Abstract

The reduction of CO2 emission from cement industry represents a priority task in the roadmap defined for the year 2020 by the European Union (EU) Commission for a resource efficient Europe. Several research projects have been undertaken aimed at developing non-hazardous materials as partial substitute of clinker in cement formulations, but also new, low-carbon, cements fully replacing clinker. Among the new cementing materials, Si–Al geopolymers seem the most promising, in terms of CO2 emission and mechanical and thermal properties. In this chapter, mechano-chemical processing of kaolin clays to produce metakaolin (MKA) for the synthesis of Si–Al geopolymers is proposed as an alternative process to replace thermal treatments performed at 650–850 °C. Results obtained show that the mechano-chemical process is also suitable to make low cost blended Si–Al geopolymers where 40% of MKA is replaced by mechano-chemically activated volcanic tuffs. The compatibility of mechano-chemistry with industrial production was investigated by building a prototype milling system that was tested in a small industrial facility producing zeolites from industrial wastes. The degree of automation allowed the prototype to work unattended for 10 months. Based on the results obtained from these tests, a milling system for a full scale production of mechano-chemically activated rock materials was designed, and its performances analysed.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

1 The Importance of Manufacturing Industry, Global Perspective

The reduction of CO2 from industrial processes is a priority task in the roadmap defined for the year 2020 by the European Union (EU) Commission for a sustainable Europe [1]. In the EU countries most of the CO2 emission comes from sectors belonging to the Emission Trading System (ETS), where cement industry is one of the most important. The case of Italy is paradigmatic, because with 0.35 Mt y−1 of CO2 [2], Italy is one of the major CO2 emitting countries in Europe, and is ranked as 19th in the world. While the targets fixed for the year 2020 in the reduction of CO2 emission from non-ETS sectors have been already met by Italy, those fixed from industrial activities of the ETS sector are still far to reach, since Italy is the second cement producer in Europe [3]. High emission of CO2 occurs in cement production, because the primary component of cement used in building industry is clinker, obtained by heating at 1,450 °C stoichiometric mixtures of carbonate and aluminosilicate rocks in rotary kilns. Although CO2 emission from fuel combustion is relevant, that produced by thermal decomposition of Ca(CO3) in carbonate rocks is the most important.

To reduce CO2 emission, the European Cement Association [4] suggests to replace part of the clinker with supplementary cementitious materials (SCM), with a high pozzolanic activity. The most suitable ones are some industrial wastes, such as carbon fly-ashes, blast furnace slag, silica fume and rice husk, and natural materials, such as clay-rich or zeolite-rich rocks [4]. Larger emphasis has been given to the use of industrial wastes in blended cements [4] because this allows their safe recycling. Since the use of SCM depends upon the availability of wastes from other industrial sectors, not all countries can profitably adopt this practice. This is the main reason why in the last 5 years the Italian production of blended cements using 40–60% of industrial wastes was still limited to 3.6% [5]. By considering the large volcanic deposits of tuffs lithified by zeolites in Central-Southern Italy [6], it is not clear why the production of cements using natural pozzolanic materials is also limited to 12.6% in Italy. Indeed, 84% of the cement production in Italy is still made of cements with low SCM contents [5].

In the last 50 years, enormous efforts have been made to find new wastes acting as SCM, but also to find new cements for building industry. Among them, Si–Al geopolymers [7] are the most promising for the years to come, as they could fully replace the clinker-based ones. While clinker uses the hydraulic reaction to form a nano-material with randomly oriented hydrated calcium silicate crystals, different aluminosilicate materials can make cements by reacting in alkaline solutions, through the same pozzolanic reaction used by the ancient Romans to make concrete [7]. As shown by Davidovits [7], this approach is more flexible than the hydraulic one, because different 3D polymers can be obtained depending on the Si/Al ratio of the reagents, and the type of compensatory cations introduced in the randomly oriented nano-crystal structure of Si–Al geopolymers. Today, amorphous metakaolin (MKA) obtained by dehydration of kaolinite crystals (KA) in kaolin clays is, by far, the most used reagent for the synthesis of Si–Al geopolymeric cements, because it reacts faster than any other aluminosilicate rock material in alkaline solutions [7]. With respect to clinker-based cements, the use of MKA as primary reagent offers noticeable advantages in terms of CO2 emission, because it is obtained by heating kaolin clays at temperatures (600–850 °C) much lower than those used in clinker production. Since in the thermal treatment of kaolin clays CO2 emission almost exclusively comes from fuel combustion, Si–Al geopolymers are often termed as green cements. The most interesting aspect of MKA is that it can also be obtained at near ambient temperature and in a very short time by mechano-chemical processing of kaolin clays [8, 9]. Since milling systems are usually powered by electricity, CO2 emission can be further reduced in the production of Si–Al geopolymeric cements, by using renewable resources for electricity generation.

Until now the use of mechano-chemistry has been confined to a laboratory scale, because no adequate investigations have been made to assess the feasibility of this process at an industrial scale. In particular, data collected so far do not allow to develop industrial milling system for the production of this new type of cements. To fill this gap, a detailed study was undertaken to get the information required to make the industrial production of Si–Al geopolymers possible, through the mechano-chemical processing of rock materials necessary to produce them.

In this work, the grinding conditions necessary to obtain Si–Al geopolymers with good mechanical and thermal properties from kaolin clays and, for the first time, from volcanic tuffs, were investigated. The possibility to produce them at an industrial scale was studied by building a prototype system for the mechano-chemical treatment of rock materials, using the results obtained at a laboratory scale. Tests performed in a small industrial facility led to the design of a milling geometry for the mechano-chemistry of rock materials at an industrial scale, and it was possible to evaluate energy consumption required to activate them.

The chapter is organised as follows. Section 18.2 gives and overview of the state of the art and Sect. 18.3 presents the proposed approach. The development of Si–Al geopolymers from mechano-chemically treated rock materials is addressed in Sect. 18.4, the industrial aspects of this new technology are reported and discussed in Sects. 18.5 and 18.6. The conclusions are drawn in Sect. 18.7.

