant species as biofactories (Koprowski and Yushibov 2001). Capsid proteins of many types of viruses can assemble into virus-like particles (VLPs). Devoid of the viral genetic material, VLPs often resemble the native virions in their morphology, antigenic properties and stability. These VLPs are genetically engineered to express the desired peptides/proteins.

Two techniques namely ‘Overcoat technology’ and ‘Epicoat technology’ are used to design VLPs that contain antigen DNA on their surface. Some plant viruses like CPMV (cowpea mosaic virus), alfalfa mosaic virus, TMV (tobacco mosaic virus), CaMV (cauliflower mosaic virus), Potato virus X and tomato bushy stunt virus can be used effectively for this purpose. Overcoat technology permits the plant to produce the entire protein, whereas epicoat technology involves the expression of only foreign protein (Lal et al. 2007). The recombinant virus is then inoculated into the host plant which produces several antigenic proteins (Mor et al. 1998). These particulate antigens generally elicit stronger mucosal immune responses than soluble antigens, which can often repress the immune response by inducing immunotolerance (Garside and Mowat 1997). However, each single antigen expressed in plants must be tested for its proper assembly and can be verified by animal studies, Western blot; and quantified by enzyme-linked immunosorbent assay (ELISA) (Haq et al. 1995). This method offers rapid onset of expression, and the systemic spread of virus so that protein is produced in every cell (Desai et al. 2010). VLPs are therefore predicted to make excellent mucosal vaccines (Estes et al. 1997).

However, the method poses certain limitations such as transient expression is less easy to initiate. Also the subsequent plant generations do not inherit the foreign gene as it is not incorporated into the plant genome. Thus the production of a plant virus-derived vaccinogen requires an extra step of inoculation of the host plants with the chimeric virus. Before administration, chimeric virus particles are often purified from host-plant tissues that are unpalatable, containing toxins or are not practical for direct consumption. Nevertheless, the high level of foreign protein expression (up to 2 g/kg of plant tissue) within a short period (1–2 weeks after inoculation) makes this an attractive alternative for vaccine production (Walmsley and Arntzen 2000).

Plants and plant viruses were not used until 1993, however, when an epitope from the foot-and-mouth disease virus (FMDV) was expressed on the surface of cowpea mosaic virus (CPMV) (Usha et al. 1993). Chimeric plant viruses were proven effective as carrier proteins for vaccinogens in 1994 after rabbits raised an immune response against purified chimeric CPMV particles expressing epitopes derived from human rhinovirus (Valenzuelz et al. 1985). Majorly TMV and CPMV were used initially as plant viral expression systems because of advantages of high yield (l–2 g of virus per kg of host tissue), thermostability and ease of virus purification, but now a days other plant viruses like alfalfa mosaic virus (AMV), CaMV (cauliflower mosaic virus) etc. are also being used. An increased interest in using plant virus vectors was witnessed for development of vaccines against many animal and human diseases (Adams et al. 1987; Clarke et al. 1990; Dedieu et al. 1992; Mastico et al. 1993; Lomonossoff and Johnson 1995).

10.5 Need and Advantages of Plant Edible Vaccines

In 1992, WHO estimated that three to five million children’s lives could be saved each year if new vaccines were available to control or prevent commonly occurring infectious diseases. CVI emphasized on the need to create technologies that would make vaccine cheap and more reliable, especially for the developing world. CVI (Children’s vaccine initiative) also presented idea of needle free immunization to save millions of children from the pain of needles and to avoid risk of death due to needle carried infections. The attention was laid on oral vaccines as they fulfill all the requirements and are an effective means of vaccination by activating the mucosal immunity where most of the pathogens attack first. Development of heat stable oral vaccines were demanded which could serve the purpose of mass immunization in developing countries. Being heat stable they can eliminate the requirement of cold chains which are very costly and generally not found those parts where vaccination is needed most.

Subunit vaccines based upon recombinant cell culture expression systems are feasible but, for commercial- scale production, these systems require fermentation technology and stringent purification protocols so that sufficient amounts of recombinant protein can be obtained for oral delivery. Even with technological improvements, fermentation-based subunit vaccine production may be a prohibitively expensive technology for developing countries where novel oral vaccines are urgently needed (Mason and Arntzen 1995). Plant derived edible vaccines are the answer to all these requirements. These vaccines offer all those advantages which make them an ideal candidate to create a disease free world. Following are the advantages of plant edible vaccines:

-

(a)

Plant derived edible vaccines are cheap as they eliminate the expenses associated with fermenters, purification, adjuvant, cold chain logistics, storage/transportation, needle free-administration, and sterile delivery (Davoodi-Semiromi et al. 2009, 2010; Walmsley and Arntzen 2003; Pascual 2007; Malabadi 2008; Daniell et al. 2009; Gomez et al. 2010).

-

(b)

Plant derived vaccine offer higher safety because they are needle/syringe free that is why risk of infections occurring from syringes is eliminated.

-

(c)

These vaccines do not require trained medical personnels for its administration unlike conventional vaccines which uses syringes as delivery system

-

(d)

Plant derived vaccines are safe and have less chances of contamination with human and animal pathogenic microorganisms, because plants are not hosts for human infectious agents (Giddings et al. 2000; Ma et al. 2004).

-

(e)

As edible vaccine can be administered orally, they elicit both mucosal and systemic immunity which is not observed in traditional vaccines.

-

(f)

These vaccines are heat stable and can be stored at room temperature, unlike traditional vaccine which need cold chain storage which increases the yearly cost to preserve vaccines and limits their availability to areas having cold storage facility (Nochi et al. 2007)

-

(g)

A concern with oral vaccines is the degradation of protein components in the stomach (due to low pH and gastric enzymes) and gut before they can elicit immune responses (Daniell et al. 2001b) but in plant edible vaccines bioencapsulation of antigen in the rigid plant cell walls could provide protection from intestinal degradation (Webster et al. 2002).

-

(h)

For production of edible vaccines, costly equipments and machines are not necessary as they could be easily grown in farms as compared to cell culture grown in fermenters.

-

(i)

Plant derived vaccines can be designed to contain numerous antigens for various disease. These multicomponent vaccines are called second generation vaccines and provide immunization against many diseases in a single dose.

-

(j)

An edible vaccine provides higher safety of individual as compared to traditional vaccine as edible vaccines are subunit preparation and do not involve attenuated pathogens which sometimes causes disease when administered as vaccine.

-

(k)

They can be ingested by eating the plant/part of the plant. So, the need to process and purify does not arise.

-

(l)

If the local/native crop of a particular area is engineered to produce the vaccine, then the need for transportation and distribution can be eliminated.

-

(m)

Plant cells are suitable for vaccine production due to their capability to correctly fold and assemble, not only antibody fragments and single chain peptides, but also full-length multimeric proteins.

-

(n)

Low downstream processing requirements for proteins administered orally.

-

(o)

As the antigen is present in edible plant product and can be administered by directly eating the plant tissue, it surpasses the purification requirement which otherwise is a costly process.

