Abstract

Carbon fiber-reinforced polyurethane composites were received by means of technique, which includes modification of polyurethane–carbon fiber interface. The modification was done by carbon nanotube grafting onto a surface of the fiber. A sophisticated grafting technique allowed to avoid almost inevitable grafting-induced deterioration of the fiber properties. The technique implies the introduction of an intermediate protective aluminum oxide layer. The measurement of interfacial shear strength (IFSS) was used for estimation of polymer–fiber interface properties. It was shown that IFSS doubled due to nanotube grafting. The enhancement of both thermal conductivity and mechanical properties including delamination resistance was registered for composites with the modified interface, which allows to state that the resulting materials can be considered as novel flexible composites.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

The carbon fiber-based (CF-based) composites have recently become a choice for the most responsible applications. Despite growing demand for such composites, many application areas are still closed for the CF-based composites due to delamination, which makes all the composite properties poorer because the load in the composites is transferred from the matrix to the fiber through the shear stress. Delamination, in turn, is determined by weak CF-to-matrix binding. This weak CF-to-matrix binding maybe improved and a better interfacial shear strength (IFSS) maybe reached through the control of the fiber–matrix interface [1, 2].

Earlier attempts to improve the situation by carbon nanotube (CNT) grafting onto the CF surface were reported in literature [1, 3, 4]. It is obvious that grafting would increase the IFSS due to CNT-assisted increase of active surface area, local stiffening and mechanical interlocking at the fiber-matrix border. However, a drastic drop in the CF tensile strength was reported in [3, 5, 6] although some authors such as [7] showed more optimistic results. The negative results are most probably induced by the CF surface erosion due to interaction with catalyst particles. Such erosion can be prevented by the introduction of an interlayer at the surface of CF as suggested in [5].

The purpose of this work was to show that a flexible CF-reinforced composite can be produced if a proper technique is elaborated for CF–polymer interface modification. Polyurethane was suggested as a matrix for the composites due to its resistance to moisture, corrosion, and wear.

Experimental

Polyurethane with value 90 of Shore A hardness was used as a matrix. That polyurethane was based on di(methylthio)toluene diamine and 2,6-toluene diisocyanate (by Smooth-on, Inc.). The so-called mid-grade polyacrylonitrile-derived carbon fibers UKN-M-12k (provided by Argon Ltd., Russia) were used in this work. The fibers were arranged in bundles of 12,000 monofilaments each (specific weight 1.75 g/cm3, average diameter of a filament 7 µm). These fibers can be characterized by Young modulus of 220 GPa, tensile strength of 3.0 GPa, and strain-to-failure of about 1.2%. Both fibers and composites were characterized by scanning electron microscopy (SEM). A tensile testing machine “Instron 5980” was used for the measurement of mechanical properties of both CF (with 100 mN sensitive sensor) and composites (with 1 kN sensitive sensor, ASTM D3039 measurement). Every single value of stiffness or strength was received by averaging at least 20 different measurements.

A modified “microdroplet” test [3] was used for interfacial shear strength (IFSS). It implied single filament pull-out tests, i.e., a monofilament was fixed in grips, then the bottom part was immersed into polyurethane precursor. After polymer curing, the bottom part was carefully cut for obtaining samples where the length of immersed fiber was measured. Usually, this length was about 1–2 mm. The values of IFSS were calculated from a maximum load, a monofilament diameter, and the gauge length of monofilament. 20 specimens were tested for each material. These measurements were also carried out at Instron 5980.

Thermal conductivity of composites was determined in 45–50 °C temperature range through heat capacity [DSC8000 (Perkin Elmer)] and temperature conductivity (NETZSCH LFA 457/2/G MicroFlash analyser).

The fiber tows were precoated by soaking into 5% aluminum hydroxide sol. The formed hydroxide layer was dried at 300 °C and then annealed at 800 °C in Ar atmosphere. The after-annealing thickness of the formed Al2O3 was 70 nm (estimated by SEM). The Al2O3 content was 3.3% weight.

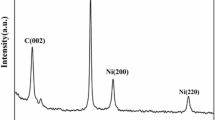

The Al2O3-precoated CF was impregnated with the catalyst precursor [aqueous Fe (II) acetate] solution and then went through CVD process (carbon nanotubes growth). The precursor was decomposed in H2 at 550 °C, which provides formation of Fe nanoparticles at the surface of Al2O3. The atomic ratio of Fe/Al varied 1/20–1/10 along the fiber as determined by EDS spectroscopy.

The CVD process employed the He/H2 mixture (33 mol% of H2) as a carrier gas. Ethanol vapor was introduced into the carrier gas by means of bubbling the gas through absolute ethanol at the temperature of 25 °C. The duration of CVD process was 20 min at the temperature of 700 °C. This temperature value was chosen as an optimal value, which provides high enough CNT yield without any significant deterioration of CF mechanical properties. More details of the grafting can be found elsewhere [7].

The composites were fabricated from polyurethane and modified CF in the following way: putting a CF tow into a plastic tooling; then filling the tooling with polymer precursor; and then rolling and tolling down to the required shape. The CF weight content in the composite was 60%. As a result, a composite sample looked like a flat strip.

Results and Discussion

Modification of CF surface with carbon nanotubes resulted in significant changes in the CF surface morphology and structure. Figure 1 manifests that smooth and featureless surface of pristine fibers (Fig. 1a) becomes grafted with multiple nanotubes (Fig. 1b). The nanotubes have length from 0.1 to 5 µm, and the diameter of CNT varies 5–30 nm.