2 State of the Art

The amorphization of kaolinite (KA) crystals to produce MKA by mechano-chemical treatment of kaolin clays is known since long time [8], but is still confined to a laboratory scale, because the high energy requested by this phase transition can only be reached by mills, such as planetary ball mills, that are impossible to use for an industrial scale production. Several types of industrial mills for mineral treatment exist on the market, but their rotation speed is so small that they are unable to transmit a sufficiently high specific energy (≥6 J g−1 s−1) to kaolin particles, to fully amorphize KA crystals in a time shorter than 1 h. Because of this, they are used most for the comminution of rock materials with a large size range. The selection of the most suitable milling geometry for industrial application was thus fundamental in our research. Only having defined this, the milling parameters necessary to get the most reactive materials for the synthesis of Si–Al geopolymers could have been assessed through laboratory investigations performed on mills able to reproduce, at a smaller scale, the same grinding conditions existing in industrial mills. With this approach, data collected at a laboratory scale could have been used to assess the performance afforded by a mill for the industrial production of MKA, and other rock materials.

The amorphization of KA crystals illustrates well the number and type of parameters necessary to design a milling system for the synthesis of Si–Al geopolymers at an industrial scale. The energy required for this phase transition is, in fact, well known from the thermal treatment of kaolin clays, from which MKA is produced at an industrial scale. With the thermal treatment, the formation of MKA from kaolin clays strongly depends on temperature and time [7, 10,11,12]. The same is true with mechano-chemical processing, where MKA formation depends upon the grinding time [8, 9], if other parameters, such as the grinding ratio and the rotation speed of the moving bodies (ω) are constant. The grinding ratio plays an important role in the mechano-chemical processing of minerals, as it determines the time needed to induce phase transitions in the grinded material. Defined as the ratio M/m, where M is the mass of the moving bodies in the mill and m that of the material to grind, the grinding ratio inversely relates with the grinding time. The less material is grinded in a mill with a given mass M rotating at a given speed ω, shorter is the time to fully convert KA crystals into amorphous MKA. This inverse relation is easy to understand, because the less is the mass to grind, higher is the specific energy the crystals receive by collision. It must be noted that to convert KA into MKA at an industrial scale, grinding ratios not higher than approx. 250 can be used at a rotation speed of 1,500 r.p.m. in order to optimize the production. This means that a moving mass of 250 kg is needed to covert 1 kg of KA into MKA in the order of minutes. The huge mass of the moving bodies, combined with the high speed to which they must rotate, highlight the technological difficulties encountered in the construction of industrial mills for mechano-chemical treatment of minerals in rocks.

Another critical point is the wide interval of energy in which amorphous MKA exists. In this range, the glassy network of MKA evolves as a function of the energy, either thermal or mechanical, absorbed by the material [7, 10,11,12]. In particular, local structures with a mullite-like composition progressively form at high energy until γ-alumina and mullite crystallize from them [10, 11]. In the thermal treatment of kaolin clays, MKA starts to form at approx. 650–850 °C, whereas γ-alumina crystallizes above 1,000 °C [10, 11]. Since different amorphous structures are formed in the interval of existence of MKA, the most reactive and cost-effective must be identified. According to Davidovits [7], the highest reactivity is reached in MKA when the intensity of the band of 5 coordinated aluminium atoms (Al), indicated as Al(V), determined by 27Al Magic Angle Spinning Nuclear Magnetic Resonance (27Al MAS NMR), is higher than those of 4 and 6 coordinated Al, indicated as Al(IV) and Al(VI), respectively. This rule, which is still strictly followed by scientists working on the synthesis of geopolymers, has been questioned by some authors [12], who have raised doubts about its general validity. These doubts arise from recent observations indicating that also low reactive structures with mullite-like composition can generate an intense Al(V) band in MKA [13]. Because of this, results provided by 27Al MAS NMR MKA are not sufficient to identify the most reactive MKA structure, and also those provided by other techniques must be used. The combination of different techniques is also required because the energy to form MKA strongly depends upon the degree of disorder of KA crystals, which, in turn, depends on the impurities present in them. Differences between 100 and 200 °C have been actually observed in the formation of MKA by thermal treatment as a function of the degree of disorder of KA crystals [14]. Emphasis is given here to the mechano-chemistry of MKA, because this material is of great technological interest, since is also used for the synthesis of zeolites in alkaline environments [15]. While in the synthesis of zeolites no silicon (Si) sources are added to MKA, proper amounts of liquid alkali silicates must be added to the reaction mixture to make geopolymers with Si/Al ratio of 1, 2 or 3 [7]. Formation of zeolites from MKA further emphasizes the need of an industrial mill for the mechano-chemical treatment of KA in kaolin clays [16].

Since different types of geopolymers can be synthesized from MKA [7], a specific one needs to be selected to test the reactivity of thermally and mechano-chemically treated products. Poly-siloxo sialate (PSS) geopolymers with a Si/Al ratio equal to 2 are definitely the best candidates, because they exhibit the highest cementing properties for building applications [7]. In particular, those having K+ as compensatory cation (K-PSS from now on), combine a good mechanical resistance to unconfined uniaxial compression (UCS) with a very high thermal stability [7]. Melting temperatures higher than 1,400 °C have been reported for these geopolymers [7], against approx. 850 °C reached by clinker cements, although the UCS values usually fall in the same range (42–55 MPa). This means that also the thermal resistance of K-PSS geopolymers must be assessed to corroborate the high reactivity of MKA. This further emphasizes the need to certify Si–Al geopolymers obtained by mechano-chemical processing of kaolin clays with different techniques. Only through this approach it is, in fact, possible to define adequate protocols for quality assurance (QA) and quality control (QC) of geopolymers produced at an industrial scale with this process.