-

(p)

New or multiple transgenes can be introduced by sexual crossing of plants thus creating novel vaccines against multiple diseases.

-

(q)

As plants are a safe biological system and harbor no pathogen of human infections, there are no ethical problems associated with plant edible vaccines unlike the vaccines produced from animal cell cultures and transgenic animals.

-

(r)

Expression of antigen in plant seeds provides a convenient system of vaccine storage for long time duration thus reducing storage and shipping costs under ambient conditions.

-

(s)

Plant cells are able to perform complex posttranslational modification of recombinant proteins, such as glycosylation and disulfide bridging that are often essential for biological activity of many mammalian proteins, allowing for the retention of native biological activity (Lienard et al. 2007; Rybicki 2010; Tremblay et al. 2010)

10.6 Applications of Plant Edible Vaccine

The first report of the concept of using a plant expression system for the production of an edible vaccine appeared in a patent application published under the International Patent Cooperation Treaty (Curtiss and Cardineau 1990). The study aimed to express a surface protein (spaA) from Streptococcus mutans in tobacco plants to a level of approximately 0.02 % of the total leaf protein. The gene for spa production was introduced in tobacco through Agrobacterium-mediated transformation. Mice when feeded on this transgenic tobacco tissue showed oral immunogenicity to spaA protein. However these mice were not further challenged directly with the pathogen but the antibodies recovered from the mice serum demonstrated biological activity against intact S. mutans. However much needed impetus to plant derived vaccine research was given by Arntzen and co workers in 1992 by presenting the concept of plant edible vaccines. In same year an important research paper was published by Mason et al. on the expression of hepatitis B surface antigen (HBsAg) in tobacco plants (Mason et al. 1992). In parallel with evaluation of plant-derived Hepatitis B surface antigen, Mason and Arntzen explored plant expression of other vaccine candidates including the labile toxin B subunit (LT-B) of entertotoxigenic Escherichia coli (ETEC) and the capsid protein of Norwalk virus (NVCP). It was found that the plant derived proteins correctly assembled into functional oligomers that could elicit the expected immune responses when given orally to animals (Haq et al. 1995; Mason et al. 1996, 1998). Subsequently, a number of attempts were made to express various antigens in plants (Table 10.1).

10.6.1 Hepatitis B

Hepatitis B virus (HBV) is one of the major causes of chronic viremia in humans (Purcell 1994). The hepatitis B virus is estimated to have infected 400 million people throughout the globe, making it one of the most common human pathogens. Since immunization is the only known method to prevent the disease of Hepatitis B, any attempt to reduce its infection requires the availability of large quantities of vaccine, hepatitis B surface antigen (HBsAg) (Malik et al. 2011). Mason et al. 1992 demonstrated the expression of HBsAg at levels equal to 0.01 % of total soluble protein in tobacco. However, The low level of expression of the HBsAg in transgenic tobacco (0.01 % of soluble protein) and the alkaloids present in the crude plant extract prevent direct feeding studies. Thus, Mason et al conducted further studies with tobacco-derived recombinant HBsAg (rHBsAg) protein that was recovered from leaf extracts as a VLP with an average size of 22 nm, which are similar to those found in the sera of infected humans and in the commercial vaccine (Cabral et al. 1978). These plant-derived VLPs mimic the appearance of recombinant yeast-derived HBsAg particles (Scolnick et al. 1984), which is the material that is used in commercially available recombinant vaccine for hepatitis B (Recombivaxm; distributed by Merck, Sharpe, and Dohme) and can be injected as vaccinogen directly. In addition, the plant-derived material had similar buoyant density and antigenicity to human and yeast-derived HBsAg, indicating faithful preservation of protein folding characteristics in the plant system’. Thus a crude extract of rHBsAg from plants was used in parenteral immunization studies with mice (Thanavala et al. 1995). The extract caused an immune response that was similar to the one achieved with Recombivaxm, So the studies concluded that the rHBsAg from plants demonstrate that B- and T-cell epitopes of HBsAg are preserved when the antigen is expressed in transgenic plants, and that the recombinant antigen is produced as a VLP that mimics the currently available commercial vaccine. Subsequently many papers were published characterizing the recombinant product which assembled into virus like particles (VLPs), and could invoke specific immune responses in mice upon parenteral delivery.

Further studies were made by Arntzen group to prove that plant-derived HBsAg can stimulate mucosal immune responses via the oral route, for which they employed potato tubers as an expression system and optimized it to increase accumulation of the protein in the plant tubers (Richter et al. 2000). The resulting plant material proved superior to the yeast-derived antigen in both priming and boosting of immune responses to oral immunogen in mice (Kong et al. 2001; Richter et al. 2000). The HBsAg has also been expressed in banana (May et al. 1995) and lettuce (Kapusta et al. 1999). Recently Kumar et al. (2005) transformed embryogenic cells of banana with the ‘s’ gene of hepatitis B surface antigen (HBsAg) using Agrobacterium mediated transformation. The expression levels of the antigen in the plants grown under in vitro conditions as well as the green house hardened plants were estimated by ELISA. Maximum expression level of 38 ng/g F.W. of leaves was noted in plants transformed with pEFEHBS grown under in vitro conditions, whereas pHER transformed plants grown in the green house showed the maximum expression level of 19.92 ng/g F.W. of leaves. HBsAg obtained by them from transgenic banana plants was found to be similar to human serum derived one in buoyant density properties. Kumar et al. (2005) advocated that although expression levels of the antigen are low in banana fruits, the expression levels of the vaccine antigens can be increased by the use of promoter of abundant pulp protein (Clendennen et al. 1998), or promoters of the proteins found in abundance in the ripe banana fruits (Peumans et al. 2002).

10.6.2 Rabies

McGarvey et al. (1995) have reported the expression of rabies virus (RV) glycoprotein in transgenic tomatoes. Although McGarvey et al. did not reported on the immunogenicity of the tomato RV glycoprotein, Yusibov et al. (1997) have reported the induction of neutralizing antibodies in mice that were parenterally vaccinated with a peptide of RV glycoprotein fused to a plant virus coat protein. antigen-capsid fusion is one of the alternative strategies of producing a plant-based vaccine where plants are infected with recombinant viruses carrying the desired antigen in viral coat protein. The infected plants have been reported to produce the desired fusion protein in large amounts in a short time. It should, however, be kept in view that recombinant viruses need to be highly purified for parenteral administration or partially purified for oral administration. Modelska et al. (1998) reported that immunization of mice intraperitoneally or orally by gastric incubation or by feeding of plants infected with the recombinant alfalfa mosaic virus (AIMV) carrying rabies peptide CPDrg showed local as well as systemic immune response. After immunization, 40 % of the mice were protected against the challenge with a lethal dose of the virus. This report also demonstrated stronger immune responses in mice that consumed the chimeric viruses in planta rather than after purification (Modelska et al. 1998). Recently, Loza-Rubio and coworkers developed transgenic maize expressing the rabies virus glycoprotein of the Vnukovo strain and they evaluated its immunogenicity in mice by the oral route. Animals were fed once with 50 μg of protein and challenged 90-days later with a rabies virus isolated from vampire bats. The edible vaccine induced viral neutralizing antibodies which protected mice 100 % against challenge (Loza-Rubio et al. 2008).

