Abstract

A TRU-burning fast reactor cycle associated with a uranium-free trans-uranium (TRU) metallic fuel core is one of the solutions for radioactive waste management issue. Use of TRU metallic fuel without uranium makes it possible to maximize the TRU transmutation rate in comparison with uranium and plutonium mixed-oxide fuel because it prevents the fuel itself from producing new plutonium and minor actinides, and furthermore because metallic fuel has much smaller capture-to-fission ratios of TRU than those of mixed-oxide fuel. Also, adoption of metallic fuel enables recycling system to be less challenging, even for uranium-free fuel, because a conventional scheme of fuel recycling by electrorefining and injection casting is applicable.

There are some issues, however, associated with a uranium-free TRU metallic fuel core: decrease in negative Doppler reactivity coefficient from the absence of uranium-238, which has the ability to absorb neutrons at elevated temperatures, increase in burn-up swing, because fissile decreases monotonically in uranium-free core, and so on. The purpose of this paper is to evaluate the feasibility of the uranium-free TRU metallic fuel core by investigating the effect of measures taken to enhance Doppler reactivity feedback and to reduce burn-up swing. The results show a TRU-burning fast reactor cycle using uranium-free TRU metallic fuel is viable from the aforementioned points of view because the introduction of diluent Zr alloy, spectrum moderator BeO, and lower core height enables Doppler reactivity coefficient and burn-up reactivity swing of uranium-free TRU metallic fuel to be as practicable as those of conventional fuel containing uranium.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

For sustainable nuclear power deployment, not only ensuring its enhanced safety but also reduction of the environmental burden associated with radioactive waste management is a challenging issue for the international community. History has shown that obtaining public support is difficult for waste management plans that involve mass disposal of radioactive waste with a half-life of tens of thousands of years. Therefore, as one of the solutions, Toshiba has been developing a system that takes into account that, for the time being, light water reactors (LWRs) have a leading role in commercial nuclear power plants, which enables toxicity and radioactivity of high-level waste to be reduced to those of natural uranium within a few hundred years. This system is mainly characterized by a fast reactor core that does not contain uranium in its fuel, that is, uranium-free TRU fuel. The use of uranium-free TRU fuel makes it possible to maximize the TRU transmutation rate in comparison with fuel containing uranium because it prevents the fuel itself from producing new plutonium and minor actinides.

Although there was much research focused on TRU transmutation with uranium-free fuels, each of these seems to have drawbacks from some aspect. First, for instance, candidates such as Tc-based and W-based oxide fuel, inert matrix fuel such as the rock-like oxide fuel containing mineral-like compounds, and MgO-based oxide fuel provide solutions against issues associated with uranium-free operation, that is, decrease in Doppler reactivity feedback and increase in sodium void reactivity [1–3], but such types of inert matrix fuel may require new technologies for reprocessing. Additionally, many processing phases necessary for fabrication are costly. Second, an accelerator-driven transmutation system coupled with a fast reactor using uranium-free metallic fuel is another candidate that also can relax the issue of the reduced Doppler effect owing to its subcritical system [4–7], but installation of the accelerator facility at a fast reactor site is less cost competitive, especially when the system is not only a TRU burner but also a commercial power plant. Thus, it is worthwhile to develop the TRU transmutation system with uranium-free TRU fuel from the aspect of technological maturity and simplicity, which results in lower cost. Subsequently, the concepts for the TRU burner system with uranium-free TRU are derived from this background: fewer R&D needs and a simple system.

First, by contrast with inert matrix fuels, metallic fuel can be fabricated by the well-known injection casting method [8]. Moreover, metallic fuel is compatible with pyro-process reprocessing that has been developed since the 1960s [9]. Application of an accelerator-driven system for transmutation needs further R&D than that of a fast reactor system. Thus, the metallic fuel fast reactor is preferred for the system.

Second, we aim to develop the TRU-burning system in commercial power reactors while avoiding cost impact. For this reason, a system that can employ the pyro-process for fuel reprocessing would be preferable because it does not need complex processes. Therefore, we introduce a metal fuel alloy that can be simply fabricated by injection casting and reprocessed by pyro-processing.