Mechano-chemical studies exist on the phase changes occurring in other rock materials than kaolin clays, but none of them refer to volcanic tuffs, although it has been shown that those cemented by zeolites exhibit a sufficient pozzolanic activity to act as SCM in clinker cements [17]. The possibilities afforded by the mechano-chemical treatment of these materials for the synthesis of K-PSS geopolymers were also investigated, by considering their low price with respect to that of kaolin clays.

3 Problem Statement and Proposed Approach

The selection of the milling geometry is fundamental to assess the feasibility of mechano-chemistry for the industrial production of Si–Al geopolymers. Definitely, the one with the lowest number of moving bodies rotating in a horizontal plane around a vertical axis, was the best suited for an industrial production, as it does not pose problems that cannot be solved with currently available technologies. Since this geometry does not substantially differ from that of ring mills used for mechano-chemical processing of materials at a laboratory scale, data collected with this type of mills could have been used to develop an automated grinding system for a small scale industrial production of MKA, and other activated materials. Based on the results obtained with the prototype, it was thus possible to design a milling system for a full scale production, using proper models.

Ring mills simulate well the kinematic motions of the type of mill better suited for industrial production, because they consist of a metal jar containing one or more concentric rings and a central cylinder as moving bodies, together with the material to grind. The jar is closed by a cover capable to maintain the motion of the colliding bodies in a horizontal plane, and keep the material inside the mill during grinding. A tight fixing of the jar with the metal housing obtained with O-rings, allows transferring an eccentric rotating motion to the mill from the shaft of an electric engine, whose speed can be controlled. As a function of the energy provided by the engine, the rings and cylinder, that are free to move inside the jar, can reach such a high centrifugal forces to induce phase transitions on the grinded material by collision. Pressures proportional to M and ω are generated between the moving bodies and the internal walls of the jar. The fact that ring mills with jars of 200 mL capable to reach a ω value of 1,500 r.p.m. were available on the market, provided a simple way to identify the optimal grinding conditions necessary to get a sufficient amount of reactive materials to synthesize Si–Al geopolymers from a commercial kaolin clay, and two volcanic tuffs. For modelling purposes, M/m ratios one order of magnitude lower than those commonly used in laboratory investigations were used in the ring mill. This allowed getting indications on the typical grinding time required in an industrial mill, and estimating the energy consumption necessary to produce a given mass of product from it.

A commercial kaolin clay, known to produce MKA with a high pozzolanic activity by thermal treatment, was selected as test material. Phase transitions occurring at increasing values of the grinding times were followed by looking at the structural changes in the grinded material. This was done by using X-ray powder diffraction spectroscopy (XRD), Fourier-transform infrared spectroscopy (FT-IR), X-ray fluorescence (XRF), X-ray photoelectron spectroscopy (XPS), 1H, 29Si and 27Al MAS NMR spectroscopy, and various types of thermo-gravimetric (TG) determinations, such as thermo-gravimetric analysis (TGA), differential-thermo-gravimetry (DTG), and differential thermal analysis (DTA). This, combined with the fact that the kinetic of MKA formation by thermal processing was also followed on the same test material, represented a distinctive feature of our study. Structural information provided in previous studies were, in fact, not detailed enough to unambiguously identify the conditions in which the most reactive and cost-effective MKA was formed. In our study, thermal and mechano-chemical transformations of kaolin clay were followed with a sufficient detail to know which MKA was the most suitable for the synthesis of K-PSS geopolymers. Proper amounts of liquid potassium silicate solutions with known composition (K-Sil), acting as supplementary source of K+ and Si, needed to be added to MKA and KOH [7] to get K-PSS geopolymers with a general formula reported in (18.1), where n is the degree of polymerization and y the number of water molecules coordinated by the structure.

Various formulations were thus tested with MKAs obtained with different processes to find those better approaching a Si/Al = 2.

Since geopolymers obtained from mechano-chemically and thermally treated MKAs exhibit different mechanical properties [9], only those with UCS falling in the range of commercial clinker cements (42–55 MPa) were tested for thermal resistance. Among them, only those melting at temperatures ≥1,400 °C were considered sufficiently competitive with clinker cements, to justify a production at an industrial scale. The structure and composition of K-PSS geopolymers was confirmed with the same techniques used for the characterization of MKA, to get products to be used as reference materials for the QA and QC of industrial products.

The same approach was followed to test the ability of pure and mechano-chemically treated volcanic tuffs cemented by zeolites (lithified tuffs) or glass (welded tuffs), to form K-PSS geopolymers. No thermal treatments were made on them, because the phase transitions of these rocks are too complex to follow, due the number and type of minerals present in them, and the presence of glass that melts at rather low temperatures.

Similarly to what is commonly done with clinker cements, the possibility to use mechano-chemically treated volcanic tuffs as SCM in the synthesis of Si–Al geopolymers was also investigated. This was done because zeolites contained in lithified tuffs have a sufficient pozzolanic activity to act as SCM in clinker cements [17]. The partial replacement of MKA with activated tuffs in Si–Al geopolymer production was considered an important aspect to investigate, because it could have dramatically reduced the cost of the final product, if the grinding time required to activate tuffs was much lower than that of MKA.

Data obtained with ring mills were used to build a prototype system with a sufficient degree of automation to be used in a small scale industrial facility. Since it was impossible to build a demonstration plant for geopolymer production, the prototype was tested in an industrial facility for zeolite production where mechano-chemical processing of minerals was requested for at least 3 months. In this way, enough data became available to design a milling system for industrial applications.

4 Si–Al Geopolymers from Mechano-Chemically Treated Rock Materials

The initial part of our study was devoted to define the optimal grinding parameters and formulations necessary to synthesize K-PSS geopolymers from commercial kaolin clay, and from two volcanic tuffs. This was done through laboratory experiments performed on ring mills, by posing an upper limit to the grinding ratio used. Although a value of 120 was considered the best compromise to maximize the production, also a value of 250 was tested. The results obtained with mechano-chemically activated kaolin clay are described in Sect. 18.4.1, whereas those obtained with mechano-chemically activated tuffs or by suitable combinations of activated materials are reported in Sect. 18.4.2.