10.6.3 Foot and Mouth Disease

The VP1 capsid protein of the foot-and-mouth disease virus (FMDV) was also successfully expressed in transgenic Arabidopsis thaliana (Carrillo et al. 1998). Carrillo and co-workers have shown that mice injected intraperitoneally with the partially purified VP1 protein are totally resistant to a challenge with a virulent strain of the virus. Oral administration of the plant-derived VP1 subunit of FMDV has not been demonstrated. Because FMDV virions are complex structures containing several subunits therefore it is unlikely that the VP1 peptide alone will assemble into stable VLPs.

10.6.4 Cholera

Another important study was regarding Enterotoxigenic Escherichia coli (ETEC) and Vibrio cholera which are the primary pathogens responsible for acute watery diarrhea. Cholera is a devastating diarrheal disease that has caused recurrent pandemics throughout the world since 1871 (Yu and Langridge 2000). The heat-labile enterotoxin (LT) of ETEC is closely related to cholera toxin (CT). Haq et al.(1995) proved that a bacterial antigen (LT-B) could be expressed in edible tissues of transgenic plants and could assemble into pentameric ring structures (as shown by its ability to bind gangliosides). In addition, and most importantly, LT-B expressed in plants was shown to induce the production of both serum and mucosal antibodies in mice fed with transgenic potato tubers. However, the low level of expression of LT-B in potato tubers, implied that people would have to eat an unreasonably large amount of tuber to receive the desired dose. Mason et al. (1998) improved expression levels of LT-B in transgenic plants by the construction of a ‘plant-friendly’ synthetic LT-B gene. The protein product of this synthetic gene accumulates to ~0.15 % of the soluble protein, which is .10-fold higher than the best levels obtained previously by Haq et al. (1995). These higher expression levels have allowed this ‘edible vaccine’ to be tested in humans, representing the first human clinical trial of a plant-derived vaccine where 100 g of raw potato tubers expressing LT-B of ETEC in three doses had to be consumed in order to overcome digestive losses of the antigen and to elicit a significant immune response (Tacket et al. 1998). These results showed, for the first time, that food plant–based vaccines are immunogenic in humans.

Cholera toxin, which is very similar to E. coli LT, has also been expressed in plants. Hein et al. (1996) generated tobacco plants expressing CT-A or CT-B subunits of the toxin. CT-A produced in plant was not cleaved into A1 and A2 subunits, which happens in epithelial cells. While CT-B undergone similar processing in plants as the CT-B derived from V. cholerae, and was thus recognized by mouse anti-CT-B antibody. Antigenically it was found to be similar to the bacterial protein. Even after boiling transgenic potato tubers till they became soft, approximately 50 % of the CT-B was present in the pentameric GM1 ganglioside-binding form (Arakawa et al. 1997, 1998). Higher expression levels (up to 31.1 % TSP) were obtained when CTB-2L21 fusion protein was expressed in transgenic chloroplasts (Molina et al. 2004).

10.6.5 AIDS

According to the WHO, HIV-induced acquired immunodeficiency syndrome (AIDS) kills 1–3 million people annually (UNAIDS 2002). Stable chimeric CPMV particles that express epitopes derived from human rhinovirus 14 and HIV-1 were described by Porta et al. in 1994. The inserted epitopes were immunogenic in rabbits. Initial success was also achieved in splicing HIV protein into CPMV by Prakash (1996). Two HIV protein genes and CaMV as promoter were successfully injected into tomatoes with a needle and the expressed protein was demonstrable by polymerase chain reaction (PCR) in different parts of the plant, including the ripe fruit, as well as in the second generation plant.

10.6.6 Norwalk Virus

Norwalk virus is known to cause acute gastroenteritis in humans. Norwalk virus capsid protein (NVCP) from the diarrhea causing Norwalk virus, expressed in transgenic tobacco and potato with 0.23 % of total soluble protein, also assembled VLPs and stimulated serum IgG and gut IgA specific for NVCP when fed to mice (Mason et al. 1996). The clinical trial was conducted at the Center for Vaccine Development with NVCP potatoes (Tacket et al. 2000). Twenty adults ingested either two or three doses each of 150 g raw potato containing 215–750 lg NVCP. Nineteen of twenty adults showed significant increases in the numbers of specific anti- NVCP antibody-secreting cells of the IgA subtype, and six developed increases in IgG antibody secreting cells. This study proved that orally delivered plant-expressed VLPs could stimulate immune responses and further that GM1 binding activities not required for oral immunization. These results suggest a new strategy for the development of plant vaccines. Individual soluble protein antigens are relatively ineffective for oral immunization because of intestinal digestion and lack of antigen tropism for GALT (gut associated lymphoid tissues). In contrast, VLPs are stable in the acidic environment of the stomach and resistant to enzyme digestion in the small intestine. Most important, VLPs preserve conformational epitopes located on the surface of viral particles, which are recognized by the host immune system. Compared with other viral antigens, the plant-produced VLP may be the more effective antigen for protection against infectious enteric viral diseases (Yu and Langridge 2000). Attempts are underway to engineer bananas and powdered tomatoes expressing norwalk virus.

10.6.7 Malaria

Over two billion individuals reside in the malaria endemic areas and the disease affects 300–500 million people annually. As a result of malarial-infection, an estimated three million lives are lost annually, among them are over one million children (majority under 5 years of age).The world malaria situation has become significantly worse in recent years as the main forms of malaria control, spraying programmes and chemotherapy, becoming less effective in the development of vector and parasite resistance. In a study by Beachy et al. (1996) a 13-amino-acid epitope of zona pellucida, ZP3, protein and another epitope from malarial sporozoites have been expressed as fusion proteins with TMV capsid protein with the idea of developing anti-fertility and anti-malarial vaccines. The antigenicity of the products has been found to be positive. Currently, three malarial antigens are under investigation for the development of plant-based malaria vaccine, merozoite surface protein (MSP) 4,MSP 5 from Plasmodium falciparum, and MSP 4/5 from P. yoelli. Wang et al. (2004) has demonstrated that oral immunization of mice with recombinant MSP 4, MSP 4/5 and MSP1, co-administered with CTB as a mucosal adjuvant, induced antibody responses effective against blood-stage parasite. The study however involved complexity as the protein was expressed in E. coli and protection was only evident when high dose antigen was administered. Thus it is still uncertain if the oral delivery of a plant-derived malaria vaccine would induce significant immune responses in humans. It has been suggested that antigen expression level in plants are so low that an unrealistic quantity of plant material would have to be consumed to achieve meaningful immunity. For this approach to become realistic improve antigenic expression has to be achieved. Moreover, due to high levels of antigen anticipated to be necessary, it is likely that strong adjutants will also be required (Wang et al. 2004). Hence, appropriate adjuvants have to be identified and tested. Finally, in the face of reports showing induction of tolerance or immunity through comparable oral immunizations vaccination regimens must be rigorously tested in preclinical studies (Arakawa et al. 1998).