Additionally, in terms of reduction of nuclear waste burden, a metallic fuel fast reactor cycle has the great potential to transmute long-lived fission products (LLFPs) because of its excellent neutron economy [10, 11]. Moreover, it has an advantage for long-term energy security because the basic technology of the metallic fuel fast reactor cycle is also applicable to the future sustainable nuclear energy supply system.

For these reasons, Toshiba is developing a system to reduce nuclear waste burden using a TRU burner as shown in Fig. 15.1. The system is characterized by a closed fuel cycle that encompasses the following main facilities: fuel manufacturing plant to fabricate uranium-free TRU metallic fuel and LLFPs target from TRU and LLFPs extracted from LWR spent fuel, a fast reactor to burn those fuels, and recycling facilities to reprocess and refabricate the spent fuel from the fast reactor by pyro-processing. Although substances remain after reprocessing that must finally be disposed outside the cycle, their toxicity and radioactivity are diminished to the same level as those of natural uranium by enhancing burning and processing rates and storing them for a few hundred years within the system. Among the aforementioned facilities in the system, this study focuses on the TRU-burning fast reactor and investigates the practicability of the uranium-free TRU metallic fuel core.

2 Issues and Measures Against the Uranium-Free TRU Metallic Fast Reactor Core

This chapter presents issues and measures against the uranium-free TRU metallic fast reactor core. Also, the targets and constraints in parametric survey and selection of core and fuel specification are briefly described.

There are two main issues associated with the TRU burning fast reactor cycle using uranium-free metallic fuel in terms of practicability:

-

(1)

Decrease in the absolute value of the negative Doppler reactivity coefficient resulting from absence of uranium-238, which has the ability to absorb neutrons at elevated temperatures. example,

-

metallic fuel with uranium: −1 × 10−3 Tdk/dT

-

metallic fuel without uranium: −6 × 10−4 Tdk/dT

-

-

(2)

Increase in burn-up reactivity swing as fissile decreases monotonically in uranium-free core. example,

-

metallic fuel with uranium: ~1 %dk/kk′/150 days

-

metallic fuel without uranium: ~6 %dk/kk′/150 days

-

To solve these issues, there are several candidates, as follows:

-

(1)

Enhance Doppler feedback

-

Introduce diluent material in the metallic fuel

-

Introduce spectrum moderator

-

-

(2)

Reduce burn-up reactivity swing

-

Reduce the core height

-

Introduce neutron absorber outside the core

-

Increase the number of refueling batches

-

Generally, if it is conventional fast reactors with U-Pu fuel, the burn-up reactivity swing depends mainly on decrease of fissile amount and increase of neutron parasitic capture of fission products and actinides from burn-up. Therefore, the typical ways to reduce burn-up reactivity swing are to increase conversion ratio via fissile enrichment reduction and to reduce neutron parasitic capture. Here, the conversion ratio is defined as the amount of fissile materials production divided by the amount of neutron absorption, that is, fission and capture, and natural decay of fissile materials. It is difficult, however, for a uranium-free core to increase the conversion ratio because fissile enrichment cannot be controlled in the absence of uranium. Although the reduction of neutron parasitic capture by neutron spectrum hardening improves burn-up reactivity swing, it also harms the Doppler effect. For these reasons, when it comes to uranium-free core, increase of the fissile amount at the beginning of the cycle makes sense because it reduces the ratio of the fissile consumption to the fissile amount at the beginning of the cycle.

These candidates were parametrically surveyed to evaluate the feasibility of the uranium-free TRU metallic fuel fast reactor core in light of aforementioned issues. The targets assumed were the core performances with the Doppler reactivity coefficient equivalent to a conventional U-Pu metallic fuel core. Furthermore, constrains associated with fuel fabrication such as melting temperature was taken into consideration because, in this evaluation, diluent material was assumed to be used as a fuel slug alloy, not cladding material. Hence, the slug was assumed be fabricated by injection casting as the same as the conventional metallic fuel. This step makes the allowable maximum melting temperature of the fuel alloy less than 1,200 °C to prevent Am volatilization during injection casting [12].

