Abstract

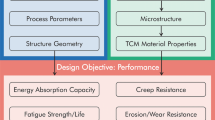

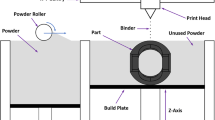

Metal additive manufacturing (AM) is an innovative and enabling manufacturing technology that is also pervasive/cross cutting in terms of system applications , dual-use potential and interest from multiple agencies. AM technologies build near-net/net shape components, one layer at a time, using digital data from 3D CAD models. In addition, AM has the potential to enable novel product designs that could not be fabricated using conventional subtractive processes. The goal of this Metals Affordability Initiative (MAI) project (HON-9 Agreement Order Number FA8650-14-2-5204) is to create a cross-functional team focused on developing the necessary Integrated Computational Materials Engineering (ICME) based framework, knowledge and supporting models to enable powder bed AM production of nickel-based superalloy aerospace and space components. An Activity Integrated Project Team (AIPT) comprising of Honeywell Aerospace (Lead), Aerojet Rocketdyne, ATI Powder Metals, Carpenter Powder Products, Lockheed Martin, Northrop Grumman, Rolls-Royce Corporation, Arconic Inc. along with Applied Optimization and QuesTek as major subcontractors was formed. The AIPT successfully completed the concept feasibility demonstration for additively manufactured Alloy 230 components. A focused series of design of experiments (DOE ) related to machine parameters and post processing operations were designed and implemented within Concept Laser Cusing M2 machine. The collected empirical data was used to optimize process parameters, calibrate ICME models, and improve tool maturity level (TML) of the ICME framework for AM of Ni superalloy components. A preliminary business case was developed for parts from Honeywell Aerospace, Aerojet Rocketdyne, Rolls-Royce Corporation, Northrup Grumman and Lockheed Martin.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Peralta AD, Enright M, Megahed M, Gong J, Roybal M, Craig J (2016) Towards rapid qualification of powder-bed laser additively manufactured parts. Int Mat Manuf Innov 1–23. https://doi.org/10.1186/s40192-016-0052-5

Qui C et al (2015) On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater 96:72–29

Pupo Y, Monroy K, Ciurana J (2015) Influence of process parameters on surface quality of CoCrMo produced by selective laser melting. Int J Adv Manuf Technol 80:985–995

DuPont J Fundamentals of weld solidification. Weld Fund Process 6:96–114

Jou H-J, Voorhees P, Olson GB (2004) Computer simulations for the prediction of microstructure/property variation in aeroturbine disks. In: Green KA, Pollock TM, Harada H, Howson TE, Reed RC, Schirra JJ, Walston S (eds) Superalloys 2004 (TMS), pp 877–886

Gong J, Snyder D, Kozmel T, Kern C, Saal JE, Berglund I, Sebastian J, Olson G (2017) ICME design of a castable, creep-resistant, single-crystal turbine alloy. JOM 69:880–885

Kuehmann CJ, Olson GB (2009) Computational materials design and engineering. Mater Sci Technol 25:472–478

Whittenberger JD (1994) 77–1200 K tensile properties of several wrought superalloys after long-term 1093 K heat treatment in air and vacuum. J Mater Eng Perform 3:91–103

Kozar RW, Suzuki A, Milligan WW, Schirra JJ, Savage MF, Pollock TM (2009) Strengthening mechanisms in polycrystalline multimodal nickel-base superalloys. Metall Mater Trans A 40A:1588–1603

Duva JM (1984) A self-consistent analysis of the stiffening effect of rigid inclusions on a power-law material. J Eng Mater Technol 106:317–321

Wang J-S, Mulholland MD, Olson GB, Seidman DN (2013) Prediction of the yield strength of a secondary-hardening steel. Acta Mater 61:4939–4952

Foster BK, Reutzel EW, Nassar AR, Hall BT, Brown SW, Dickman CJ (2015) Optical, layerwise monitoring of powder bed fusion. In: 26th international solid freeform fabrication symposium, Austin, TX, pp 295–307

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Sundarraj, S. et al. (2018). ICME Based Additive Manufacturing of Alloy 230 Components. In: Ott, E., et al. Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-89480-5_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-89480-5_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-89479-9

Online ISBN: 978-3-319-89480-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)