4.1 Geopolymers from Activated Kaolin Clays

After a detailed chemical, mineralogical and structural characterization of the kaolin clay used as test material, aliquots were grinded at increasing times, at rotation speeds of 900 and 1,500 r.p.m. Products obtained were then analysed with the same techniques, to follow the structural changes induced by the mechano-chemical process. The grinding time was increased until very little structural changes were detected in the grinded material. The same protocol was followed in the thermal treatment. In both cases, materials collected until a steady state was reached were checked for their ability to remove Ca(OH)2 (portlandite) from alkaline solutions over a time higher than 28 days, according to the pozzolanic test described in [7, 17]. This allowed to get indications on their reactivity in alkaline solutions. For each of the materials showing a good pozzolanic activity, 3 different formulations were used to obtain K-PSS geopolymers with a Si/Al = 2. The paste obtained from the alkaline reaction was poured in a plastic mould, to get products with a cylindrical shape, whose composition, structure and mechanical and thermal properties were checked after 28 days, when more than 90% of the material was polymerized [7].

A kaolin clay Argical-BS4 from AGS-Mineraux, with a Si/Al = 0.98, and a SSA = 18 m2g−1 was used in these investigations. Information on the oxide composition and physical features can be found in [12]. Grinding was performed on ring mills from Sepor Inc. (Bleuler rotary mill) and Herzog (HSM vibration disk mill), both equipped with steel jars of 200 mL, and a mass M of 3 kg. Solid state NMR spectra of the raw and grinded materials were recorded on a Bruker ASX 200 spectrometer at a spinning rate of 12 kHz, and data processed to assess the relative contents of Al(IV), Al(V) and Al(VI) in the sample. XRF data were collected on a Philips PW 1480 WDS, while XRD diffraction spectra were collected on a Bruker D8 X-ray equipped with a Cu source. FTIR-AR spectra were collected on a Thermo Scientific Nicolet iS10 FTIR-AR equipped with a diamond window. TG determinations were all performed on a SDT Q600 apparatus from TA Instruments.

Figure 18.1 shows the XRD, FTIR-AR, NMR and TGA profiles of the kaolin clay used as test material in our investigations, together with indication of the bands of KA and the other minerals present in it. The thermal conversion of KA into MKA was followed from 300 °C up to 850 °C, while the mechano-chemical one was followed from 10 min to 1 h of grinding time, using a grinding ratio of 120 and a rotation speed of 1,500 r.p.m. With the thermal treatment, MKA started to form at 550 °C, but only at 650 °C a steady state was reached above which the populations of Al(V), Al(IV) and Al(VI) did not change appreciably [7]. With the mechano-chemical treatment, a steady state was achieved in 30 min.

XRD, FTIR-AR, solid state NMR and TG profiles of the clay Argical-BS4 used in this study to produce MKA by thermal and mechano-chemical treatment. Symbols are used to indicate the bands generated by different minerals in kaolin clay. Filled diamond = Kaolinite, empty circle = Illite, empty triangle = Gibbsite, empty square = Quartz

Figures 18.2 and 18.3 show the spectral profiles recorded when treated BS-4 reached a steady state, in which a complete amorphization of KA was observed. In both cases, the amorphization was indicated by the disappearance of the KA reflections and bands generated in the XRD and FT-IR spectra, and by the broadening of the Si band in the NMR spectra. The unambiguous formation of MKA was indicated by the presence of the Al(IV) and Al(V) bands in the 27Al MAS NMR spectra. Since in both cases, only 73–75% of the original Al(VI) was converted in the other bands, the Al(VI) band still remained the most intense in MKA obtained with the independent processes, in evident contrast with the rule theorized by Davidovits [7]. The intensity of the other Al bands were, instead, quite different in the MKAs obtained from the two processes. While the Al(IV) band accounted for 12.6% of total Al in thermally treated BS-4, a value of 24.5% was measured in mechano-chemically treated BS-4. This effect, never detected before, indicated that some structural differences existed between the MKAs obtained with the two processes.

XRD, FTIR-AR, 27Al, 1H and 29Si MAS NMR, and TG profiles of MKA produced by mechano-chemical treatment of the same kaolin clay of Fig. 18.2. Qz = quartz

Consistently with data reported in the literature [9], substantial differences in the water content were observed in the MKAs obtained with the two processes. While few percent losses were measured by TG determinations on thermally treated BS-4, more than 25% weight losses were recorded on the mechano-chemically treated material, indicating that dehydrolixylated water released from KA remained inside the MKA structure. Differences in the water content are clearly visible in the FTIR-AR spectrum of Fig. 18.3, where a series of intense bands between 3,000 and 4,000 cm−1, similar to those produced by zeolitic water in aluminosilicate rocks, were detected. These data are consistent with the 1H MAS NMR spectrum of Fig. 18.3, where intense sidebands, very small in thermally treated BS-4, were observed around the main one.

Profiles of Figs. 18.2 and 18.3 were shown here because they refer to the most reactive MKAs as measured by the pozzolanic test, and by the alkaline reaction leading to the formation of K-PSS geopolymers. Some differences in reactivity existed, however, between the material reported in Fig. 18.2 (from now on indicated as BS-4 TT) and Fig. 18.3 (from now on indicated as BS-4 MT), because aluminium in BS-4 MT was 15% more reactive than that present in BS-4 TT. While 10 g of BS-4 MT needed to be mixed with 14.48 g of K-Sil and 2.39 g of KOH to get the K-PSS geopolymer, only 8.6 g of K-Sil and 2.57 g of KOH were required for the same amount of BS-4 TT. The fluid paste obtained by mixing the reagents for 10 min was cast in a plastic mould, and products analysed after 28 days.

XRD, FTIR-AR and 27Al MAS NMR spectral profiles reported in Fig. 18.4 confirmed that all materials obtained consisted of randomly oriented nano-crystals, characterized by the typical Al(IV) coordination of PSS geopolymers [7].

