Abstract

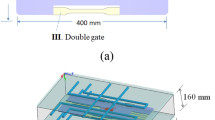

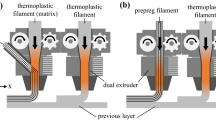

The injection moulding of fibre-reinforced plastics leads to a flow related characteristic microstructure with fibres aligned in flow direction in the shell layers and fibres aligned transversely to the flow direction in the core layer. The combination of a design related gate location and the flow related microstructure can lead to an unfavourable fibre orientation. For example, the flow direction for rotationally symmetric parts under internal pressure is often in axial direction and therefore the main fibre orientation is transversely aligned to the critical tangential tension. This leads to high wall thicknesses, increase in weight and material inefficiency. This paper shows first results of the targeted manipulation of the fibre orientation for long and short fibre reinforced thermoplastics through relative movement. The relative movement of opposing mould surfaces is realised through a rotating core in the injection mould and allows the reorientation of the fibres in tangential direction through shearing of the melt. The evaluation of this process is done by mechanical tests, microscopic investigations and computed tomography scans and shows a significant increase of transversely aligned fibres.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Flepp, A.: Optimal für den Motor. Kunststoffe 8(2015), 86–89 (2015)

Baleno, B., Holtzberg, M.: Der kunststoffintensive Motor. Kunststoffe 3(2016), 28–32 (2016)

Schmachtenberg, E., Brandt, M., Menning, G., et al.: Faserverstärkung richtig simulieren. Kunststoffe 5(2004), 94–99 (2004)

Johannaber, F., Michaeli, W.: Handbuch Spritzgießen, 2nd edn. Hanser, München (2014)

Schoßig, Marcus: Schädigungsmechanismen in faserverstärkten Kunststoffen, 1st edn. Vieweg+Teubner, Wiesbaden (2011)

Dehennau, C., Leo, V., Cuvelliez, C.: Process for moulding a thermoplastic material by injection onto a rotating core. US Patent 5,798,072, publication date 1998/08/25

Dehennau, C., Leo, V., Cuvelliez, C.: Process for moulding a thermoplastic material by injection onto a rotating core. US Patent 5,824,254, publication date 1998/10/20

Dehennau, C., Leo, V., Cuvelliez, C.: Process for moulding a thermoplastic material by injection onto a rotating core. DE Patent 69613283T2, publication date 2002/04/18

Warkoski, G.: Das Spritzgießen von verstärkten Polymeren mit rotierendem Kern. Gummi Fasern Kunststoffe GAK 7(2006), 439–443 (2006)

ASTM 2290: Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method. ASTM International, West Conshohocken, USA (2003)

Acknowledgments

The authors acknowledge the financial support by the Federal Ministry for Economic Affairs and Energy of Germany in the project Werkzeugsystem mit drehendem Kern (project number ZF4153401LL5). We would like to thank H. Sundermeier GmbH, Hüllhorst, Germany, for their active work as cooperation partner in this project. Further thanks goes to the companies Arburg GmbH & Co KG, Loßburg, Germany, for the provision of an injection moulding machine and EMS-Chemie AG, Domat/EMS, Switzerland and A. Schulman, Inc., Fairlawn, USA for support with material. At last, we would like to thank Mr. Uwe Becker, Managing Director of MKS-Kunststoffspritzguss GmbH, Iserlohn, Germany, for the advisory support in the project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer-Verlag GmbH Germany, part of Springer Nature

About this paper

Cite this paper

Land, P., Krumpholz, T. (2020). Targeted Manipulation of Fibre Orientation Through Relative Movement in an Injection Mould. In: Hopmann, C., Dahlmann, R. (eds) Advances in Polymer Processing 2020. Springer Vieweg, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-60809-8_10

Download citation

DOI: https://doi.org/10.1007/978-3-662-60809-8_10

Published:

Publisher Name: Springer Vieweg, Berlin, Heidelberg

Print ISBN: 978-3-662-60808-1

Online ISBN: 978-3-662-60809-8

eBook Packages: EngineeringEngineering (R0)