Abstract

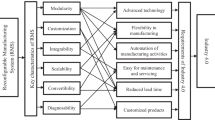

The need for a new generation of more responsive manufacturing enterprises (MEs) has emerged where trading uncertainties have triggered complex causal impacts that necessitate faster, better and cheaper production. In today’s hostile market driven world, most MEs need to be reconfigurable by deploying flexible resources that are flexibly bound together into systems via the use of suitable organisational structures. It follows that MEs can compete by deploying organisational structures that are more readily reconfigured than those of competitor MEs. The literature reports on alternative manufacturing philosophies that any given ME can adopt (such as Lean, Agile, Postponement and Economies of Scope & Scale) and managers and engineers responsible for MEs can reference these ideas so as to balance response, cost and quality trade offs throughout their enterprise. Therefore based upon a literature analysis, this paper describes key requirements of next generation reconfigurable MEs. Also a research framework is proposed to address common reconfiguration problems in MEs. The paper also provides an overview of findings when applying that framework in automotive, furniture, and bearings industries. Reflections, conclusions, and recommendation for future research are also included.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Mehrabi, M.G., Ulsoy, A.G. and Koren, Y. (2000): Reconfigurable manufacturing systems: key to future manufacturing, in: Journal of Intelligent Manufacturing, Vol. 11, No. 4, pp. 403-419.

ElMaraghy, H. (2009): Changeable and reconfigurable manufacturing systems, Springer, London.

Koren, Y., Heisel, U., Jovane, F., Moriwaki, T., Pritschow, G., Ulsoy, G. and Van Brussel, H. (1999): Reconfigurable Manufacturing Systems, in: Annals of the CIRP, Vol. 48, No. 2, pp. 527-540.

The Manufacturer. (2006): Globalization Survey of US for year 2005, from http://www.themanufacturer.com/.

DTI (2004): Review of the government's manufacturing strategy two years on London, UK Department for Trade and Industry.

Weston, R.H., Chatha, K.A. and Ajaefobi, J.O. (2004): Process thinking in support of system specification and selection, in: Advanced Engineering Informatics, Vol. 18, No. 4, pp. 217-229.

Monfared, R.P. (2009): Enterprise Modelling: A Component- Based Approach to Design and Construction of Change Capable Manufacturing Cell Control Systems, VDM Verlag, Saarbrücken-Germany.

Gunasekaran, A. and Yusuf, Y.Y. (2002): Agile manufacturing: a taxonomy of strategic and technological imperatives, in: International Journal of Production Research, Vol. 40, No. 6, pp. 1357–1385.

Lee, S.-M., Harrison, R. and West, A.A. (2004): A componentbased distributed control system for assembly automation, in: Proceedings of the 2nd IEEE International Conference on Industrial Informatics (INDIN'04), pp. 1-33, Berlin, Germany.

Gunasekaran, A. (1998): Agile manufacturing: enablers and an implementation framework, in: International Journal of Production Research, Vol. 36, No. 5, pp. 1223-1247.

US National Research Council (1998): Visionary Manufacturing Challenges for 2020, National Academy Press, Washington, D.C.

ASMC and MPI (2009): Next Generation Manufacturing Study Overview and Findings, USA, American Small Manufacturers Coalition (ASMC) and Manufacturing Performance Institute (MPI), pp. 1-52.

US National Science and Technology Council (2008): Manufacturing the Future: Federal Priorities for Manufacturing Research and Development, USA, Interagency Working Group on Manufacturing R&D Committee on Technology, pp. 89.

Stevenson, M., Hendry, L.C. and Kingsman, B.G. (2005): A review of production planning and control: the applicability of key concepts to the make-to-order industry, in: International Journal of Production Research, Vol. 43, No. 5, pp. 869–898.

Rahimifard, A. and Weston, R.H. (2007): The enhanced use of enterprise and simulation modelling techniques to support factory changeability, in: International Journal of Computer Integrated Manufacturing, Vol. 20, No. 4, pp. 307-328.

Vernadat, F.B. (2002): Enterprise modeling and integration (EMI): Current status and research perspectives, in: Annual Reviews in Control, Vol. 26, No. 1, pp. 15-25.

Chen, D., Doumeingts, G. and Vernadat, F. (2008): Architectures for enterprise integration and interoperability: Past, present and future, in: Computers in Industry, Vol. 59, No. 7, pp. 647-659.

Berio, G. and Vernadat, F. (2001): Enterprise modelling with CIMOSA: functional and organizational aspects, in: Production Planning & Control: The Management of Operations, Vol. 12, No. 2, pp. 128-136.

CIMOSA Association. (2009): European projects on enterprise modelling, Retrieved 10 Mar, 2009, from http://www.cimosa.de/Modelling/Modelling1.html.

Kosanke, K., Vernadat, F. and Zelm, M. (1999): CIMOSA: Enterprise engineering and integration, in: Computers in Industry, Vol. 40, No. 2, pp. 83-87.

Masood, T. (2009): Enhanced Integrated Modelling Approach to Reconfiguring Manufacturing Enterprises, Wolfson School of Mechanical and Manufacturing Engineering, Loughborough University, Loughborough, PhD Thesis, p. 314.

Mintzberg, H. and Heyden, L.V.d. (1999): Organigraphs: Drawing How Companies Really Work, in: Harvard Business Review, No. 99506, pp. 87-94.

Weston, R.H. (1999): Reconfigurable, component-based systems and the role of enterprise engineering concepts, in: Computers in Industry: Special issue on CIM open systems architecture evolution and applications in enterprise engineering and integration, Vol. 40, No. 2-3, pp. 321-343.

Masood, T. and Weston, R. (2011): An integrated modelling approach in support of next generation reconfigurable manufacturing systems, in: International Journal of Computer Aided Engineering and Technology, Vol. 3, No. 3-4, pp. 372-398.

Masood, T., Weston, R. and Rahimifard, A. (2010): A computer integrated unified modelling approach to responsive manufacturing, in: International Journal of Industrial and Systems Engineering, Vol. 5, No. 3, pp. 287-312.

Zhen, M., Masood, T., Rahimifard, A. and Weston, R. (2009): A structured modelling approach to simulating dynamic behaviours in complex organisations, in: Production Planning & Control, Vol. 20, No. 6, pp. 496-509.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Masood, T., Weston, R. (2012). Enabling Competitive Design of Next Generation Reconfigurable Manufacturing Enterprises. In: ElMaraghy, H. (eds) Enabling Manufacturing Competitiveness and Economic Sustainability. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-23860-4_67

Download citation

DOI: https://doi.org/10.1007/978-3-642-23860-4_67

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-23859-8

Online ISBN: 978-3-642-23860-4

eBook Packages: EngineeringEngineering (R0)