Abstract

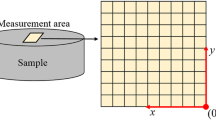

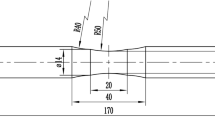

In this paper, the machining texture and shot peening (SP) on the fatigue properties of a high-strength TC18 titanium alloy for aviation were studied. The surface texture, surface morphology, hardness distribution, and residual stress characteristics of fatigue specimens were analyzed by using scanning electron microscopy (SEM), micro-hardness tester, and X-ray diffraction residual stress analyzer. The results showed that the fatigue life of the axial texture processing was 27 % lower than that of the axial polishing specimens (BM) . But circumferential texture processing was 72 % lower than that of BM. It was attributed that the fatigue cracks was initiation easily by circumferential texture processing. Then, SP technology was induced to repair the fatigue life of the circumferential texture processing specimens. Compared with the BM specimens, the fatigue life of SP specimens increased approximately 12 times. That was attributed to the depth of compressive residual stress field induced by SP.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ulutan D, Ozel T (2011) Machining induced surface integrity in Titanium and Nickel Alloys: a review. Int J Mach Tool Manuf 51:250–280

Boyer PR, Briggs RD (2005) The use of β Titanium Alloys in the Aerospace Industry. J Mater Eng Perform 14:681–685

Wang X, Gao Y, Wang Q et al (2012) Effect of re-shot-peening on the fatigue life of TC18 Titanium Alloy. J Mater Eng (2):67–71 (in Chinese)

Javidi A, Rieger U, Eichlseder W (2008) The effect of machining on the surface integrity and fatigue life. Int J Fatigue 30:2050–2055

Suraratchai M, Limido J, Mabru C et al (2008) Modelling the influence of machined surface roughness on the fatigue life of Aluminium Alloy. Int J Fatigue 30:2119–2126

Wang CY, Xi WJ (2012) Investigation on notch sensitivity of TC18 Titanium Alloy. Rare Metal Mater Eng 41:663–666

Zhang XH, Liu DX (2009) Effect of shot peening on fretting fatigue of Ti811 Alloy at elevated temperature. Int J Fatigue 31:889–893

Liu DX, He JW (2001) Effect of shot peening factors on fretting fatigue resistance Titanium Alloy. Acta Metall Sin 37:156–160 (in Chinese)

Xie L, Jiang C, Lu W (2011) Investigation on the residual stress and microstructure of (TiB + TiC)/Ti–6Al–4V composite after shot peening. Mater Sci Eng, A 528:3423–3427

Mylonas GI, Labeas G (2011) Numerical modelling of shot peening process and corresponding products: residual stress, surface roughness and cold work prediction. Surf Coat Technol 205:4480–4494

Du DX, Liu DX, Meng BL et al (2013) Effects of pretreatment and HVOF sprayed cermet coating on fatigue properties of TC21 Titanium Alloy. Sci China Technol Sci 56:1029–1037

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51171154, 51101127).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Du, D., Liu, D., Xiang, D., Meng, B., Zhang, X. (2014). Repair of Shot Peening on Fatigue Properties of High-Strength TC18 Titanium Alloy for Aviation. In: Wang, J. (eds) Proceedings of the First Symposium on Aviation Maintenance and Management-Volume II. Lecture Notes in Electrical Engineering, vol 297. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-54233-6_63

Download citation

DOI: https://doi.org/10.1007/978-3-642-54233-6_63

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-54232-9

Online ISBN: 978-3-642-54233-6

eBook Packages: EngineeringEngineering (R0)