Abstract

Digital archiving has seen rapid growth in the recent years, accompanied by ever-increasing demands for high resolution and high-color definition color images. Despite the advances in imaging techniques, gold leaves and golden objects remain as some of the most difficult-to-image materials due to their highly reflective surfaces. Oversaturation commonly occurs when direct reflection is captured by an imaging element.

To solve this problem, we have developed a new scanner-type image acquisition method which can acquire high-resolution digital image and high-definition color information. In this paper, we outline the strategy employed in the new system to image gold, i.e., adjustment of light sources with respect to the sensor and use of polarizing filters to separate specular and diffuse reflection components.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Gold leaf

- High-color definition

- Saturation

- Line sensor camera

- Japanese-painting

- Polarization

- Shading

- Light source

- Imaging gold

- Digital museum

- Digital archiving

1 Introduction

Cultural assets that are known all over the world are being appreciated by many people by means of traveling exhibitions organized by art museums around the world. Due to the increasing demand for protection of art and cultural assets, more museums now choose to provide digital images of their collections on the internet, rather than subjecting the fragile objects to potentially damaging and risky journeys to other locations [1]. However, subjects having glossy surfaces such as gold leaf on Japanese paintings are notoriously challenging to image by conventional photography. A glossy subject causes specular reflection (direct reflection of source light incident upon the subject’s surface), creating saturated portions in the image (white stray) which contain no meaningful data. These glossy subjects are very sensitive to the angle of the incident light. Simply changing the image grabbing conditions such as closing the lens aperture or reducing the exposure time may eliminate saturation, however, the rest of the image becomes too dark and correct color information cannot be recorded [2].

In order to acquire a high-definition and high-quality image of this glossy subject, a new scanning system was devised where adjustable light source [3,4,5]. And a variable polarizing filter are used to capture specular reflection and diffuse reflection from the subject on separate images to represent fuller metallic luster information [6, 7]. The images are processed later to form a final image having more realistic visual appearance of the subject, making it suitable for uses in digital museums or reproductions.

Conventionally, two types of cameras i.e., line sensor type and area sensor type, are used for imaging. We used a line sensor camera to acquire high quality images in this research. There are two reasons for choosing a system featuring a scanning head with a line sensor camera. First, there is no inherent limit to the length of travel of the scanning head along the sub-scanning direction, provided that an appropriate gantry system and cabling are available. Second, generally speaking, line sensor cameras are capable of acquiring higher quality images more easily than area sensor cameras.

In this paper, we present a new scanning system for acquisition of high-resolution and high-definition digital color information on Japanese paintings decorated with gold foil by a line sensor camera, and demonstrate that we can obtain images containing only specular reflected light and images containing only diffuse reflected light by use of a polarizing filter oriented various angles.

2 Methods

2.1 Line Sensor Camera

In this section, we describe the design of a two-dimensional scanner to acquire an image of a large object with high-resolution and high-color definition. First of all, we write about the line sensor camera we used. The arrangement of the elements of the line sensor camera and the area sensor camera are shown in Fig. 1. In general, elements in an area sensor are arranged two-dimensionally, whereas the elements of the line sensor are one-dimensionally arranged in a single row. Therefore, to obtain a two-dimensional image using a line sensor camera, the line sensor camera itself needs to be moved perpendicular to the arrangement of the sensor element.

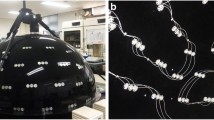

2.2 Scanner

In this section, we explain the line scanner for acquiring images of Japanese paintings decorated with gold leaf. The appearance of the scanner is shown in Fig. 2. Schematic diagrams of a scanner using a polarizing filter and a light source with a second polarizing filter are shown in Fig. 3. The camera was a line sensor camera TLC-7500CLD manufactured by Takenaka Co., Ltd. The lens system was composed of an Apo-Rodagon-N 105 mm F 2.8 and an 88 cm of extra tube. The resolution was set to 1100 DPI.

2.3 Shading

In line sensor cameras, dedicated light sources are used to improve color reproducibility, and color conversion is performed in consideration of spectral characteristics of the light sources and sensitivity characteristics peculiar to the camera to acquire accurate color information. One of the color transformations is shading correction. The shading correction is performed to reduce the influence of illuminance unevenness along the main scanning direction, sensitivity unevenness of the CCD pixel, peripheral light reduction of the lens.