27Al and 1H MAS NMR profiles of K-PSS geopolymers synthesized from BS-4 MT and BS-4 TT. The formation of a K-PSS geopolymer made of randomly oriented nano-crystals with Al in coordination 4 is evident in both cases. Also evident is the different content of H present in the material as free or adsorbed water

XRF and XPS determinations indicated also that the Si/Al ratio was between 1.9 and 2, and K+ was definitely the compensatory cation. As indicated by the 1H NMR spectra, differences in the water content existed between the two K-PSS geopolymers, and they were confirmed by TG determinations. Results obtained with mercury intrusion porosimetry, performed on a Thermo Finnigan 240 instrument, indicated that the geopolymer formed from BS-4 TT was characterized by an accessible porosity of 8–9% and a total pore volume of 50–52 mm3g−1, whereas the one obtained from BS-4 MT showed an accessible porosity of 25% and a total pore volume of 180–190 mm3g−1. This was explained by the faster reactivity of BS-4 MT, producing clusters of reacting material enclosing water that formed pores when water was released as vapour during the exothermal polymerization step. Differences in porosity explained why geopolymers obtained from BS-4 MT showed a lower UCS value after 28 days (46.5 ± 4 MPa), than those obtained from BS-4 TT (UCS = 55.7 ± 9 MPa). Also the values of the flexural strength of the geopolymers obtained from BS-4 TT (9.5 MPa +1.2) were better than those obtained from BS-4 MT (5.5 ± 0.4).

Since the UCS of all geopolymers fell well within the ranges of commercial clinker cements, their thermal properties were determined using a hot stage microscopy MISURA M3M1600/80/2 from Andersen Lt. It was found that the melting temperatures of K-PSS from BS-4 MT and BS-4 TT were comparable, as all ranged between 1,575 and 1,595 °C, although the sintering process of K-PSS from BS-4 MT started 150 °C earlier than that of BS-4 TT (1,205 °C), indicating a larger reduction in volume due to the different porosity and bulk density of the two products.

The fact that the thermal stability of K-PSS geopolymers obtained from BS-4 MT was close to the highest ever obtained with these geopolymers [7], confirmed the suitability of mechano-chemically formed MKAs to make hard geopolymeric cements with excellent thermal properties.

4.2 Geopolymers from Activated Tuffs and Activated Rock Mixtures

A protocol analogous to that described in Sect. 18.4.1 was followed with tuffs, with the only difference was that no thermal treatments were made on them, and all materials grinded were used to synthesize K-PSS geopolymers. A lithified tuff cemented by zeolites (TRSN) with a Si/Al of 2.45, and a SSA = 5 m2g−1, and a vitric tuff cemented by glass (PTV), with a Si/Al = 3.3 and a SSA of 1.75 m2g−1 were selected as test materials. Details on their origin, petrographic features, and practical applications can be found in [18], together with the average oxide composition and other features, including the spectroscopic ones.

Figure 18.5 highlights well the differences between the two tuffs. The lithified nature of TRSN is well visible from the intense XRD reflections generated by the cementing zeolites chabazite, and phillipsite, accounting for 56–58% and 12–14%, respectively, of the whole sample. Their presence explains the high thermal losses of zeolitic water measured by TG determinations, and the signals of the Si(nAl) pentads generated in the 29Si NMR spectrum. TRSN is a porous and soft material (UCS = 25–30 MPa) with an average pore radius of 2.74 µm, an open porosity of ca. 40%, and an apparent density of 1.97 g cm−3. Thanks to the high zeolite content, it displays a rather good pozzolanic activity [17].

Distinctive features of the welded tuff (PTV) and lithified (TRSN) as recorded by XRD, solid state NMR and TG determinations. Different symbols are used to indicate the minerals present in them. Filled diamond = Biotite, filled triangle = Chabazite, filled circle = Phillipsite, empty diamond = K-felspar Sanidine, empty circle = Plagioclase Bitownite and Anorthtite, empty triangle = Clynopyroxene Augite

The vitric nature of PTV was indicated by the fact that cementing glass accounted for 60% of the whole material, whereas minerals for no more than approx. 35%. The glassy nature of the cementing matrix is well visible from the broad bands generated in the 27Al and 29Si MAS NMR spectra. PTV is a quite hard material (UCS = 40–60 MPa) with an average pore radius of 0.89 µm, an open porosity of 14.4%, and an apparent density is 2.7 g cm−3.

Figure 18.6 shows the loss of crystallinity of the main minerals present in TRSN and PTV as a function of the grinding time. To better follow the kinetic of crystal transformations they were grinded in the ring mill at a lower rotation speed and at a higher grinding ratio than those used in the experiments reported in Sect. 18.4.1.

Amorphization rate of minerals in TRSN and PTV as function of the grinding time. Different symbols are used to indicate the trends followed by the various minerals. Empty circle = zeolite Chabasite (CHA), solid diamond = zeolite Phillipsite (PHI), solid square = K-feldspar Sanidine (San), solid circle, plagioclase Bitownite (Bitow), empty triangle = plagioclase Anorthite, solid triangle = mica Biotite (Biot)

The results in Fig. 18.6 show that the amorphization of minerals proceeded to a different extent as a function of the grinding time, highlighting the role played by the mineral hardness in determining their amorphization rates. The two zeolites present in the TRSN were softer than sanidine, as they were amorphized faster than this mineral, which was still 80% in the crystal phase after 18 min of grinding. Also in PTV, sanidine resulted the hardest mineral, but it was amorphized by more than 45% in 16 min due to the similar hardness of plagioclases anorthite and bitwonite, quite abundant in PTV. In both tuffs, micaceous biotite was the fast mineral to be amorphized, due to its phyllosilicate structure. The partial amorphization of minerals was confirmed by solid state NMR and FTIR-AR.

Tuffs processed at a grinding ratio of 120 and 900 r.p.m. were used for making K-PSS geopolymers, because it was found that no substantial increase in the pozzolanic activity occurred on TRSN grinded above 6 min, and on PTV grinded above 12 min. Various formulations were tested with untreated, and mechano-chemically treated tuffs.

