Abstract

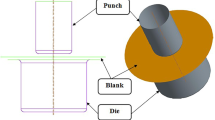

Forging is the process whereby the shape of a workpiece (usually metallic) is changed by pressing or hammering the workpiece between two or more dies, with or without the application of heat. Complex shapes are usually forged from the original stock material in a number of stages. Quite often, the dies for several stages are grouped together in the same forging press or hammer, the workpiece being transferred from die cavity to die cavity (manually or by an automatic mechanism) in between successive blows of the machine.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Yu GB, Dean TA. A CAD/CAM package for hammer forging dies. In: Proceedings 25th Machine Tool Design Research Conference, Birmingham, April 1985. Macmillan, London, 1985, pp 459–464

Choi SH, Sims P, Dean TA. A complete CAD/CAM package for hammer forging dies. Proceedings 25th Machine Tool Design Research Conference, Birmingham, April 1985. Macmillan, London, 1985, pp 451–458

Gokler MI, Dean TA, Knight WA. Computer aided die design for upset forging machines. Proceedings 11th NAMRC Conference, 1983, pp 217–223

Rao SS. The finite element method in engineering, Pergamon, 1982

Pillinger I. The prediction of metal flow and properties in three-dimensional forging using the finite-element method. PhD thesis, University of Birmingham, 1984

Pillinger I, Hartley P, Sturgess CEN, Rowe GW. Finite-element modelling of metal-flow in three-dimensional forming. Int J Num Meth Eng, 1988; 25: 87–97

Rowe GW, Sturgess CEN, Hartley P, Pillinger I. Finite-element plasticity and metalforming analysis. Cambridge University Press, 1990

Hartley P, Sturgess CEN, Dean TA, Rowe GW, Eames AJ. Development of a forging expert system. In: Pham DT (ed) Expert systems in engineering. IFS, Bedford, 1988, pp 425–443

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1991 Springer-Verlag London Limited

About this chapter

Cite this chapter

Pillinger, I., Hartley, P., Sturgess, C.E.N., Dean, T.A. (1991). An Intelligent Knowledge-Based System for the Design of Forging Dies. In: Pham, D.T. (eds) Artificial Intelligence in Design. Artificial Intelligence in Industry Series. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-74354-2_13

Download citation

DOI: https://doi.org/10.1007/978-3-642-74354-2_13

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-74356-6

Online ISBN: 978-3-642-74354-2

eBook Packages: Springer Book Archive