A shading correction is performed in the following manner when an image of a two-dimensional plane is acquired by a line scanner. When acquiring an image of a two-dimensional plane by a line scanner, recording of data is performed while the camera and the light source sweep across the subject at the same time. Therefore, as shown in Fig. 4 (a), unevenness occurs in the main scanning direction. In order to reduce this unevenness, when capturing an image of a subject, a white reference image is captured at the same time as shown in Fig. 4 (b). Then, based on this reference white image, correction factors are calculated by the following formula so that the white reference image becomes uniformly white.

For the i th pixel in the main scanning direction, \( d_{cal}^{i} \) is the corrected value, \( {\text{d}}_{in}^{i} \) sensor response value of the image to be corrected, \( d_{wh}^{i} \) is the sensor response value of the castle reference image, \( d_{bk}^{i} \) is the sensor response value of the black reference image. Figure 4 (d) shows the results of correction using this equation. In a two-dimensional image, by using the above-described method, it is possible to obtain a color with uniform light intensity on the surface of the imaging object before color conversion.

2.4 Principle of Reflection Polarized Light Scanning

The imaging of a reflective metallic surfaces, such as the golden and the other metallic materials in a painting, has a challenge of how we can control the interactions of light and surfaces. The main parameters dominating these interactions are:

-

(1)

Surface structure (unevenness, roughness),

-

(2)

Incident direction (angle) of the light, and,

-

(3)

Polarization degree of the incident light.

In this paper we used two design features to successfully get good controlled images of big paintings with a metallic randomly oriented surface structure. The first feature was a linear sensor that gives us the controllability on collecting the reflected light on the image sensor and a polarization filter close to the linear sensor. The second feature was directional LED light as well as the polarization angle of the incident light. This technique cannot be used in imaging systems that have area sensors and randomly diffused incident ambient light sources. The basic criteria for design of our controlled and polarized light system was the near field light, and the geometrical design which gives us the ability to control the interaction of light and surface.

The reflection of light on the surface of the object can be explained using the dichroic reflection model as shown in Fig. 5. Light that is incident upon the surface of an object is repeatedly diffused and reflected inside elements within the surface. In addition to this diffuse reflected light appearing on the object surface, specular reflected light directly reflected by the object surface are also present, more noticeably on glossy surfaces. This diffuse reflected light is the original color of the object unaffected by the external environment, and the specular reflected light largely changes due to the influence of the external environment of the light source. Supposing that the intensity of specular reflection light is \( I_{supecular} \) and the intensity of diffuse reflection light is \( I_{diffuse} \), then the intensity \( I \) of the observed reflected light can be expressed as Eq. 2.

A polarizer is an optical element that allows components of light whose polarization is along that of the polarizer to pass through. In this study, a polarizing filter in the form of a film was used. Only light that oscillates in a specific direction is transmitted through the filter, and other components are absorbed. Therefore, when linearly polarized light of amplitude \( E_{0} \) is incident on the polarizing axis of the polarizer at an angle θ, the amplitude E after transmission is expressed by Eq. (3). Since the square of the amplitude of the light is the intensity of the light, the intensity \( I \) after passing through the polarizer is given by \( I_{0} \) as the intensity before transmission, it is expressed by Eq. (4).

Also, non-polarized light is light mixed with various linearly polarized lights, so it can be handled in the same way as circularly polarized light by taking a time average. Since circularly polarized light can be regarded as combined light of two orthogonal linearly polarized lights of the same intensity, if the intensity of the circularly polarized light before passing through the polarizer is \( I_{r0} \), \( I \) is expressed by Eq. (5).

From the above, the intensity of linearly polarized light and the intensity of non-polarized light were derived. In the dichroic reflection model, the component of the reflected light consists of two components, specular reflection and diffuse reflection as described in Eq. (2). Since the specular reflection is a reflection occurring at the boundary between the medium and the other medium, it can be described by the Fresnel equation below. Here, \( \theta_{\text{i}} , \theta_{\text{r}} \) represent the incident angle and refraction angle to the boundary, \( A_{\text{p}} , A_{\text{s }} \) are electric field vectors of incident light, \( R_{\text{p}} , R_{\text{s}} \) are parallel (p) and vertical (s). When \( \theta_{\text{i}} \) = \( \theta_{\text{r}} \) = 0 [deg], the reflection coefficient is expressed by (8).

