Abstract

Unsaturated surface soils with porosities above 50% cover great extensions of areas in Midwest Brazil. Because of their large volumes of voids, these soils undergo great strain under loads. In addition, many of these soils are collapsible, i.e., when the soils are under load and in case of a significant increase in the moisture content or saturation of the soil, the structure collapses, thus producing unacceptable displacement values for the buildings. Because of these characteristics, problems often occur in industrial floors, pavements and other types of slabs on ground and shallow foundations.

To solve this problem, compaction of the topsoil is performed before starting the construction. For this study, the soil characteristics are analyzed using both geotechnical laboratory tests and field tests in order to predict the soil behavior in terms of deformability, resistance and collapsibility.

The study was conducted at the experimental site located at the State University of Campinas - Unicamp, in the municipality of Campinas, State of São Paulo, Brazil. The geotechnical properties of the subsoil were determined by collecting undisturbed samples down to 8 m in depth and deformed samples up to 9 m of depth (impenetrable). Simple recognition surveys were performed: standard penetration test (SPT) and electric static cone penetration test (CPT).

The edometric tests conducted on undisturbed samples with flooding at different levels of stress revealed collapsible characteristics of the soil. With the conduction of tri-axial tests (CU), numerical values were obtained for the angle of friction and the cohesion intercepts for each depth. Paschoalin Filho (2008) verified a significant reduction in these values with soil saturation.

The influence of soil deformability and of the type of load on industrial floors is analyzed. The results indicate huge influence of soil deformability in the case of distributed loads, and a minor influence in case of concentrated loads.

The thickness of the compacted soil layer is very important to the definition of the modulus of subgrade reaction (k) for the studied soil.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Collapsible soils are non-saturated soils with a potentially unstable porous structure. Once under the action of a load, their index of voids is suddenly reduced in case of a certain increase in moisture content. For such, there must be cementation or suction to keep the soil structure stable in its natural condition. However, In case the soil is flooded with water, suction ceases to exist and the cement may dissolve destabilizing the structure of the soil.

Soil collapse may damage buildings and floors due to the magnitude of differential settlements in case of rupture of pipes, flooding, water table increase, among others (Gon 2011).

Excavating the soil down to a certain depth and filling the same material back in a controlled manner is a way to improve the supporting soil of shallow foundations, industrial floors and pavements on collapsible soils by increasing resistance, rigidity and stability against collapse, and reducing both strain and permeability (Ribeiro and Futai 2010).

This improvement can be verified in the soil analyzed in this work by the increased rigidity and resistance obtained via edometric and triaxial tests using compacted and undisturbed samples of soil. The effect of this improvement on the design of industrial floors is analyzed.

The study was conducted at the campus of the State University of Campinas - Unicamp, city of Campinas, State of São Paulo, Brazil. Several researches have already been conducted on the soil of the campus, and laboratory tests were made in non-deformed and deformed samples down to 9-m depth, as well as field tests: SPT with torque check (SPT-T), electric (CPTU) and mechanical (CPT) cone tests with Begeman sleeve, cross-hole test, vertical seismic sounding, and Menard-type pressiometric and dilatometric (DMT) tests (Paschoalin 2008).

1.1 Occurrence of Collapsible Soils in Brazil

Collapsible soils cover approximately 50% of the southwest region of Brazil. Giacheti (1991) presents a map pinpointing collapsible soils with geological/geotechnical characteristics potentially similar to the soil studied in the city of Campinas (Fig. 1). Besides this vast region, Ferreira et al. (2007) present records of collapsible soils in different states of the northeast and north of Brazil: Amazonas, Pará, Tocantins, Piauí, Paraíba, Rio Grande do Norte, Pernambuco and Bahia. Bandeira et al. (2012) also mention occurrence of such collapsible soils in the state of Ceará.

Taking into account the large areas of collapsible soils in Brazil, it is necessary to learn more about the behavior of such soils and take their characteristics into due account when designing shallow foundations, industrial floors and rigid pavements.

1.2 Compaction as Soil Improvement

The most commonly method used worldwide to construct buildings with the use of surface foundations on porous, collapsible ground is to remove the surface layer, compact it and return it to the same place (Ribeiro and Futai 2010).