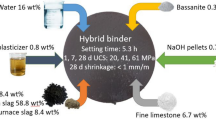

The only geopolymeric product worth to mention was a K-disiloxo-sialate (K-DSS) geopolymer with a Si/Al ratio of 3, obtained from TRSN grinded for 6 min. It showed an UCS of 26.8 ±2.6 MPa, a flexural strength 6.80 ± 0.10 MPa, a density of 1.51 ± 0.05 g cm−3, and a melting temperature of 1,520 °C. The good thermal stability of this product, but also of the weaker obtained with PTV, suggested that both activated materials could be added to BS-4 MT to make blended K-PSS geopolymeric cements. Using different combinations of the grinded materials with BS-4 MT, it was found that up to 40% of activated tuffs could have been used to make K-PSS geopolymers.

Table 18.1 compares the thermal and mechanical properties of K-PSS geopolymers obtained by using BS-4 TT, BS-4 MT and those of the blended ones obtained by mixing 60% of BS-4 MT with 40% of mechano-chemically activated TSN (TRSN-MT) and PTV (PT-MT), both grinded for 6 min. By considering the lower price of tuffs with respect to BS-4, and the short grinding time required for the activation of TRSN (that can be reduced to 3–4 min at a rotation speed of 1,500 r.p.m.) blended geopolymers made with this activated tuff were particularly cost effective with respect to those obtained from BS-4 MT and BS-4 TT.

5 Prototype Milling System for the Mechano-Chemical Processing of Rocks at a Small Industrial Scale

Results presented in Sect. 18.4 suggested that it was possible to develop a prototype system for a small scale production of mechano-chemically activated rocks for geopolymer production, but also for other applications, such as zeolite production. To work in an industrial environment, the prototype was designed in such a way that some operations, such as the charge and discharge of material from the mill or the reduction of the size of the raw material, could have been performed in an automated way. Particular attention was paid to the comminution of the raw material down to the size (200–100 μm) that was the most suitable for mechano-chemical activation. The possibility to directly treat quarried materials in the mill would have reduced the time and costs of the whole process, by eliminating the use of a dedicated mill for the comminution of the sample, that require a quite long time to reduce the size of rocks down to a sandy fraction, due the low speed at which it is operated.

The prototype was built using a continuous ring mill Model ESSA by Labtech that was specifically modified for semi-continuous operations. Since the mass of the moving bodies was 15 kg, and could rotate at same maximum speed (1,500 r.p.m.) reached in laboratory experiments, the maximum energy transferred to particles was 4 times higher. This allowed treating more material in a shorter time. Although limited to 30 kg h−1, the maximum amount of material produced by this prototype was sufficient to test the system in a small industrial facility in which mechano-chemical treatment was needed to make products of technological interest from wastes and rocks.

As indicated in Fig. 18.7, the prototype consisted of two jars set in series. The top jar, which is fed with the raw material by a hopper, contains a rotating disk of 20 kg, named Flying Saucer, that enables a fine grinding the raw material to get only a sandy fraction (D50 ≈ 100 μm) out of it. From the top jar, the sandy fraction falls in a second jar equipped with 2 rings and 1 cylinder as moving bodies, where the material is subjected to mechano-chemical processing. The bottom of the second jar is equipped with a sieve with a defined mesh size range, so that the grinded material can be discharged outside the mill by gravity.

The system was modified to maintain the powder inside the second jar for the time necessary to activate the material. This was done by keeping the top jar under depression to prevent the discharge of material from the second jar. Only when the grinding time necessary to activate the material was reached, the depression was removed and the activated material discharged and utilized. An electric valve was used to maintain the depression inside the system. With these modifications, the ring mill basically worked as a fluidized mechano-chemical reactor, able to optimize the whole mechano-chemical processing of the material.

6 Prototype Testing and Design of a Milling System for a Full Scale Industrial Production

This section reports the results obtained by testing the prototype system in a representative industrial environment (Sect. 18.6.1) and how these results were exploited to design a milling system for large industrial applications (Sect. 18.6.2).

6.1 Prototype Testing

The prototype system described in Sect. 18.5 was tested in a demonstration plant for the production of zeolites from industrial wastes built by the Sicily region in Melilli. Figure 18.8 shows a schematic diagram of the various processes used by the plant to produce zeolites, and the position where the prototype for the mechano-chemical activation of wastes was located. When exhausted catalysts from the cracking of crude oil were treated, the mechano-chemical unit was placed after the unit separating the iron-containing fraction of wastes.

When the proper degree of activation was reached, the material was transferred in a closed reactor kept at 90 °C that was filled with NaOH 1 M, from which zeolites were formed by hydrothermal reaction. Using an M/m ratio of 400, the mill was able to activate these wastes in 2 min. The degree of activation was such that grinded products reacted so quickly with alkaline solutions to form zeolites in less than 10 h. This was a relevant result, because more than one month was necessary to produce the same amounts of zeolite from the untreated wastes. Since the zeolite formed from these wastes was the same present in volcanic tuffs, the product showed a good pozzolanic activity, and could have been used for the production of pozzolanic cements and blended Si–Al geopolymers.

In the Melilli plant, the prototype was able to treat 144 kg of industrial wastes per day, with no substantial problems during 10 months of testing. The high versatility of the milling system was demonstrated by the fact that for a short period it was fed with volcanic ashes produced by the Etna volcano, that were also converted into zeolites different from those obtained from industrial wastes. In the treatment of volcanic ashes, the presence of the Flying Saucer shown in Fig. 18.7 resulted particularly useful to reduce the time and cost of the final products, because of the wide and different size range of the raw material used.

Preliminary results showed that 20 min of grinding were needed to make the volcanic ashes sufficiently reactive for the synthesis of zeolites. Due to the high content of hard minerals (plagioclases) in the ashes, a long activation time was needed to reach the degree of amorphization necessary to produce zeolites out of them.