3 Parametric Analysis on the Effect of Measures

This chapter describes parametric analysis methodology and analysis results for Doppler feedback enhancement and burn-up reactivity swing reduction.

3.1 Parametric Analysis Methodology

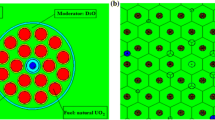

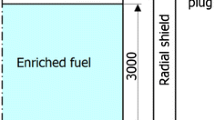

A hypothetical 300 MWe fast reactor core was used for the parametric survey to enhance Doppler feedback and burn-up reactivity swing. Table 15.1 and Fig. 15.2 show the assumed core conditions and RZ geometry for parametric survey, respectively. The calculation methods were as follows. Core burn-up characteristics were analyzed with the burnup calculation code STANBRE [13]. Reactivity coefficients were analyzed using the diffusion calculation code DIF3D [14]. The effective cross sections used in these calculations were obtained by the cell calculation code SLAROM-UF [15], based upon 70 group cross sections from JENDL-4.0 [16] with a self-shielding factor table as a function of background cross section. This method for the production of the effective cross sections is considered to be adequate to take into account the influence of each diluting material upon the self-shielding effect of heavy isotopes for the parametric study. Concerning material compositions, a homogeneous model of fuel, diluent, and spectrum moderator was used.

To begin with, in the survey to improve Doppler feedback, 21 elements to enhance resonance absorption were evaluated as a diluent material for the TRU alloy: Cr, Mn, Fe, Ni, Nb, Mo, Tc, Ru, Rh, Pd, Nd, Sm, Gd, Tb, Dy, Er, Tm, Ta, W, Os, and Au. Moreover, the effect by neutron moderators such as BeO, 7Li2O, 11B4C (100 % enrichment of 11B was assumed), and ZrH2 were investigated to clarify the impact against Doppler feedback by neutron spectrum softening. To compare the Doppler effect enhancement of various diluent materials and neutron spectrum moderators in a simple manner, each material was hypothetically added to TRU-10wt%Zr alloy. The amount of each material added was adjusted case by case to maintain 1.0 of k-effective at the end of cycle.

Next, in the evaluation to decrease the burn-up swing, the effects of the measures taken to increase the fissile amount at the beginning of the cycle were studied. The effects on burn-up reactivity swing were evaluated by reducing the core height, installing B4C shield at core peripheral, and increasing the number of refueling batches, which all lead to increase of the fissile amount at the beginning of the cycle.

Last, reflecting the results obtained by the parameter surveys, an optimal uranium-free TRU metallic fuel core was specified, and its feasibility in light of Doppler feedback and burn-up swing was evaluated by core performance analysis.

3.2 Analysis Results for Doppler Feedback Enhancement

The effects of measures taken to enhance Doppler feedback, that is, diluent and spectrum moderator, are evaluated in this section.

As shown in Fig. 15.3, 6 among 21 diluent materials are found to enhance Doppler feedback more than Zr, the typical metallic fuel alloy. Although Nb, Ni, W, Mo, Fe, and Cr have greater potential to enhance Doppler feedback than Zr, there are some deficiencies that cannot be ignored. First, the melting points of Pu-Ni alloy and Pu-Fe alloy are below 500 °C, which is too low for nuclear fuel [17]. Second, the melting point of Pu-W alloy is too high to fabricate fuel by injection casting because the melting temperature of W itself is above 3,000 °C. Third, the allowable contents of Mo and Nb in the metal fuel alloy are too small to enhance the Doppler coefficients, which are 5 wt% and 3 wt%, respectively, under the condition to maintain their melting temperatures below 1,200 °C to prevent Am vaporization during injection casting [18]. Finally, the number of past experiences with Cr, for example, irradiation testing of Pu-Cr alloy, is less than enough to employ it as a diluent material for uranium-free fuel. Consequently, Zr was chosen as the fuel diluent material.