Souza and Cintra (1994) carried out four circular plate load tests and two tests in continuous footings measuring 0.70 m × 3.02 m, all of which were seated at a depth of 0.70 m. The study was carried out in porous soils in the countryside of the state of São Paulo, in the city of Ilha Solteira. Two of the plate tests were performed with soil in its natural moisture, one of which on a compacted soil layer. Two more plate tests were performed likewise but in flooded soil.

The authors concluded that compaction reduced collapse settlement by 86%. Settlements in other steps of loading were reduced by 50%. The conclusion was that compaction was a cost-effective, efficient and easy to use process to enable use of shallow foundations in this type of soil. After an analysis of the results shown in this research, the observation was that compacted soil increased the bearing capacity of foundations by approximately 100% when compared to the same moisture content. Another conclusion was that compacted soil, when flooded, resisted 36% more than soil in its natural condition.

In the cases mentioned, the soil was compacted down to a “Z” depth equal to the smallest dimension of “B” footing; the width of the compacted regions is the width of “B” footing, with an addition of B/2 on each side, as shown in Fig. 2.

Considering that stresses propagate at depth in a 1:2 distribution, compaction with the width of B plus B/2 on each side causes the added stress to occur only on the compacted soil at depth Z = B and, at this depth, this added stress is only 25% of the stress applied by the footing, thus reducing the collapse of the natural soil due to reduced stress (Cintra and Aoki 2013).

Guimarães and Ferreira (1998) conducted several laboratory tests with compacted samples and also confirmed the efficacy of controlled compaction to improve soils in the state of Pernambuco as to reduction of collapse.

1.3 Study Site

There are two experimental sites at the campus of the State University of Campinas - Unicamp, in the city of Campinas, state of São Paulo, where several researches have been conducted. One is the experimental site of the School of Agricultural Engineering (FEAGRI). The other is the experimental site of the School of Civil Engineering, Architecture and Urbanism (FEC). The distance between the sites is approximately 300 m and both are installed in an area with the same type of soil, so the results can be interpreted as representative of one large region.

The FEC experimental site has a 600-m2 area. Its geodesic coordinates in the WGS84 geodesic system are: latitude −22º49′01″ and longitude −47º03′41″; the experimental site of FEAGRI as a 400-m2 area, with the following coordinates: latitude −22º49′10″ and longitude −47º03′40″. Figure 3 shows the location of the experimental sites at the Unicamp campus. Paschoalin (2008) described part of the researches conducted at the experimental site of FEAGRI until 2008: Peixoto (2001), in which several SPT-T type tests were performed; Fontaine (2004) executed electric cone tests and pressiometer tests; Carvalho et al. (2000) provided geotechnical characteristics obtained by means of several field and laboratory tests; Albuquerque (2001), Nogueira (2004) and Paschoalin (2008) carried out several load tests on piles. Giachetti (1991) and Albuquerque (1996) conducted several laboratory tests for geotechnical characterization; Monacci (1995) studied the soil as to its collapsibility. Paschoalin (2002) studied several characteristics of this soil in its “natural” and compacted condition in different moisture contents.

Gon (2011) collected samples down to 9-m depth at the FEC experimental site for tests of characterization, permeability, edometric, triaxial and proctor tests.

Based on these researches, it can be stated that the soil in the region under analysis comprises primarily one first layer of approximately 6.0 m of highly porous sandy clay; in some spots a 0.50-m layer of clayey-silty fine and medium sand can be found. There is a second layer of residual diabase soil composed of clayey sandy silt down to the depth of 16 m. The water table was not found down to this depth. Figure 4 shows this profile.

The first layer is formed by mature soil which underwent intense weathering. The second layer is formed by young residual soil, which has preserved inherited characteristics from the original rock (Albuquerque 2001). Figure 5 shows the geological profile of the Unicamp region (Barão Geraldo District).

Figures 6, 7, 8, 9 and 10 show results of field tests carried out by Carvalho et al. (2004) and resubmitted by Cury Filho (2016). Figures 6, 7 and 8 show average, maximum and minimum data of SPT index, Tmax e Tmin resistance of SPT-T.

Summary N resistance (Cury Filho 2016)

Summary of Tmáx resistance (Cury Filho 2016)

Summary of Tres resistance (Cury Filho 2016)

Figures 9 and 10 show results of static cone penetration tests (CPT) using electric cone, obtained by Carvalho et al. (2000). The average, minimum and maximum values of point resistance of the cone (qc) and lateral friction (fs) are shown.