10.6.8 Autoimmune Diseases

Applications of edible vaccines are expanding to autoimmune diseases where the body’s own proteins recognized as foreign by the immune system. Autoimmune diseases include arthritis, myasthenia gravis, multiple sclerosis and type I diabetes. It was established by Arakawa et al. (1998) that food plants are feasible production and delivery systems for immunotolerization against autoimmune diseases. They found cholera toxin B to be useful as a carrier molecule for specific targeting to the gut-associated lymphoid tissue (GALT). A cholera toxin B–insulin fusion protein produced in transgenic potato plants successfully protected non obese diabetic mice from development of autoimmune diabetes mellitus type I.

Ma and Jevnikar (1999) expressed glutamic acid dehydrogenase in potatoes and fed them to non-obese diabetic mice, in which the reduced pancreatic islet inflammation suggested immuno- tolerization of cytotoxic T-cell-mediated autoimmune disease. An optimal oral dose of a plant-derived auto antigen can potentially inhibit development of the autoimmune disease (Carter and Langridge 2002; Sala et al. 2003). Edible vaccine development for the prevention or treatment of cancer is difficult since tumor antigens are also auto-antigens (Zhang et al. 1998). Recently, a poly-epitope isolated from a human melanoma tumor was integrated into the nuclear and chloroplast DNA of tobacco in an attempt to develop a plant-derived melanoma vaccine (Sala et al. 2003). McCormick et al. (1999) expressed a scFv antibody fragment of the immunoglobulin from a mouse B-cell lymphoma in tobacco with a viral vector and showed that mice injected with this vaccine were protected from challenge by a lethal dose of tumor. Another scFv fused to the potato virus X coat protein generated protection against lymphoma and myeloma (Savelyeva et al. 2001).

10.7 Potential Issues to Be Addressed

There were many questions regarding plant edible vaccines when the concept was given by Arntzen and group in 1990s. Some of them were answered in the course of successive development in this field while some still remain unanswered. Even after all the research and developments made in plant derived edible vaccines, there are some limitations and issues which are still to be addressed. A major impediment in the successful application of these vaccines is the low expression level of antigen and uncertain dosage. In all the studies mentioned above the expression level of antigen in plant tissue was not of practical utilization as to achieve the required immunity very large amount of plant product is need to be consumed. In addition, not all vaccine candidate proteins are highly immunogenic in plant tissues and secondary metabolites found in plants may compromise the ability of the vaccine candidate protein to induce immunity (Teli and Timko 2004). Two solutions to overcome this limitation are being explored. First, techniques to enhance antigen accumulation in plant tissues are being explored. A number of factors, including genes encoding vaccine antigens can be optimized for plant codon use; plant promoters can be engineered to increase transcription levels; RNA splice sites and intron sequences can be removed codon usage, the type of 5′-untranslated sequence incorporated, the presence of specific intra- and extracellular targeting or compartmentalization sequences present, the site of gene integration into the genome, etc. affect transgene expression and ultimately vaccine epitope accumulation in plants. Optimization of coding sequences of bacterial or viral genes for transient expression, as well as defining the best subcellular compartment for product accumulation to obtain optimal quantity and quality, is also being studied (Teli and Timko 2004). To enhance the immunogenicity of the orally delivered antigens, the use of carrier proteins may also be required, especially for small, non-particulate subunit vaccine antigens (Walmsley and Arntzen 2000). Another approach is to use bacterial enterotoxins such as CT or LT (Mason and Arntzen 1995), mammalian and viral immunomodulator, or plant-derived secondary metabolites (Yu and Langridge 2001). Although the constitutive expression of foreign genes may lead to the accumulation of foreign proteins to levels toxic in the plant, inducible promoters, which stimulate gene expression at specific points in plant development, may not only prevent accumulation of toxic levels of the foreign gene product but may conserve the plant’s photosynthate for generation of maximum plant growth, resulting in higher yields of recombinant proteins (Arakawa et al. 1997, 1998). Thus, temporal and organ- and tissue-specific promoters activated in fruit, tubers, or seeds must be explored (Fiedler and Conrad 1995).

Another problem is that the glycosylation of trans proteins in plants differs slightly from those produced in transgenic animals or animal cells in vitro (Lerouge et al. 1998). The addition of xylose and change from a b1!6 to a b1!3 linkage of fucose are typical in plants. A significant difference with transprotein production in plants is their inability to add sialic acid to glycoproteins (Lerouge et al. 1998). This sugar has been implicated in longer clearance times for proteins in the blood and therefore is a major factor for a select group of pharmaceutical proteins. However, plant glycan patterns may not represent a problem in terms of human health; they may affect conformational epitopes, or clearance of plant derived antibodies (Bakker et al. 2001; Ma et al. 2005). This potential problem is likely to be overcome as we learn more about the requirements for these processes in both plant and animal cells (Bakker et al. 2001).

Another concern is about the potential contamination of plant-derived recombinant proteins with potentially toxic factors due to the fact that some plant species contain numerous toxic alkaloids and other secondary metabolites. Careful selection of appropriate plant materials for heterologous expression can help alleviate this potential problem (Teli and Timko 2004).

Another major concern is the possibility of development of immunotolerance to the vaccine protein or peptide. Also there will be a challenge in controlling transgene escape as the identification of “vaccine” fruit vs a normal fruit would be difficult. Fruit vaccines should be easily identifiable to avoid the misadministration of the vaccine, which may lead to complications such as immunotolerance. Also the oral vaccines are complicated by the need to protect the antigen from the effects of the acidic and proteolytic environment of the gut. Hence, to be effective, oral subunit vaccines generally require higher doses than oral replicating vaccines (Walker 1994; Mestecky et al. 1997) Allergic reactions to plant protein glycans and other plant antigens is a challenging issue. It has been suggested that plant derived recombinant proteins or antibodies may have increased immunogenicity or allergenicity as compared to mammalian counterparts (Ma et al. 2005; Penney et al. 2011). This is well explained by the fact that a state of tolerance or energy has been gained by the daily consumption of plant glycolproteins in our food (Ma et al. 2005).

Some other potential problems related to plant edible vaccines include:

-

(a)

Plant and product contamination by mycotoxins, pesticides, herbicides and endogenous metabolites.

-

(b)

Regulatory uncertainty, particularly for proteins requiring approval for human drug use (Doran 2000).

-

(c)

Consistency of dosage from fruit, plant to plant, generation to generation is not similar

-

(d)

Stability of vaccine in fruit is not known and differs from plant to plant.

