Abstract

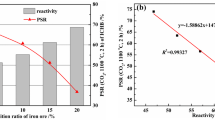

To reduce coke consumption in blast furnace ironmaking, this study proposed a new method of applying iron-coke briquette prepared using hematite powder and pulverized coal to protect coke in BF iron making. Results showed that, with a ratio of hematite to coal of 2.0, the iron-coke briquette could obtain a satisfying compressive strength of more than 1500 N both before gasification and after being gasified by CO2 for 1 h. The activation energy of the iron-coke briquette was 93–135 kJ/mol, which is lower than the coke and therefore could protect the coke in BF. The agglomeration and stratification of iron particles occur in the course of iron-coke briquette gasification and is beneficial to the improvement of the iron-coke briquette strength.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Guo YL, Hu JG, Zhou WT (2014) Effect of coke quality on blast furnace ironmaking. Shanghai Metal 36(3):51–55

Anyashiki T, Fukada K, Fujimoto H (2009) Development of carbon iron composite process. JFE Tech Rep 13:1–6

Yu Y, Wang L, Li JS (2008) Present state and development trend of BF pulverized coal injection technology at home and abroad. Henan Metall 16(5):1–3

Higuchi K, Nomura S, Kunitomo K (2011) Enhancement of low-temperature gasification and reduction by using iron coke in laboratory scale tests. ISIJ Int 98(10):517–525

Yamamoto T, Sato T, Fujimoto H (2011) Reaction behavior of ferro coke and its evaluation in blast furnace. Tetsu-to-Hagane 97(10):501–509

Acknowledgements

The authors wish to thank State Key Laboratory of Advanced Metallurgy of University of Science and Technology Beijing (USTB) for its financial supports.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Yan, P., Tang, H. (2018). Preparation and Characterization of Iron-Coke Briquette. In: Hwang, JY., et al. 9th International Symposium on High-Temperature Metallurgical Processing. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72138-5_73

Download citation

DOI: https://doi.org/10.1007/978-3-319-72138-5_73

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72137-8

Online ISBN: 978-3-319-72138-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)