Monacci (1995) and Gon (2011) carried out edometric compression tests in non-deformed samples, with flooding at different levels of stress to check soil collapsibility in conformance with Vargas method (1978).

According to Tables 1 and 2, most tests show that the soil under study is collapsible.

In order to analyze the influence of soil deformability both in its “natural” condition and after compaction when designing slabs on soil, the initial elasticity modulus was obtained via triaxial test.

Figure 11 shows the stress - strain behavior of a non-deformed sample collected at the depth of 1.0 m, with different stresses of confinement (Gon 2011). This Figure shows the initial modulus of deformability for stress of confinement of 100 kPa, resulting in the value of 3.3 MPa.

(Adapted from Gon 2011)

Stress-strain behavior of natural soil for the 1st meter

Figure 12 shows the stress - strain behavior of a sample of compacted soil at its optimal moisture of the Normal Proctor Test. Through these curves, the data in Table 3 was obtained, which shows the tensile strength and the value obtained for the initial modulus of elasticity for each confinement stress. This table demonstrates that the average value of the initial modulus of elasticity for the compacted soil was 22 MPa.

The increase of the modulus of elasticity due to compaction is about 6,7, similar the difference between a structural steel (E = 205 GPa) and a structural concrete (E = 30 GPa).

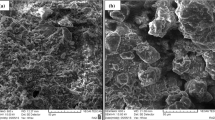

Figures 13 and 14 show the curves obtained by Paschoalin (2002) in the edometric test both for natural and compacted soil. A large reduction in voids can be seen when the soil is compacted.

Variation in the void index with addition of pressure for compacted soil (Paschoalin 2002)

Variation in the void index with addition of pressure for undisturbed soil (Paschoalin 2002)

Although compaction is a common method to improve most types of soil around the world, it is especially efficient for the studied soil.

Three CBR tests were performed with compacted soil in its optimal moisture. The results are described in Table 4. The average value is 4%.

1.4 Impact on Industrial Floors Design

When designing slabs on ground, whether for industrial floors, rigid pavements or radier-type foundations, in many methods the soil influences the dimensioning because of its deformability via consideration of the settlement coefficient k, also named vertical reaction modulus. In an elastic model, k, is the ratio between the stress applied on a point on the soil and the corresponding displacement.

One of the ways to get the modulus of vertical reaction of the soil (subgrade) is through correlation with the CBR index (ACI 360R-06). Figure 15 shows a curve relating the CBR index of the soil with k (Rodrigues et al. 2006). With this curve, it was possible to get the value of k of 33 MPa/m for the soil under study, considering the CBR index of 4%. Using this method is not possible to take into account the thickness of the compacted soil layer.

Correlation between CBR × k (Vaz Rodrigues et al. 2006)

Another form to get k is by means of a plate load test. There are standards that set a form to adopt k. For the specific purpose of designing rigid pavements, there is ASTM D 1196. In Brazil, there is standard 055-2004 ME of DNIT. Both standards determine a load test on a plate with 76 cm diameter and adopt as settlement coefficient the ratio of stress that causes settlement of 1.27 mm by the value of this settlement (Fig. 16).

Through the theory of elasticity, one can simulate the load test, if the modulus of elasticity of the soil is known, and get K for different conditions of the soil profile. Using the modulus of elasticity of the natural and compacted soil obtained via triaxial test (En = 3.3 MPa and Ec = 22 MPa), it was possible to get k for different thicknesses of compacted soil from zero to the 8-m layer. To do so, a soil profile with 8-m thickness on a non-deformed layer was adopted. Using the method of Janbu et al. (1956, apud Cintra 1998) k was obtained for different situations, including variation of Poisson’s coefficient of 0.20, 0.35 and 0.50. The results are shown in Table 5, which shows that k ranged from 5.6 MPa/m to 48.3 MPa/m.

Two situations of loading were used to assess the influence of variation of k in designing an industrial floor. The first situation is the case of a concentrated load of 50 kN applied by a tire with calibration pressure of 700 kPa. The second situation is the case of a distributed load of 40 kN/m2 with aisles without loading.