6.2 Design of an Industrial Mill for Mechano-Chemical Treatment of Rocks

Although the results reported in Sect. 18.6.1 showed the ability of the mechano-chemical system to work in an industrial plant, the amount of treated material was still too low for a full scale industrial production, where 5 tons of material per day, corresponding to 420 kg h−1 for 12 h, can be regarded as an acceptable target.

To achieve this goal, a further research was made to improve the geometry of the milling system. It was aimed at drastically reducing the heavy vibration problems posed by ring mills, where moving bodies are forced to rotate in an eccentric mode. The geometry shown in Fig. 18.9 was selected, because it ensures the same collision and friction forces than a ring mill, but it does not induce heavy vibrations in the horizontal and vertical plane. It is composed of a jar with 4 grinding masses connected to the shaft of an electrical motor through mechanical arms, letting the mass free to move toward the cylindrical walls by centrifugal forces. In this way the same shearing and friction forces acting in a ring mill can be simultaneously applied to the crystal grains.

To calculate the dimensions and operational parameters required by the mill, a model was used to estimate the specific energy transferred by the system to the grinded material. The time needed to produce 5 tons per day of MKA from BS-4 was thus derived using the data obtained from laboratory experiments. This was necessary, because present models are unable to predict with sufficient accuracy the impact that co-grinding effects, arising the simultaneous presence of different minerals in the material, have in affecting the enthalpy of the phase transitions occurring on each of them.

The power (P in Watt) required to move the grinding bodies in this type of mill was calculated with the model developed by Founti et al. [19] reported in Eq. (18.2), where d is the jar diameter in m, ω is the rotation speed in Hz, µ is the friction coefficient and Q is the centrifugal force in N.

In the configuration of Fig. 18.8, Q is equal to π3/3600 · Mω2a, where a is the distance in m between the centre of the mill and the wall of the jar, and M the mass of the moving bodies in kg. Calculations were made by considering a mill with 4 jars, one on top of the other, having a diameter of 1.2 m and a volume of 340 L each, where only 2 grinding bodies of 1,161 kg were present. From the data listed in Table 18.2, the system can produce 5 tons of MKA per day from BS-4, because is able to fully convert 14 kg of KA into MKA in 2 min. According to the engineers of a mechanical company, this geometry, if properly built, can safely work up to a rotating speed of 2,000 r.p.m., thus further reducing the grinding time.

Based on the data reported in Table 18.2, 7,000 kW h−1 t−1 were estimated to produce 5 tons of MKA per day, by considering the time required for the discharge and charge of the mill. These figures strongly differ from those provided by some authors, according to which only 1,000 kW h−1 t−1 are required to convert KA in kaolin clays into MKA. Since no industrial mills for the production of MKA are presently in operation, it is not clear how these estimates were made. The estimate of the energy necessary to produce MKA by thermal processing appear more realistic, because a value of 2,000 kW h−1 t−1, including that required for the comminution of the raw material, was given. Although these figures can be affected by more than 40% uncertainty depending upon the type of kiln and fuel used, still the mechano-chemical processing appears more energy demanding.

Only if the total costs are analysed, the mechano-chemical treatment of rocks becomes competitive with the thermal one. The investment and operating costs of a plant for the grinding and thermal processing of kaolin clays are in fact much higher than those of mechanical processing, if the expenses for the control of combustion, and those for the monitoring and abatement of atmospheric pollutants in the emission, primarily NOx, VOC, CO and particulate matter, are also considered. These costs can be quite high also because rotary kilns for thermal treatment of minerals in rocks must be maintained into a continuous operation, even when the product demand is low, and the price of fuel is high. This does not happen with the mechano-chemical treatment, where the production can be better tailored to the market demand, as the mill can be turned off when the demand is low, and operated when the demand is high.

If the composition of the raw material changes, a large amount of material is consumed with the thermal treatment before the optimal conditions to get a new MKA with comparable reactivity is obtained. These limitations do not apply to the mechano-chemical treatment, because the system can be more easily fine-tuned as a function of the material to be treated, as it was shown by the tests performed in Melilli plant, where in 1–2 h it was possible to switch from industrial wastes to Etna ashes.

The fact that a mechano-chemical mill with the same size of that described in Table 18.2 can be transported near the extraction plant, and powered with electricity produced through renewable resources, can further reduce the costs of transport, which can be also high in the case of thermal treatment, and contribute to the total CO2 emission.

7 Conclusions and Future Research

The results of this research highlighted some of the capabilities afforded by the use of the mechano-chemical treatment of different materials for making pure and blended K-PSS geopolymeric cements with good mechanical properties and an extraordinary thermal resistance. In particular, the possibility to replace 40% of kaolin clay with mechano-chemically activated tuffs can reduce the cost of the cementing product by more than 50%, due to the lower price and much smaller energy required for activating lithified tuffs with respect to any kaolin clay. The testing of the small prototype has emphasized the capability and reliability of the mechano-chemical treatment to work unattended in an industrial facility, where the possibility to rapidly switch from one raw material to another to produce different zeolites was also demonstrated.

In spite of the advantages offered by geopolymeric cements, the idea to produce them at an industrial scale has not raised so much enthusiasm in the Italian cement industry, probably due to the fact that the persistent crisis in the building industry has so decreased the profits, that funds available for research and development are not sufficient to build a demonstration plant for new types of cements. The mechano-chemical processing of materials has raised, instead, great interest, although the lack of grinding systems operating at a large industrial scale has posed some limits to it.

From a scientific point of view, this is the first study in which mechano-chemically treated kaolin clays and volcanic tuffs were mixed together to make low price geopolymeric cements with high mechanical and thermal properties. From a theoretical point of view, the use of solid state NMR in combination with other techniques has allowed to identify structural differences between MKA obtained by thermal and mechano-chemical treatment that can explain the different reactivity of the two materials in alkaline media. Our result show also that not necessarily the most reactive MKA has a structure in which the Al(V) population is always dominant, and, consequently, the rule proposed by Davidovits [7] cannot be considered a universal one. Since the chemistry of geopolymers strongly relies on this rule, our results open a new perspective on the possible relations between the reactivity and structure of MKA, suggesting that, in spite of the outstanding progress made in recent years with different modelling approaches, the structure of MKA is still poorly understood, and certainly deserves further investigations to be clarified.