Then, as shown in Fig. 15.4, the absolute value of the negative Doppler coefficient remarkably increased by introducing a spectrum moderator such as BeO, 11B4C, or ZrH2. The adoption of ZrH2, however, may cause dissociation of hydrogen upon accident. Besides, the usage of 11B4C is costly because almost 100 % enrichment of 11B is necessary to enhance Doppler feedback significantly. Therefore, BeO was selected as a moderator material for the uranium-free core.

3.3 Analysis Results for Burnup Reactivity Swing Reduction

This section evaluates the effects of measures taken to reduce burnup reactivity swing of the uranium-free TRU metallic fuel core. In the parameter surveys, the operation cycle length, that is, 150 days, the core volume, and the core power density were kept constant to compare the effect of each countermeasure. The average fuel burnup was also kept constant, save for the survey of the number of refueling batches. The adjusting parameter to increase the fissile amount was the zirconium content in TRU-Zr alloy fuel to keep k-effective = 1.0 at the end of the cycle.

Table 15.2 shows the summary of the analysis results. The reduction of the core height from 93 cm to 65 cm resulted in a 12 % decrease of burn-up reactivity swing. The introduction of a B4C shield, where natural boron was assumed, at the core periphery region resulted in only about a 5 % decrease in burn-up reactivity swing. On the other hand, the penalty of this countermeasure is the increase of core power peaking because the leakage of neutrons from the core surface increases. Hence, this measure was not adopted in the subsequent core design. Regarding the effect of the number of refueling batches, the larger is the number of refueling batches, the smaller the burn-up reactivity swing becomes. The effect was approximately a 5 % decrease in burnup reactivity swing for a 40 % increase in the number of refueling batches. This measure was not adopted in the subsequent core design because its effect on the burn-up reactivity swing is small and it leads to significant increase of core power peaking because of the increased difference of burn-up between most burnt fuel and fresh fuel.

4 Developed Uranium-Free TRU Metallic Core

This chapter describes specifications for selection of a uranium-free TRU metallic core and performance of the uranium-free TRU metallic core. Then, the core and fuel are developed on the basis of those results and the feasibility of the developed core is evaluated.

4.1 Specification Selected for Uranium-Free TRU Metallic Core

On the basis of the results of the parametric surveys, the uranium-free TRU burning core was specified as shown in Table 15.3 and Fig. 15.5. TRU-Zr alloy fuel pins and BeO pins were employed to enhance the Doppler coefficient. The reason for adopting the TRU-Zr alloy fuel is to use a simpler fuel fabrication method, that is, injection casting, in contrast to a TRU-Zr particle fuel in a zirconium metal matrix. Then, the zirconium content in TRU-Zr alloy was assumed to be limited below 35 wt% to keep the melting point of the TRU-Zr alloy below 1,200 °C to prevent Am vaporization during injection casting [19]. The fuel pins and the BeO pins were separately located in the fuel subassemblies (Fig. 15.6). The diameter of fuel pins was reduced from 0.65 to 0.48 cm to compensate for the increase of the average linear heat rate caused by employment of the BeO pins. Core height is 65 cm to reduce burn-up reactivity swing, whereas the core diameter was increased from 180 to 250 cm to keep the linear heat rate of the fuel pin similar to the 93-cm-height core. The operation cycle length is 150 days, which can be controlled by conventional control rods and fixed neutron absorbers.

4.2 Performance of the Uranium-Free TRU Metallic Core

The core performance of the developed uranium-free core was evaluated as shown in Table 15.4. The Zr content in the fuel alloy was determined to maintain criticality during the operation cycle under the conditions of the upper limit of the melting point, 1,200 °C. According to the results, the uranium-free TRU metallic core is viable in terms of core performance, safety performance, fuel fabrication, and TRU burner.