-

(e)

Some food cannot be eaten raw (e.g. potato) and needs cooking which will denature or weaken the protein present in it (Moss et al. 1999)

-

(f)

Variable conditions for edible vaccine are also a major problem. Potatoes containing vaccine to be stored at 4 °C and could be stored for longer time while a tomato does not last long. Thus these vaccines need to be properly stored to avoid infection through microbial spoilage.

Thus while the plant edible vaccines are a lucrative option in the field of vaccination, there is much remains to be done in this field. With many potential issues to be addressed this area of health care is open for exhaustive research and development.

10.8 Transgenic Chloroplast Systems

Transgenic chloroplasts have become attractive systems for heterologous gene expressions because of unique advantages. Chloroplast genetic engineering offers several advantages, including high levels of transgene expression, transgene containment via maternal inheritance, and multi-gene expression in a single transformation event (Chebolu and Daniell 2009). The highest level of protein expression through transgenic tobacco chloroplast was obtained for Bacillus thuringiensis (Bt) cry2Aa2 protein (46.1 % TSP) (De Cosa et al. 2001). As chloroplasts are genetically semi autonomous having their independent genome, many self replicating copies of transformed plastids can be produced in a single plant cell thus enhancing the antigen/ protein yield considerably.

There are several other advantages of chloroplast transformation system over nuclear transformation. Environmental concerns about mixing genetically modified pollen with other crops or weeds have been continually raised (Stokstad and Vogel 2003). This objection may be partially addressed by engineering the foreign gene into the chloroplast DNA (Ruf et al. 2001). As chloroplast genome is maternally inherited it does not follow Mendelian pattern of inheritance (Zhang et al. 2003) so gene pollution caused by transgene escape through pollen can be controlled. Even if the pollen from plants that exhibit maternal inheritance contains metabolically active plastids, the plastid DNA is lost during pollen maturation and is not transmitted to the next generation (Daniell et al. 2002). Therefore, the chloroplast expression system is an environmentally friendly approach. Chaperones present in chloroplasts facilitate correct folding and assembly of monoclonal antibody in transgenic chloroplasts (Daniell et al. 2004) and also result in fully functional human therapeutic proteins, as seen in interferon alpha and gamma (Falconer 2002; Leelavathi and Reddy 2003). Chloroplasts have the ability to process eukaryotic proteins, including correct folding of subunits and formation of disulfide bridges (Daniell et al. 2001b). Chloroplast-synthesized cholera toxin-B subunit binds to the intestinal membrane GM1-ganglioside receptor, thereby confirming the correct folding and disulfide bond formation through functional assay (Daniell et al. 2001a; Molina et al. 2004).

Also, chloroplasts have the ability to express multiple genes in a single transformation event. Expression of polycistrons in transgenic chloroplasts is a unique feature, which facilitates the expression of entire pathways in a single transformation event (De Cosa et al. 2001; Daniell and Dhingra 2002). De Cosa et al. (2001) for the first time expressed a complete bacterial operon in transgenic chloroplasts, resulting in the formation of stable cry2Aa2 crystals. This should facilitate expression of polyvalent vaccines or multisubunit proteins in transgenic chloroplasts (Chebolu and Daniell 2009). Problem of gene silencing is also eliminated in chloroplast expression systems. Inspite of higher expression level gene silencing was not observed in transgenic chloroplast derived plants (De Cosa et al. 2001). Chloroplasts can be a good place to store the biosynthetic products that could otherwise be harmful when accumulated in cytosol (Bogorad 2000). This was demonstrated when cholera toxin B subunit was accumulated in large quantities in transgenic chloroplasts and it had no toxic effect (Daniell et al. 2001a), whereas when accumulated in the cytosol in very small quantities, CTB was toxic (Mason et al. 1998). Similarly, trehalose, was toxic when accumulated in cytosol but was nontoxic when compartmentalized within chloroplasts (Lee et al. 2003).

However chloroplast transformation is also not untouched with certain limitations and issues. As with any fresh tissue molecular farming system, protein stability over time will change even with refrigeration. Extraction and purification must be performed at very specific times following harvest. Tobacco is currently a highly regulated crop and is not edible. Large volume products and edible vaccines would not appear to be feasible using this system (Horn et al. 2004). Tobacco appears to be the only species in which plastid transformation has been established as routine (Svab and Maliga 1993; Daniell et al. 2002). However, recently Kanamoto et al. (2006) developed plastid transformation system for lettuce.

10.9 Recent Developments

Currently the researches in plant edible vaccine production are emphasizing on good manufacturing practices (GMP) with increased antigen expression being the everlasting objective of this technology. Recently a novel technique developed by Icon Genetics (Bayer Crop science, Germany), based on the Magnifection, has additional advantageous than the routine methods used for the production of subunit vaccines in plants. This system allows very fast production, high recombinant protein expression levels for example hepatitis B virus (HB core) with an accumulation level exceeding 7 % of total soluble protein in tobacco (Gomez et al. 2010; Yusibov and Rabindran 2008; Gleba et al. 2005; Huang et al. 2006).

Recently Alvarez et al. (2010) conducted an important study on enhancing recombinant protein expression in transgenic plants. They suggested that in maize, γ-Zein is the major storage protein synthesized by the rough endoplasmic reticulum (ER) and stored in specialized organelles called protein bodies (PB). Zera® (γ-Zein ER-accumulating domain) is the N-terminal proline-rich domain of c-zein that is sufficient to induce the assembly of PB formation. Fusion of the Zera® domain to proteins of interest results in assembly of dense PB-like, ER-derived organelles, containing high concentration of recombinant protein. To confirm this, they expressed F1-V antigen protein from Yersinia pestis (causal pathogen of plague) in three plant models (Ncotiana benthamiana, Medicago sativa (alfalfa) and Nicotiana tabacum NT1 cells) with and without a fused Zera® domain. They found that F1-V protein with fused Zera® domain showed three times more accumulation in plant cells than F1-V protein alone.

The list of diseases that could potentially be prevented with plant-based, edible vaccines is keeping on increasing. Clinical trials have already succeeded in increasing the production of antibodies against HIV in mice (Karasev et al. 2005) On the other hand, soybean has been genetically modified to produce monoclonal antibodies that act as carriers of cancer-attacking compounds. The possibility of developing HIV and cancer vaccines through transgenic plants could be a major step in the fight against these devastating diseases. Highly pathogenic H5N1 avian influenza responsible for global pandemics and with mortality rates exceeding 60 % encouraged global efforts to develop vaccines against this highly pathogenic avian influenza (HPAI). Shoji et al. (2009) recently described the production of HA from the A/Indonesia/05/05 strain of H5N1 influenza virus by transient expression in Nicotiana benthamiana plants. They demonstrated that immunization of mice and ferrets with this plant-derived HA protected ferrets against challenge infection with a homologous virus.