In this paper, since \( n_{2} > n_{1} \), the reflection coefficient becomes negative, only the phase shifts by 180 [deg] at the boundary, and the intensity ratio of the parallel and the vertical components do not change. In other words, when linearly polarized light comes from above, the reflected polarized light oscillating in the same direction is the dominated component. Since the optical system used in this chapter is irradiated almost directly perpendicular to the imaging surface, the effect of angle of the polarizing filter attached to the light source can be neglected. When linearly polarized light is incident on the object from the light source side, the specular component of the light is reflected in the same direction as the polarization direction of the incident light. When observing this reflected light through the polarizer on the sensor side, the observed light intensity \( I_{\text{observe}} \) is the specular reflection component of light \( I_{\text{specular}} \), the diffuse component \( I_{\text{diffuse}} \), the angle between the axes of the two polarizing directions is defined as \( \theta \). Equation (9) shows the relation between the main components of the light using Eqs. (4) and (5).

This equation can be regarded as a linear model of intercept \( \frac{1}{2} I_{\text{diffuse}} \), gradient \( I_{\text{specular}} \), and independent variable \( \cos^{2} \theta \). Acquire two or more images with different values of \( \cos^{2} \theta \) (different angle \( \theta \)) and acquire the specular component and diffuse component by obtaining the intercept and the gradient. In this paper, by changing the angle of the polarizing filter by 90° at a time, a total of four images were acquired and a component separated image was acquired.

2.5 Gold Leaf Chart

In this paper, we used a gold leaf chart to scan gold leaf without color skipping. A gold leaf chart is a piece of gold leaf which is cut into small pieces and affixed on one piece of paper as shown in Fig. 6. We studied metallic foil materials which are used as art objects in the state of foil. For the gold foil, 6 types of gold foils with different gold purity and thickness were used, and for other metals, brass that is an alloy of copper and zinc and platinum foil were used [8,9,10]. The gold leaf chart was irradiated with light from a light source. Then, with any gold leaf, the amount of light that can be photographed was adjusted without color fading while leaving the metallic luster.

2.6 Light Source

In this paper, to obtain images expressing various metallic luster, a total of 3 patterns of light sources were created. A schematic diagram of the created light source is shown in Figs. 7 and 8. The CCT value of this LED light was 4000–4500 K. The distance between the subject and the light source was 185 mm. Figure 9 Shows the light source when polarizing filter is used. Only the upper light was used. The reason for this is to irradiate the subject with light directly from above. The distance from the subject was 60 mm.

3 Results and Discussion

Figures 10, 11 and 12 shows images scanned with different light source configurations, respectively. As can be seen from the image, it was possible to obtain images expressing various metallic luster by using different light sources. An image in which the spectral reflection component and the diffuse reflection component are separated using a light source filter is shown in Figs. 13, 14 and 15. It can be seen that separation was successful by the method proposed in this paper.

Japanese painting 1 (Left, 1 to 3 LED columns, Center 1 to 4 LED columns, Right 1 to 5 LED columns), 1100 DPI. The numbers show the LED light columns corresponding to Fig. 7.

Japanese painting 2 (Left, 1 to 3 LED columns, Center 1 to 4 LED columns, Right 1 to 5 LED columns), 1100 DPI. The numbers show the LED light columns corresponding to Fig. 7.

Japanese painting 3 (Left, 1 to 3 LED columns, Center 1 to 4 LED columns, Right 1 to 5 LED columns), 1100 DPI. The numbers show the LED light columns corresponding to Fig. 7.

4 Conclusion

The imaging of a reflective surface, such as the golden and other metallic materials in a painting is a question of how we can control the interactions of light and surface. The parameters governing these interactions are the surface structure (unevenness, roughness) and incident direction (angle) of the light and polarization degree of the incident light. In this paper we used two advantageous points to successfully get good controlled images of big paintings with a metallic randomly oriented surface structure. The first point is a linear sensor that gives us the controllability on collecting the reflected light on the image sensor and a polarization filter close to the linear sensor. The second point was a directional LED light as well as the polarization angle of the incident light. Obviously this technique cannot be used in imaging systems that have area sensors and randomly diffused incident light sources. The basic criteria for design of our controlled and polarized light system was the near field light, and the geometrical design which gives us the ability to control the interaction of light and surface.