The Doppler coefficient is similar to that of the conventional metallic fuel fast reactor cores, and the burn-up reactivity swing is considered to be controllable by conventional control rods and fixed absorbers. Moreover, core sodium void reactivity including the upper plenum region is negative because of neutron leakage at the upper plenum region and neutron spectrum moderation from the presence of BeO during sodium voiding. Although the restriction for sodium void reactivity was not assumed for the core in this study, low sodium void reactivity is a significant factor for sodium-cooled fast reactors.

Furthermore, the developed core design has the potential to achieve passive safety features against unprotected events such as unprotected loss of flow (ULOF) and unprotected transient overpower (UTOP) similar to a conventional metallic fuel core because the basic core safety parameters, that is, average and peak linear heat rates for lower fuel temperatures, the enhanced Doppler coefficient, and low sodium void coefficient (negative sodium coefficient in whole core), were maintained within the similar ranges of a conventional metallic fuel core design [20].

Feasibility in the light of decay heat is also confirmed to be practicable, as the decay heat of the fresh fuel material is 32 W/kgHM, which is less than 10 % of that of the minor actinide (MA)-only fuel. Also, the decay heat of the fresh fuel subassembly is approximately 240 W. Taking advantage of some cooling scheme such as air flow, this fuel can be fabricated as a fuel pin bundle [21].

Moreover, the results also shows the profitability of the uranium-free TRU metallic fuel fast reactor itself, because a 1-year operation of this 300 MWe TRU-burning fast reactor burns 260 kg TRU, corresponding to the amount produced by a 1.2 GWe-year operation of a conventional LWR.

For all these reasons, the TRU-burning fast reactor using uranium-free TRU metallic fuel is considered to be feasible. Further study such as reduction of burn-up reactivity swing and trade-off of various countermeasures considering economic aspect helps improve and optimize the core design in the next phase.

5 Conclusions

A TRU transmutation system associated with the uranium-free metallic fuel fast reactor is a practical way to burn TRU with sustainability, fewer R&D needs, and a simple system, because it can be used as both a TRU burner and a power supply plant. Employment of pyro-processing for recycling reduces the burden of R&D requirements, and introduction of a conventional fuel fabrication method and pyro-processing allows less complex facilities.

In this study, two main issues related to the uranium-free core were investigated and discussed to clarify the feasibility of a TRU-burning fast reactor cycle using such a core: Doppler coefficient for reactor safety, and burn-up reactivity swing for acceptable reactor operating cycle length.

The results show that the uranium-free fast TRU fast reactor core is viable because those issues can be solved by TRU-Zr alloy fuel, BeO neutron moderator, and reduced core height. Thanks to the BeO pins that function not only as a neutron moderator but also as a diluent material, the 35 %Zr alloy fuel can be fabricated without Am vaporization because its melting point is maintained below 1,200 °C, the temperature that causes Am vaporization during injection casting fuel fabrication. Moreover, the decay heat of the fresh fuel is considered to be an acceptable level for the fuel fabrication. Also, a 1-year operation of this 300 MWe core burns the TRU that is produced by 1.2 GWe-year operation of a conventional LWR.

In conclusion, the prospect of a TRU-burning fast reactor cycle using uranium-free metallic fuel was confirmed. Further study, not only to improve core performances but also to develop a recycling process associated with this uranium-free system, which is currently under way, promotes realization of the system.

References

Yamashita T, Kuramoto K-I, Akie H, Nakano Y, Nitani N, Nakamura T, Kusagaya K, Ohmichi T (2002) Rock-like oxide fuels and their burning in LWRs. J Nucl Sci Technol 39(8):865–871

Miwa S, Osaka M, Usuki T, Sato I, Tanaka K, Hirosawa T, Yoshimachi H, Onose S (2011) MgO-based inert matrix fuel for a minor actinide recycling in a fast reactor cycle. In: Proceedings of Global 2011, Makuhari, Japan, Dec 11–16, 2011

Messaoudi N, Tommasi J (2002) Fast burner reactor devoted to minor actinide incineration. Nucl Technol 137:84–96