Sexually transmitted diseases are also now included in the domain of plant based vaccination. Maclean et al. (2007) have reported the expression of L1 capsid protein from HPV-16. By a transient expression assay, the authors determined not only that L1 protein was capable of assemble into VLPs, maintaining its immunological properties, but that a human instead of a plant codon usage and the protein-direction to the chloroplast, were the best conditions to achieve high yields of recombinant L1 protein (11 % of TSP in transgenic tobacco). These results showed an efficacious way of producing VLPs onward HPV vaccine, maybe a cheaper one than the new HPV vaccine produced in insect cells. Immunizing experiments are needed to better prove this hypothesis. Obregon and coworkers showed a new strategy for increasing recombinant protein production in HIV by improved the stability of p24 core protein. This stable protein formed dimmers that were retained within the cell resulting in an enhanced expression, apparently related to protein folding processing and assembly, subcellular targeting and protein stability (Obregon et al. 2006). Recently, Saejung et al. (2007) reported, for the first time, the production of a dengue vaccine in plants. Takagi et al. (2005) reported GM rice expressing two T-cell epitope peptides of Cry j I and Cry j II allergens of Japanese cedar (Cryptomeria japonica) pollen.

Multicomponent edible plant vaccines providing immunologic protection simultaneously against several infectious diseases are under construction. Recently in this context (Shchelkunov et al. 2006) demonstrated a bivalent vaccine synthesis through a synthetic chimeric gene, TBI-HBS, encoding the immunogenic ENV and GAG epitopes of human immunodeficiency virus (HIV-1) and the surface protein antigen (HBsAg) of hepatitis B virus (HBV), was expressed in tomato plants. Tomato fruits containing the TBI-HBS antigen were fed to experimental mice and, on days 14 and 28 post-feeding, high levels of HIV and HBV-specific antibodies were present in the serum and feces of the test animals. Intraperitoneal injection of a DNA vaccine directing synthesis of the same TBI-HBsAg antigen boosted the antibody response to HIV in the blood serum; however, it had no effect on the high level of antibodies produced to HBV. Although no plant-based edible vaccines are currently commercially available, a secretory antibody vaccine was approved in the EU, a poultry vaccine against Newcastle disease was approved by the USDA, and a hepatitis B virus vaccine using a tobacco plant has been approved in Cuba (Kim and Yang 2010). Vaccines for diarrhea, hepatitis B and rabies, and antibodies for non-Hodgkin’s lymphoma, colorectal cancer and dental caries, have been submitted for phase I or phase II clinical trials in humans (Ma et al. 2005). Korban and colleagues at the University of Illinois (Urbana-Champaign, Ill.) have reported a plant-based oral vaccine against respiratory syncytial virus (RSV) in tomato fruit (Korban et al. 2002) with the ultimate aim of moving the product into apple. HSV is a viral pathogen that causes respiratory diseases and is a leading cause of viral lower respiratory tract illness in infants and children worldwide. Aziz et al. (2002) paved way for developing edible vaccines against anthrax by successfully expressing the protective antigen against anthrax in potato tubers.

10.10 Conclusions

Plant edible vaccines have the potential to change the whole scenario of vaccination. Upto few years ago vaccination was only limited to six deadly diseases in children but now not only human but animal diseases of bacterial, viral even protozoan origin are being successfully studied for vaccination. Not only this but the researches are ongoing to provide plant based vaccines for autoimmune diseases like diabetes and cancer which has risen the need of these vaccines for developed countries also which till now were emphasized to be important majorly for developing countries. Apart from many advantages of these vaccines there are some very relevant social, environmental and ethical issues concerning them which are need to be addressed. Besides future research is needed to overcome limitations like low expression, immunotolerance, glycosylation, immunogenicity, and stability of the transproteins if the practical application of these vaccines is to be realized. One very important point is the proper coordination between academia and industry to help these vaccines reach people. Both technical and regulatory hurdles have to be overcome. It will be a challenge to create a positive public perception regarding safety and efficacy of these vaccines after all the fuss created over the safety issues of transgenic crops during last few years. Lastly timely funding for this research and participation of corporate giant will certainly help in making this dream a reality soon.

References

Adams, S. E., Dawson, K. M., Gull, K., Kingsman, S. M., & Kingsman, A. J. (1987). The expression of hybrid HIV-Ty virus-like particles in yeast. Nature, 329, 68–70.

Alvarez, M. L., Topal, E., Martin, F., & Cardineau, G. A. (2010). Higher accumulation of F1-V fusion recombinant protein in plants after induction of protein body formation. Plant Molecular Biology, 72, 75–89.

Arakawa, T., Chong, D. K., Merritt, J. L., & Langridge, W. H. (1997). Expression of cholera toxin B subunit ologomers in transgenic potato plants. Transgenic Research, 6, 403–413.

Arakawa, T., Yu, J., Chong, D. K., Hough, J., Engen, P. C., et al. (1998). A plant-based cholera toxin B subunit-insulin fusion protein protects against the development of autoimmune diabetes. Nature Biotechnology, 16, 934–938.

Arntzen, C. J. (1997). Edible vaccines. Public Health Reports, 112, 190–197.

Aziz, M. A., Singh, S., Kumar, P. A., & Bhatnagar, R. (2002). Expression of protective antigen in transgenic plants: A step towards edible vaccine against anthrax. Biochemical and Biophysical Research Communications, 299, 345–351.

Bakker, H., Bardor, M., Molthoff, J. W., Gomord, V., Elbers, I., & Stevens, L. H. (2001). Galactose extended glycans of antibodies produced by transgenic plants. Proceedings of the National Academy of Sciences of the United States of America, 98, 2899–2904.

Barta, A., et al. (1986). The expression of a nopaline synthase human growth hormones chimeric gene in transformed tobacco and sunflower callus tissue. Plant Molecular Biology, 6, 347–357.

Beachy, R. N., Fitchen, J. H., & Hein, M. B. (1996). Use of plant viruses for delivery of vaccine epitopes. Annals of the New York Academy of Sciences, 792, 43–49.

Bogorad, L. (2000). Engineering chloroplasts: An alternative site for foreign genes, proteins, reactions and products. Trends in Biotechnology, 18, 257–263.

Bouche, F. B., Marquet-Blouin, E., Yanagi, Y., Steinmetz, A., & Muller, C. P. (2003). Neutralising immunogenicity of a polyepitope antigen expressed in a transgenic food plant: A novel antigen to protect against measles. Vaccine, 21, 2065–2072.

Cabral, G. A., Marciano-Cabral, F., Funk, G. A., Sanchez, Y., Hollinger, F. B., Melnick, J. L., & Dreesman, G. R. (1978). Cellular and humoral immunity in guinea pigs to two major polypeptides derived from hepatitis B surface antigen. Journal of General Virology, 38, 339–350.

Carrillo, A., Stewart, K. D., Sham, H. L., Norbeck, D. W., Kohlbrenner, W. E., Leonard, J. M., Kempf, D. J., & Molla, A. (1998). In vitro selection and characterization of human immunodeficiency virus type 1 variants with increased resistance to ABT-378, a novel protease inhibitor. Journal of Virology, 72, 7532–7541.