In an experimental approach a new scanning system was designed and constructed and used in practice to accurately capture highly reflective surfaces such as gold leaves commonly found in Japanese paintings, and its capabilities were demonstrated. The scanner utilized light sources that are adjustable in flux, intensity and direction of the light as well as a rotatable polarizing filter. By controlling the relative direction of the polarized filters we can separate the specular reflection and diffuse reflection which differ in terms of intensity by orders of magnitude. In this paper, specular reflection and diffuse reflection were captured under various polarization degree and different images were grabbed. Then these images under various polarization degree were superimposed to obtain images which show the metallic parts with various intensity. However, some important problems remain in the image processing stage. It is practically difficult to determine the optimal polarization angle for each grabbed image, hence it was determined manually. The second problem is related to the positional accuracy of the scanner that causes mis-alignment in each scanned image.

References

Yastikli, N.: Documentation of cultural heritage using digital photogrammetry and laser scanning. J. Cult. Heritage 8(4), 423–427 (2007)

Kaneko, J., Toque, J.A., Murayama, Y., Ide-Ektessabi, A.: Non-destructive Analytical Imaging of Metallic Surfaces Using Spectral Measurements and Ultrahigh-resolution Scanning for Cultural Heritage Investigation (2011)

Toque, J.A., Murayama, Y., Ide-Ektessabi, A.: Polarized light scanning for cultural heritage investigation. In: Proceedings of SPIE, vol. 7869, 78690N (2011)

Murayama, Y.: Development of acquisition system of specular reflection component separated image using polarizer. Bachelor thesis, Kyoto University (2008). (in Japanese), (Henkousi wo motiita kyoumenhansyaseibun-bunrigazou no syutoku sisutemu no kaihatsu)

Ogino, R.: A high speed dynamic system for scanning reflective surface with rotating polarized filters. Master thesis, Kyoto University (2015). (in Japanese), (Rainsensakamera wo motiita dainamikku-firuta-sukyaningu-sisutemu no kaihatsu)

Ozawa, S.: Acquisition of three-dimensional shape and color information of golden large cultural property. Master thesis, Kyoto University (2016). (in Japanese), (Ougon-oogata-bunkazai no sanzigen-keizyou oyobi sikisaizyouhou no syotoku)

Ochi, K.: A system for simultaneous measurement of surface geometric and reflective optical properties using line sensors. Master thesis, Kyoto University (2016)

Shafer, S.: Using color to separate reflection components. Color Res. Appl. 10(4), 210–218 (1985)

Kitada, M., Kirino, H.: Kinnzoku ni Irodori wo Soeru Dentou Kougei Tyakusyuhou Hyoumenkagaku, 26(4), 226–230 (2005)

Ago, S., Tanaka, T., Yokote, T., Onodera, R.: Mechanics on Fabrication of Thin Metal Foils by Forging. In: The Japan Society of Mechanical Engineers, 7–8 (2002)

Acknowledgements

The paintings in this paper are art works of Ms. Masako Kurokawa, the models are Mameryu (painting 1), Manayo (painting 2), Aoitayuu (painting 3). We are very indebted to the artist and the models who gave us permission to use these invaluable images. We would like to thank Mr. Yusuke Isobe and Mr. Daichi Tsunemichi for discussion about the theory and the experiments, Ms. Mie Kado and Ms. Terumi Akasaka for valuable contribution and the staff in Ide-laboratory, Kyoto University for helping us to do the experiments.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Kanai, R., Kowada, Y., Wang, P., Toiya, M., Toque, J.A., Ide-Ektessabi, A. (2017). A Novel Scanning Technique for Imaging of Gold and Silver Foils Used in Art Works. In: Bianco, S., Schettini, R., Trémeau, A., Tominaga, S. (eds) Computational Color Imaging. CCIW 2017. Lecture Notes in Computer Science(), vol 10213. Springer, Cham. https://doi.org/10.1007/978-3-319-56010-6_13

Download citation

DOI: https://doi.org/10.1007/978-3-319-56010-6_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-56009-0

Online ISBN: 978-3-319-56010-6

eBook Packages: Computer ScienceComputer Science (R0)