The grafted fibers did not undergo serious deterioration although some decrease (less than 10%) in tensile strength σ was still observed as shown by single filament tensile tests. Neither elastic modulus E nor failure strain ε showed any strong variations—see Table 1.

The interface shear strength results are shown in Table 2. One can see a slow increase of pulling load due to CF monofilament tightening while pulling from the polymer, then a steady increase of the pulling load because of elongation of the CF monofilament, and, finally, a failure. This is, actually, a classical behavior. Modification of the fiber–polymer interface with carbon nanotubes leads to drastic increase of IFSS by 144%.

The composites were fabricated as elongated strips with carbon fibers aligned inside. SEM of such materials is especially informative if a fracture surface is pictured just after destruction. As a result, one can make conclusions not only on the structure, but also on the destruction mechanism, which becomes obvious after analyzing SEM of fractured surfaces in Fig. 2. It can be seen that pristine fibers slip out of the matrix due to weak adhesion and very easy delamination between monofilaments and polyurethane. The surface of the pristine fibers is smooth and clean after slipping away.

The composites with nanotube-grafted fibers, in contrast, undergo fracture in a very different way. Even after fracture the modified fibers are covered with polymer even after fracture as manifested in Fig. 2b. It means that the load transferability is indeed important. CNT remains on CF surface and penetrate through residual polymer, which improves the resistance to delamination.

The powerful interlocking at the polymer–carbon interface and penetration of CNT into the polymer led to thermal conductivity jump (see Table 2). This jump happens due to better fiber–polymer heat transfer through the improved CNT-enhanced interface. It is also possible that percolation takes place due to long enough CNT, which can span through the sample.

The composite with CNT-grafted fibers manifested lower tensile strength than the pristine CF-based composite; the difference was as small as 14%. This value is very similar to the value of the monofilament strength decrease, so there is a reasonable assumption that better interlocking at the fiber–matrix interface was compensated by lower strength of the fibers proper. It is remarkable that the stiffness increased for composites with modified CF up to 23% as shown in Table 2. The increase of stiffness suggests significant load transfer after fiber modification.

Conclusions

Grafting carbon nanotubes onto carbon fiber surface can be accomplished with preservation of the pristine fiber properties due to the application of an improved grafting technique. Although some loss in tensile strength of modified composites is still observed, it can be improved in the future. It means that composites with promising properties become possible due to modification of the fiber–polymer interface and doubling the IFSS. Both composites stiffness and thermal conductivity show significant enhancement and thus afford new opportunities for future applications. The development of flexible composites with outstanding delamination resistance due to improvement of the interfacial properties of carbon fibers in elastomeric matrices is revealed by this study.

References

Qian H., Bismarck A.-J., Greenhalgh E.S., Kalinka G., Shaffer M.S.: Hierarchical composites reinforced with carbon nanotube grafted fibers: the potential assessed at the single fiber level. Chem. Mater. 20, 1862–1869 (2008)

Zhao, J., Liu, L., Guo, Q., Shi, J., Zhai, G., Song, J., Liu, Z.: Growth of carbon nanotubes on the surface of carbon fiber. Carbon 46, 365–389 (2008)

An, F., Lu, Ch., Li, Y., Guo, J., Lu, X., Lu, H., He, S., Yang, Y.: Preparation and characterization of carbon nanotube-hybridized carbon fiber to reinforce epoxy composite. Mater. Des. 33, 197–203 (2012)

Thostenson E.T., Li W.Z., Wang D.Z., Ren Z.F., Chou T.W.: Carbon nanotube/carbon fiber hybrid multiscale composites. J. Appl. Phys. 91, 6034–6037 (2002)

Urvanov S.A., Alshevskiy Yu.L., Karaeva A.R., Mordkovich V.Z, Chernenko D.N., Beyilina N.Yu.: Carbon fiber modified with carbon nanotubes and fullerenes for fibrous composite application. J. Mater. Sci. Eng. 3, 725–731 (2013)

Zhang, Q., Liu, J., Sager, R., Dai, L., Baur, J.: Hierarchical composites of carbon nanotubes on carbon fiber: influence of growth condition on fiber tensile properties. Compos. Sci. Technol. 69, 594–601 (2009)

De Greef N., Magrez A., L. Couteau E., Locquet J.-P., Forro L., Seo J.W.: Growth of carbon nanotubes on carbon fibers without strength degradation. Phys. Status Solidi B. 249, 2420–2423 (2012)

Acknowledgements

Research is carried out (conducted) with the financial support of the state represented by the Ministry of Education and Science of the Russian Federation. Agreement (contract) no. 14.577.21.0094, October 25, 2014. Unique project Identifier: RFMEFI57714X0094.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

This chapter is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

Copyright information

© 2018 The Author(s)

About this paper

Cite this paper

Karaeva, A.R., Kazennov, N.V., Mordkovich, V.Z., Urvanov, S.A., Zhukova, E.A. (2018). Carbon Fiber-Reinforced Polyurethane Composites with Modified Carbon–Polymer Interface. In: Anisimov, K., et al. Proceedings of the Scientific-Practical Conference "Research and Development - 2016". Springer, Cham. https://doi.org/10.1007/978-3-319-62870-7_44

Download citation

DOI: https://doi.org/10.1007/978-3-319-62870-7_44

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-62869-1

Online ISBN: 978-3-319-62870-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)