Carter, J. E., & Langridge, W. H. R. (2002). Plant-based vaccines for protection against infectious and autoimmune diseases. Critical Reviews in Plant Sciences, 21, 93–109.

Chebolu, S., & Daniell, H. (2009). Chloroplast-derived vaccine antigens and biopharmaceuticals: Expression, folding, assembly and functionality. Current Topics in Microbiology and Immunology, 332, 33–54.

Clarke, B. E., Brown, A. L., Grace, K. G., Hastings, G. Z., Brown, F., Rowlands, D. J., & Francis, M. J. (1990). Presentation and immunogenicity of viral epitopes on the surface of hybrid hepatitis B virus core particles produced in bacteria. Journal of General Virology, 71, 1109–1117.

Clendennen, S. K., Lopez-Gomez, R., Gomez-Lim, M., Arntzen, C. J., & May, G. D. (1998). The abundant 31-kilodalton banana pulp protein is homologous to class III acidic chitinases. Phytochemistry, 47, 613–619.

Curtiss, R., & Cardineau, G. A. (1990). World Intellectual Property Organization, PCT/US89/03799.

Daniell, H., & Dhingra, A. (2002). Multigene engineering: Dawn of an exciting new era in biotechnology. Current Opinion in Biotechnology, 13, 136–141.

Daniell, H., Lee, S. B., Panchal, T., & Wiebe, P. (2001a). Expression of native cholera toxin B sub-unit gene and assembly as functional oligomers in transgenic tobacco chloroplasts. Journal of Molecular Biology, 311, 1001–1009.

Daniell, H., Streatfield, S. J., & Wycoff, K. (2001b). Medical molecular farming: Production of antibodies, biopharmaceuticals and edible vaccines in plants. Trends in Plant Science, 6, 219–226.

Daniell, H., Khan, M. S., & Allison, L. (2002). Milestones in chloroplast genetic engineering: An environmentally friendly era in biotechnology. Trends in Plant Science, 7, 84–91.

Daniell, H., Carmona-Sanchez, O., & Burns, B. (2004). Chloroplast derived antibodies, biopharmaceuticals and edible vaccines. In R. Fischer & S. Schillberg (Eds.), Molecular farming (pp. 113–133). Weinheim: Wiley-VerlagVCH.

Daniell, H., Singh, N. D., Mason, H., & Streatfield, S. J. (2009). Plant–made vaccine antigens and biopharmaceuticals. Trends in Plant Science, 14, 669–679.

Davoodi-Semiromi, A., Samson, N., & Daniell, H. (2009). The green vaccine: A global strategy to combat infectious and autoimmune diseases. Human Vaccines, 5, 488–493.

Davoodi-Semiromi, A., Schreiber, M., Nallapali, S., Verma, D., Singh, N. D., Banks, R. K., Chakrabarti, D., & Daniell, H. (2010). Chloroplast-derived vaccine antigens confer dual immunity against cholera and malaria by oral or injectable delivery. Plant Biotechnology Journal, 8, 223–242.

De Cosa, B., Moar, W., Lee, S. B., Miller, M., & Daniell, H. (2001). Over expression of the cry2Aa2 operon in chloroplasts leads to formation of insecticidal crystals. Nature Biotechnology, 19, 71–74.

Dedieu, J. F., Ronco, J., Van der Werf, S., Hogle, J. M., Henin, Y., & Girard, M. (1992). Poliovirus chimeras expressing sequences from the principle neuralising domain of human immunodeficiency virus type 1. Journal of Virology, 66, 3161–3167.

Desai, P. N., Shrivastava, N., & Padh, H. (2010). Production of heterologous proteins in plants: Strategies for optimal expression. Biotechnology Advances, 28, 427–435.

Doran, P. M. (2000). Foreign protein production in plant tissue cultures. Current Opinion in Biotechnology, 11, 199–204.

Estes, M. K., Ball, J. M., Crawford, S. E., O’Neal, C., Opekun, A. A., Graham, D. Y., & Conner, M. E. (1997). Virus-like particle vaccines for mucosal immunization. Advances in Experimental Medicine and Biology, 412, 387–395.

Falconer, R. (2002). Expression of Interferon alpha 2b in transgenic chloroplasts of a low-nicotine tobacco. M.S. thesis, University of Central Florida, Orlando.

Fiedler, U., & Conrad, U. (1995). High-level production and long-term storage of engineered antibodies in transgenic tobacco seeds. Biotechnology, 13, 1090–1093.

Garside, P., & Mowat, A. M. (1997). Mechanisms of oral tolerance. Critical Reviews in Immunology, 17, 119–137.

Giddings, G., Allison, G., Brooks, D., & Carter, A. (2000). Transgenic plants as factories for biopharmaceuticals. Nature Biotechnology, 18, 1151–1155.

Gleba, Y., Klimyuk, V., & Marillonnet, S. (2005). Magnifection-a new platform for expressing recombinant vaccines in plants. Vaccine, 23, 2042–2048.

Gómez, N., Wigdorovitz, A., Castañón, S., Gil, F., Ordás, R., Borca, M. V., et al. (2000). Oral immunogenicity of the plant derived spike protein from swine-transmissible gastroenteritis coronavirus. Archives of Virology, 145, 1725–1732.

Gomez, E., Zoth, S. C., Carrillo, E., & Berinstein, A. (2010). Developments in plant-based vaccines against diseases of concern in developing countries. The Open Infectious Diseases Journal, 4, 55–62.

Haq, T. A., Mason, H. S., Clements, J. D., & Arntz, C. J. (1995). Oral immunization with a recombinant bacterial antigen produced in transgenic plants. Science, 268, 714–716.

Hein, M. B., Yeo, T. C., Wang, F., & Sturtevant, A. (1996). Expression of cholera toxin subunits in plants. Annals of the New York Academy of Sciences, 792, 51–56.

Hiatt, A., Cafferkey, R., & Bowdish, K. (1992). Production of antibodies in transgenic plants. Proceedings of the National Academy of Sciences of the United States of America, 89, 11745–11749.

Horn, M. E., Woodard, S. L., & Howard, J. A. (2004). Plant molecular farming: Systems and products. Plant Cell Reports, 22, 711–720.

Huang, Z., Santi, L., LePore, K., Kilbourne, J., Arntzen, C. J., & Mason, H. S. (2006). Rapid, high level production of hepatitis B core antigen in plant leaf and its immunogenicity in mice. Vaccine, 24, 2506–2513.

Jiang, X. L., He, Z. M., Peng, Z. Q., Qi, Y., Chen, Q., & Yu, S. Y. (2007). Cholera toxin B protein in transgenic tomato fruit induces systemic immune response in mice. Transgenic Research, 16, 169–175.

Kanamoto, H., Yamashita, A., Asao, H., Okumura, S., Takase, H., Hattori, M., Yokota, A., & Tomizawa, K. I. (2006). Efficient and stable transformation of Lactuca sativa L. cv. Cisco (lettuce) plastids. Transgenic Research, 15, 205–217.