From the results obtained in our study, the mechano-chemical activation of industrial wastes from which various products can be obtained is certainly a promising field for future investigations. In particular, the co-grinding of different raw materials to get new and more reactive phases is a highly promising. While the co-grinding of clinker and different SCM can lead to new clinker-based cements, the co-grinding of kaolin clays and tuffs can lead to MKA structures better suited for the synthesis of Si–Al geopolymers.

References

Roadmap to a Resource Efficient Europe Documents (2011) CSST/2011/1463. COM/2011/571/FINAL. http://www.europarl.europa.eu/meetdocs/2009_2014/documents/com/com_com(2011)0571_/com_com(2011)0571_en.pdf

Olivier JG, Janssens-Maenhout G, Muntean M, Peters JHAW (2016) Trends in global CO2 emissions—2016. JRC report, PBL publication number 2315. http://edgar.jrc.ec.europa.eu/news_docs/jrc-2016-trends-in-global-co2-emissions-2016-report-103425.pdf

European Environment Agency (2015) Trends and projections in the EU ETS in 2015. EEA technical report no 14/2015. ISSN 1725–2237. https://www.eea.europa.eu/publications/trends-and-projections-eu-ets-2015

Cembureau, Cements for a low carbon Europe (2012) Report D/2012/5457/ November 2012. https://cembureau.eu/media/1501/cembureau_cementslowcarboneurope.pdf

Associazione Italiana Tecnico Economica del Cemento (2015) Relazione annuale 2015. https://www.aitecweb.com/Portals/0/pub/Repository/Area%20Economica/Pubblicazioni%20AITEC/Relazione_Annuale_2015.pdf

De’ Gennaro M, Langella A (1996) Italian zeolitized rocks of technological interest. Miner Deposita 31(6):452–472

Davidovits J (2011) Geopolymer chemistry & applications. Institute Géopolymere, S. Quentin, France

Takahashi H (1959) Effects of dry grinding on kaoilin minerals. Bull Chem Soc Jpn 32:235–263

Sugiyama K, Filio JM, Sajto F, Waseda Y (1994) Structural change of kaolinite and pyrophyllite induced by dry grinding. Mineral J 17:28–41

Gualtieri A, Bellotto M (1998) Modelling the structure of the metastable phases in the reaction sequence kaolinite-mullite by X-ray scattering experiments. Phys Chem Miner 25(6):442–452

He HP, Guo JG, Zhu JX, Hu C (2003) 29Si and 27Al MAS NMR study of the thermal transformations of kaolinite from North China. Clay Miner 38(4):551–559

Fabbri B, Gualtieri S, Leonardi C (2013) Modifications induced by the thermal treatment of kaolin and determination of reactivity of metakaolin. Appl Clay Sci 73:2–10

Temuujin J, MacKenzie KJD, Schmucker M, Schneider H, McManus J, Wimperis S (2000) Phase evolution in mechanically treated mixtures of kaolinite and alumina hydrates (gibbsite and boehmite). J Eur Ceram Soc 20:413–421

Bellotto M, Gualtieri A, Artioli G, Clark SM (1995) Kinetic study of the kaolinite-mullite reaction sequence. Part I: kaolinite dehydroxylation. Phys Chem Miner 22(4):207–214

Cundy CS, Cox PA (2005) The hydrothermal synthesis of zeolites: precursors, intermediates and reaction mechanism. Microp Mesop Mater 82(1–2):1–78

Prokof’ev VY, Gordina NE, Efremov AM (2013) Synthesis of type A zeolite from mechano activated metakaolin mixtures. J Mater Sci 48(18):6276–6285

Mertens G, Snellings R, Van Balen K, Bicer-Simsir B, Verlooy P, Elsen J (2009) Pozzolanic reactions of common natural zeolites with lime and parameters affecting their reactivity. Cem Concr Res 39(3):233–240

Ciccioli P, Plescia P, Capitani D (2010) 1H, 29Si, and 27Al MAS NMR as a tool to characterize volcanic tuffs and assess their suitability for industrial applications. J Phys Chem C 114(20):9328–9343

Founti M, Zannis G, Makris P (2008) Power aspects of a horizontal ring mill pulverizer under continuous comminution of olivine. Int J Min Process 85(4):85–92

Terkaj W, Tolio T (2019) The Italian flagship project: factories of the future. In: Tolio T, Copani G, Terkaj W (eds) Factories of the future. Springer

Acknowledgements

This work has been funded by the Italian Ministry of Education, Universities and Research (MIUR) under the Flagship Project “Factories of the Future—Italy” (Progetto Bandiera “La Fabbrica del Futuro”) [20], Sottoprogetto 1, research projects “Mechano-chemistry: an innovative process in the industrial production of poly-sialate and poly-silanoxosialate geopolymeric binders used in building construction” (MECAGEOPOLY). The technical support of Laura Lilla and Emanuela Tempesta is also acknowledged. We would like to thank the chemists of Colacem S.p.A. (Gubbio, Italy) and the engineers of Officina Meccanica Molinari S.r.l. (Bergamo, Italy) for the helpful discussions, and the Sicily Region which allowed us to test the prototype in the demonstration plant of Melilli (Siracusa, Italy).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2019 The Author(s)

About this chapter

Cite this chapter

Ciccioli, P. et al. (2019). Mechano-Chemistry of Rock Materials for the Industrial Production of New Geopolymeric Cements. In: Tolio, T., Copani, G., Terkaj, W. (eds) Factories of the Future. Springer, Cham. https://doi.org/10.1007/978-3-319-94358-9_18

Download citation

DOI: https://doi.org/10.1007/978-3-319-94358-9_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-94357-2

Online ISBN: 978-3-319-94358-9

eBook Packages: EngineeringEngineering (R0)