Hill RH, Khalil HS (2000) Physics studies for sodium cooled ATW blanket. In: Proceedings of the IAEA technical committee meeting on core physics and engineering aspects of emerging nuclear energy systems for energy generation and transmutation. Argonne National Laboratory

Beller DE, Van Tuyle GJ, Bennett D, Lawrence G, Thomas K, Pasamehtoglu K, Li N, Hill D, Laidler J, Finck P (2001) The U.S. accelerator transmutation of waste program. Nucl Instrum Methods Phys Res A 463:468–486

Heidet F, Kim TK, Taiwo TA (2013) Multiple-stage fuel cycle options based on subcritical systems. In: Proceedings of the 2013 ANS Winter Meeting, Washington, DC, November 10–14, 2013

Meyer MK et al (2001) Fuel design for the U.S. accelerator driven transmutation system. Nuclear Application in the New Millennium (accApp-ADITTA ‘01), Reno, Nov 2001

Carmack WJ et al (2009) Metallic fuels for advanced reactor. J Nucl Mater 392:139–150

Stevenson CE (1987) The EBR-II fuel cycle story. American Nuclear Society, La Grange Park, Illinois, USA

Arie K, Kawashima M, Araki Y, Sato M, Mori K, Nakayama Y, Ishiguma K, Fujiie Y (2007) The sustainable system for global nuclear energy utilization. In: GLOBAL 2007, Boise, ID, September 9–13, 2007

Arie K, Kawashima M, Oomori T, Okita T, Kotake S, Fujiie Y (2013) Role of fast reactor and its cycle to reduce nuclear waste burden, In: GLOBAL 2013, Salt Lake City, UT, September 29–October 3, 2013

Hayes S et al (2009) Status of transuranic bearing metallic fuel development. In: Global 2009, Paris, September 6–11, 2009

OECD-NEA (2000) Nuclear Energy Agency, Organisation for Economic and Co-operation Development (NEA, OECD), Paris, France

Derstine KL (1984) DIF3D: a code to solve one-,two- and three-dimensional finite difference diffusion theory problems. ANL-82-64, Argonne National Laboratory

Hazama T et al (2009) SLAROM-UF: ultra fine group cell calculation code for fast reactor: version 20090113. JAEA-Review 2009-003

Shibata K, Iwamoto O, Nakagawa T, Iwamoto N, Ichihara A, Kunieda S, Chiba S, Furutaka K, Otuka N, Ohsawa T, Murata T, Matsunobu H, Zukeran A, Kamada S, Katakura J (2011) JENDL-4.0: a new library for nuclear science and engineering. J Nucl Sci Technol 48(1):1–30

Kittel JH et al (1971) Plutonium and plutonium alloys as nuclear fuel materials. Nucl Eng Des 15:373–440

ASM Alloy Phase Diagram Center (2007) ASM International, Materials Park. (http://www.asminternational.org/AsmEnterprise/APD)

Hecker SS, Stan M (2008) Properties of plutonium and its alloys for use as fast reactor fuels. J Nucl Mater 383:112–118

Wade DC, Fujita EK (1989) Trends versus reactor size of passive reactivity shutdown and control performance. Nucl Sci Eng 103:182

Kawaguchi K et al (2007) Conceptual study of measures again heat generation for TRU fuel fabrication system. In: Global 2007, Boise, ID, September 2007

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

This chapter is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

Copyright information

© 2015 The Author(s)

About this chapter

Cite this chapter

Ishii, K. et al. (2015). Development of Uranium-Free TRU Metallic Fuel Fast Reactor Core. In: Nakajima, K. (eds) Nuclear Back-end and Transmutation Technology for Waste Disposal. Springer, Tokyo. https://doi.org/10.1007/978-4-431-55111-9_15

Download citation

DOI: https://doi.org/10.1007/978-4-431-55111-9_15

Published:

Publisher Name: Springer, Tokyo

Print ISBN: 978-4-431-55110-2

Online ISBN: 978-4-431-55111-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)