Kang, T. J., Kang, K. H., Kim, J. A., Kwon, T. H., Jang, Y. S., & Yang, M. S. (2004). High-level expression of the neutralizing epitope of porcine epidemic diarrhea virus by a tobacco mosaic virus based vector. Protein Expression and Purification, 38, 129–135.

Kapusta, J., Modelska, A., Figlerowicz, M., Pniewski, T., Letellier, M., Lisowa, O., Yushibov, V., Koprowski, H., Plucienniczak, A., & Legocki, A. N. (1999). A plant-derived vaccine against hepatitis B virus. The FASEB Journal, 13, 1796–1799.

Karasev, A. V., Foulke, S., Wellens, C., Rich, A., Shon, K. J., Zwierzynski, I., et al. (2005). Plant based HIV-1 vaccine candidate: Tat protein produced in spinach. Vaccine, 23, 1875–1880.

Kim, T., Galloway, D., & Langridge, W. (2004). Synthesis and assembly of anthrax lethal factor cholera toxin B-subunit fusion protein in transgenic potato. Molecular Biotechnology, 28, 175–183.

Kim, T. G., & Yang, M. S. (2010). Current trends in edible vaccine development using transgenic plants. Biotechnology and Bioprocess Engineering, 15, 61–65.

Kong, Q., Richter, L., Yang, Y. F., Arntzen, C. J., Mason, H. S., & Thanavala, Y. (2001). Oral immunization with hepatitis B surface antigen expressed in transgenic plants. Proceedings of the National Academy of Sciences of the United States of America, 98, 11539–11544.

Koprowski, H., & Yushibov, V. (2001). The green revolution: Plants as heterologous expression vectors. Vaccine, 19, 2735–2741.

Korban, S. S., Krasnyanski, S. F., & Buetow, D. E. (2002). Foods as production and delivery vehicles for human vaccines. Journal of the American College of Nutrition, 21, 2125–2175.

Kumar, G. B. S., Ganapathi, T. R., Revathi, C. J., Srinivas, L., & Bapat, V. A. (2005). Expression of hepatitis B surface antigen in transgenic banana plants. Planta, 222, 484–493.

Lal, P., Ramachandran, V. G., Goyal, R., & Sharma, R. (2007). Edible vaccines: Current status and future. Indian Journal of Medical Microbiology, 25, 93–102.

Langridge, W. H. R. (2006). Edible vaccines. Scientific American Report, 1, 46–53.

Lee, S. B., Kwon, H. B., Kwon, S. J., Park, S. C., Jeong, M. J., Han, S. E., Byun, M. O., & Daniell, H. (2003). Accumulation of trehalose within transgenic chloroplasts confers drought tolerance. Molecular Breeding, 11, 1–13.

Leelavathi, S., & Reddy, V. S. (2003). Chloroplast expression of His-tagged GUS-fusions: A general strategy to overproduce and purify foreign proteins using transplastomic plants as bioreactors. Molecular Breeding, 11, 49–58.

Lerouge, P., Cabanes-Macheteau, M., Rayon, C., Fischette-Laine, A.-C., Gomord, V., & Faye, L. (1998). N-glycoprotein biosynthesis in plants: Recent developments and future trends. Plant Molecular Biology, 38, 31–48.

Lienard, D., Sourrouille, C., Gomord, V., & Faye, L. (2007). Pharming and transgenic plants. Biotechnology Annual Review, 13, 115–147.

Lomonossoff, G., & Johnson, J. E. (1995). Eukaryotic viral expression systems for polypeptides. Seminars in Virology, 6, 257–267.

Loza-Rubio, E., Rojas, E., Gómez, L., et al. (2008). Development of an edible rabies vaccine in maize using the Vnukovo strain. Developments in Biologicals (Basel), 131, 477–482.

Ma, S., & Jevnikar, A. M. (1999). Auto antigens produced in plants for oral tolerance therapy of autoimmune diseases. Advances in Experimental Medicine and Biology, 464, 179–194.

Ma, S., Huang, Y., Yin, Z., Menassa, R., Brandle, J. E., & Jevnikar, A. M. (2004). Induction of oral tolerance to prevent diabetes with transgenic plants requires glutamic acid decarboxylase (GAD) and IL-4. Proceedings of the National Academy of Sciences of the United States of America, 101, 5680–5685.

Ma, J. K. C., Drake, P. M. W., Chargelegue, D., Obregon, P., & Prada, A. (2005). Antibody processing and engineering in plants, and new strategies for vaccine production. Vaccine, 23, 1814–1818.

Maclean, J., Koekemoer, M., Olivier, A. J., et al. (2007). Optimization of human papillomavirus type 16 (HPV-16) L1 expression in plants: Comparison of the suitability of different HPV-16 L1 gene variants and different cell-compartment localization. Journal of General Virology, 88, 1460–1469.

Malabadi, R. B. (2008). Production of edible vaccines for oral immunization in transgenic plants, current and future prospective. Journal of Phytological Research, 21, 1–10.

Malabadi, R. B., Meti, N. T., Mulgund, G. S., Nataraja, K., & Vijaya Kumar, S. (2012). Recent advances in plant derived vaccine antigens against human infectious diseases. Research in Pharmacy, 2, 8–19.

Malik, A., Vashishta, V. K., Rizwan, R., Sharma, S., & Singh, J. (2011). Edible vaccine-vegetables as alternative to needles. International Journal of Current Research, 3, 18–26.

Mason, H. S., & Arntzen, C. J. (1995). Transgenic plants as vaccine production systems. Trends in Biotechnology, 13, 388–392.

Mason, H. S., Lam, D. M. K., & Arntzen, C. J. (1992). Expression of hepatitis B surface antigen in transgenic plants. Proceedings of the National Academy of Sciences of the United States of America, 89, 11745–11749.

Mason, H. S., Ball, J. M., Shi, J. J., Jiang, X., Estes, M. K., & Arntzen, C. J. (1996). Expression of Norwalk virus capsid protein in transgenic tobacco and protein and its oral immunogenicity in mice. Proceedings of the National Academy of Sciences of the United States of America, 93, 5335–5340.

Mason, H. S., Haq, T. A., Clements, J. D., & Arntzen, C. J. (1998). Edible vaccine protects mice against E. coli heat-labile enterotoxin (LT): Potatoes expressing a synthetic LT-B gene. Vaccine, 16, 1336–1343.

Mastico, R. A., Talvot, S. J., & Stockley, P. G. (1993). Multiple presentation of foreign peptides on the surface of an RNA-free bacteriophage capsid. Journal of General Virology, 74, 541–548.

May, G. D., Afza, R., Mason, H. S., Wiecko, A., Novak, F. J., & Arntzen, C. J. (1995). Generation of transgenic banana (Musa acuminata) plants via Agrobacterium-mediated transformation. Biotechnology, 13, 486–492.