For the first case, the method of Meyerhof (1962) is used for floors with distributed reinforcement on the top, considering the load applied in the interior region of the floor (away from the edges of the plate). The bending moment acting in the concrete slab is obtained by means of Eq. 1, which, in turn, uses Eq. 2, which uses the modulus of elasticity of concrete of 26,840 MPa and Poisson’s coefficient of concrete of 0.20, where h is the thickness of the concrete of the industrial floor. In Eq. 1, ‘a’ is the radius of the area of contact between the tire and the industrial floor. Once the acting moment is obtained, the dimensioning is made by limiting the tensile stress in concrete by the admissible tensile stress in bending. For concrete of fck 30 MPa, an admissible stress of 2.07 MPa is adopted.

For the case of distributed load, the method of Packard (1996) is used. This method uses Eq. 3. C is the admissible distributed load, σadm is the admissible tensile stress of concrete (adopted 2.07 MPa), h is the thickness of concrete in cm and k is the coefficient of settlement in MPa/m.

Figure 17 shows the variation in thickness of a floor submitted to concentrated load with variation in the value of k. It can be noted that, even with such a large variation of k ranging from 5 to 50 MPa/m, the thickness of concrete varied approximately 1.20 cm, i.e., approximately 10%.

Figure 18 shows the same variation for distributed load, where the large influence of the value of k can be noted. By increasing 10 times its value, the thickness of the floor varied from 7 to 70 cm, which is directly proportional to the variation of k.

Considering two different support condition for an industrial floor: one without any compacted soil layer, the slab directly on the natural soil, and other with 1 m of compacted soil. Using the results presented in Table 5 (ν = 0,35) the k value for the first condition is 6,2 MPa/m, and 16,6 MPa for the second condition. With these K values, Fig. 17 shows that for concentrated load the slab thickness in a design would be 14 cm for both support conditions. Figure 18, for distributed load, shows for the first condition the slab thickness would be about 70 cm, and about 21 cm for the second support condition. The influence of the compacted soil in this case is huge.

2 Conclusions

Based on the results obtained, it can be stated that, for the soil under study, compaction improved the performance of the soil as to the following aspects:

-

Increased bearing capacity.

-

Increased rigidity and consequent reduction in strain due to stress.

-

Eliminated the collapsible characteristic of natural soil.

The soil under study is unsaturated, highly porous and collapsible. Its compaction is easy to be executed and cost-effective.

Compaction of collapsible surface soil is a solution that can make it possible to use shallow foundations in soils similar to the soil of the region under study, within certain limits of stress.

The layer of compacted soil significantly influences the value of the modulus of subgrade reaction for the soil under analysis.

For concentrated loads, the value of k has little influence on the industrial floors design, thus justifying the use of simpler methods to obtain it, such as the correlation with the CBR index. In these cases, the recommendation is a minimum layer of 20–25-cm thick compacted soil to even out the support and to get stabilization against collapse.

For distributed loads, the value of k has large influence on the industrial floors design, thus justifying the use of more reliable methods to obtain it, such as plate load tests.

The compacted soil layer affects strongly the slab support deformability for the studied soil.

References

Albuquerque, P.J.R.: Analysis of the behavior of instrumented driven piles of small diameters in diabasic residual soil of Campinas region. M.Sc. dissertation of Agriculture Engineering College, State University of Campinas (1996)

Albuquerque, P.J.R.: Bored piles, CFA and omega piles: study of the behavior subjected to compression in diabasic residual soil, through instrumented load test. Ph.D. thesis of Polytechnic School of São Paulo University (2001)

Bandeira, A.P.N., et al.: Characterization of collapsible soils in municipality of Juazeiro do Norte, interior of Ceará. Brazilian Congress of Soil Mechanics and Geotechnical Engineering, COBRAMSEG, ABMS, Porto de Galinhas (2012)

Carvalho, D., et al.: Experimental site for studies of soil mechanics and foundation in Campinas – SP. In: Seminar of Specials Foundation Engineering, vol. 4, São Paulo (2000)

Carvalho, J.M., Viana da Fonseca, A., Almeida, F., Hermosilha,H.: ISC’2 experimental site investigation and char acterization: conventional and to mographic P and S waves refraction seismics vs. electrical resistivity. In: Viana da Fonseca, A., Mayne, P.W. (eds.) Geotechnical and Geophysical Site Characterization. Millpress, Rotterdam (2004)

Cintra, J.C.A.: Foundation on Collapsible Soils, 1st edn. Graphical Service of Engineering School of São Carlos, University of São Paulo, São Carlos (1998)

Cintra, J.C.A., Aoki, N.: Foundation Design on Collapsible Soils, 1st edn. Graphical Service of Engineering School of São Carlos, University of São Paulo, São Carlos (2013)

Cury Filho, D.: Load capacity estimation for steel piles subjected to compression in diabasic soil of Campinas region. M.Sc. dissertation of Civil Engineering College, State University of Campinas (2016)

Ferreira, R.S.M.: Research report soil volume variation behavior due to flooding. Civil Engineering Department, UFP (2007)

Fontaine, E.B.: Utilization of specials field tests (electric cone and pressiometer test) for estimation of geotechnical properties and pile load capacity in some tropical soils. Ph.D. thesis of Agriculture Engineering College, State University of Campinas (2004)

Giachetti, H.L.: Experimental study of dynamic parameters of some São Paulo state tropical soils. Ph.D. thesis of Engineering School of São Carlos, University of São Paulo, São Carlos (1991)

Gon, F.S.: Geotechnical characterization through laboratory tests of a diabasic soil of Campinas region. M.Sc. dissertation of State University of Campinas (2011)

Guimarães, N., Ferreira, S.R.M.: Collapse due to flooding in compacted soils. Brazilian Congress of Soil Mechanics and Geotechnical Engineering, COBRAMSEG, ABMS, Brasília (1998)

Meyerhof, G.G.: Load-carrying capacity of concrete pavements. In: ASCE Proceedings (1950)

Monacci, M.D.: Study of soil collapsibility in experimental site of the Agriculture Engineering College – Unicamp. M.Sc. dissertation of the Agriculture Engineering College, State University of Campinas (1995)

Nogueira, R.C.R.: Behavior of root piles, instrumented, subjected ti axial compression, in diabasic soil. M.Sc. dissertation of Civil Engineering College, State University of Campinas (2004)

Packard, R.G.: Slab Thickness Design for Industrial Concrete Floors on Grade. Portland Cement Association, Concrete Information, Skokie (1996)

Paschoalin, J.A.: Study of different piles subjected to axial tensile in diabasic soil of Campinas region. Ph.D. thesis of State University of Campinas – Unicamp (2008)

Paschoalin, J.A.: Utilization of diabasic residual soil as foundation element and construction material of compacted embankments for small dams. M.Sc. dissertation of State University of Campinas – Unicamp (2002)

Peixoto, A.S.P.: Study of SPT-T test and its application in foundation engineering practice. Ph.D. thesis of Agriculture Engineering College, State University of Campinas (2001)

Junior, I.R., Futai, M.M.: Study case of collapsible soil improvement with compaction. In: Brazilian Congress of Soil Mechanics and Geotechnical Engineering, COBRAMSEG, ABMS, Gramado (2010)

Rodrigues, P.P.F., et al.: Gerdau Manual of Industrial Floors, 1st edn. Ed. Pini, São Paulo (2006)

Souza, A., Cintra, J.C.A.: Shallow foundation on collapsible soil of Ilha Solteira – SP. In: 10th Brazilian Congress of Soil Mechanics and Foundation Engineering, Foz do Iguaçu, vol. 1 (1994)

Vaz Rodrigues R., Muttoni A., Burdet O.: Large scale tests on bridge slabs cantilevers subjected to traffic loads. In: Proceedings of the 2nd fib Congress, vol. 1, p. 232, Naples (2006)

Acknowledgements

We wish to thank Vander Ferreira Alves, Iago Leandro dos Santos, Paulo Gustavo Krejci Nunes and Juliana Silva for their help in developing the tests.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Fonte, N.L., de Carvalho, D., Kassouf, R. (2018). Improvement of Collapsible Soil Conditions for Industrial Floors. In: Frikha, W., Varaksin, S., Viana da Fonseca, A. (eds) Soil Testing, Soil Stability and Ground Improvement. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-61902-6_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-61902-6_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61901-9

Online ISBN: 978-3-319-61902-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)