Abstract

Alpine touring (AT) is a subdiscipline of alpine skiing where skiers ascend and descend snow slopes under their own power. Specialized equipment has been developed for AT skiing, including Tech/Pin bindings that rely on metal inserts molded into AT boots to rigidly couple the boot to the binding. The current lack of standardization has resulted in significant variation in tech insert geometry between boot manufacturers. A companion study examined the effects of inter-manufacturer variation of boots and bindings on the release characteristics of the toe piece of Tech/Pin bindings. This study continues this work and examines how inter-manufacturer variability affects the Tech/Pin boot-binding system as a whole, when both the toe and heelpiece are engaged.

The retention and release characteristics for an applied twisting torque were measured for the AT boots in the Tech/Pin binding toe pieces using an ASTM F504 test apparatus. Linear statistical models were developed to predict the measured retention-release behavior using the clamping force and tech insert geometry as predictor variables. The relative importance of each predictor variable from the linear model was then calculated.

Tech/Pin boot-binding systems have variations in release torque that exceed the minimum-maximum allowable release envelope prescribed by international standards. These variations stem from using boots from different manufacturers in a given binding. The indicator settings in these bindings do not change the release torque at the same proportional rate as other AT and alpine ski equipment. Skiers should not assume that Tech/Pin bindings will provide the same retention-release characteristics as alpine ski equipment, nor that the numerical indicator settings on Tech/Pin bindings are equivalent to alpine bindings. Homogenizing boot geometry would reduce the amount of variation in release torque from these boot-binding systems, but would not eliminate the problem completely, and could exacerbate the problems for users on one far end of the binding setting scale or the other.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Alpine touring (AT) is a subdiscipline of skiing in which the skier uses skis to ascend, traverse, and descend snow-covered terrain in the backcountry on unmaintained trails for which ski boot and binding manufacturers have developed specialized alpine touring equipment. For ascending uphill, skiers’ boots are attached to the ski by two pins on the binding toe piece that apply a compressive force to metal conical inserts in the boot toe. The toe piece can be locked during the ascent to eliminate the binding toe piece releasing from the boot. The binding heelpiece is engaged to secure the boot heel for descending slopes while performing alpine turns. In most Tech binding models, the retention-release performance for twisting and forward lean falls is controlled on the heelpiece. A spring-loaded cam mechanisms control the release torque. The preload on the spring is adjusted to indicator values (IV) that correspond to release torque values specified by international standards and are determined based on a skiers height, weight, boot size, and skier classification [1].

Anecdotal evidences suggests that many skiers leave the toe piece locked during the descent, against manufacturers recommendations, to eliminate the risk of an inadvertent release of the binding when a fall could result in injury or death. International standards have not yet been developed for the interface geometry of a subset of AT equipment, called Tech/Pin boot-binding systems. It is hypothesized that variations in boot-binding interface geometry diminishes their compatibility causing their release characteristics to be unpredictable. In turn skiers react to this unpredictability by locking the toe piece out, essentially blocking the release mechanism of the binding, and increasing the risk of injury in the event of a fall.

In a companion study, the relationship between variations in the interface geometry between the boot and binding toe piece, the resulting variations in release torque by quantifying the amount of variation in interface geometry, and constraint forces of the binding were explored. A twisting release torque was applied to the ski-boot-binding system with only the toe piece of the binding engaged with the boot. The amount of variation in boot geometry and binding constraint forces between manufacturers significantly affected the release torque of these systems. The geometry of these inserts are not defined in international equipment standards [2]. This study found that ~85% of the variation in release torque between AT boots from different manufacturers could be attributed to difference in two critical dimensions of the boot geometry, namely Dim A and Dim C (Fig. 1). The other ~15% of variation was a result of differences in the amount of clamping force the toe piece of the binding imposed on the boot.

This initial study provided a foundation for examining features critical for understanding the variation in release torque of Tech/Pin boot-binding systems. However, it was limited to the performance of the toe piece and serves as the motivation for the current study; to measure the effect of differences in boot-binding features on the variation in release torque of Tech/Pin boot-binding systems as a whole, with the toe and heelpieces are engaged.

2 Methods

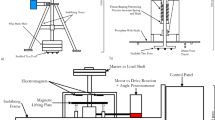

The release characteristics of Tech/Pin boot-binding systems were tested in a laboratory setting using a lower leg surrogate that conformed to standards ISO 9462:2012 Appendix B [3] and ASTM F504–05 [4]. For a complete description of the test methods and setup, please refer to our companion study. Three models of Tech/Pin ski bindings were selected for testing as representative of the principal toe piece mechanism currently on the market. Each binding was mounted to its own test ski; all test skis were the same make, model, and length 167 cm (AMP Rx, K2 Sports, Seattle, USA). Five models of AT boots with boot sole lengths between 306 and 310 mm were acquired for testing. A pure twisting couple or torque was applied to the ski-binding-boot system with the binding in four configurations tabulated in Table 1. The indicator setting marked on each binding was used to set each configuration. Each configuration was tested three times. Tests were performed dry, at 21 °C.

2.1 Multiple Linear Regression (MLR) Analysis

Independent variables, boot dimensions Dim A and Dim C and the clamping force associated with each boot-binding combination, were quantified in the previous study and used predict release torque in multiple linear regression (MLR) models for each binding and configuration listed in Table 1 (R , Foundation for Statistical Computing, Vienna, Austria, Fox, 2003). Data were centered about their mean and scaled by one standard deviation. The Kolmogorov-Smirnov test was employed to test for skewness. MLR analyses were used to predict release torque based on unique combinations of independent variables for each test configuration. The likelihood ratio test compared models using different independent variables and tested for interactions between independent variables. Variance inflation factors (VIF > 5) were used to identify regressors with high collinearity [5].

2.2 Relative Contribution of Regressors to MLR Models

The percent contribution to variation in release torque of each regressor in the MLR models was calculated using the lmg metric from the relaimpo statistical package in R [6]. The lmg metric normalizes R 2 to 100%, and the contribution of each regressor is calculated as a percentage of the R 2 from the linear model. The variance of percent contribution was calculated by bootstrapping the MLR models at 1000 bootstrap intervals, holding the regressors fixed and bootstrapping the residuals. The 95% bootstrap confidence intervals for regressors are reported in Appendix A, Table A.1.

2.3 MLR Coefficients

Coefficients from the MLR models were rescaled to observe how the sensitivity of the boot-binding to the independent variables changed as the binding heelpiece settings were increased.

3 Results

3.1 Release Torque

Release torque for configuration 1 (IV = 0, toe piece only) varied significantly between Binding 1 and Binding 3 (two-way Anova, Tukey’s Post Hoc Test, p < 0.001). The release torque for the other test configurations with the heelpiece at the minimum, median, and maximum settings increased linearly for all three bindings. However, they did not increase proportionally at the rate defined by international standards. A boxplot of the release torque from the three bindings and five boots in all four-test configurations is shown in Fig. 2. The shaded region defines the minimum-maximum release torque envelope for a given IV setting per ISO 13992:2014 [1]. The indicator settings of all three bindings do not increase the release torque at the same proportional rate as prescribed by international standards. A linear regression on the release torque vs. Indicator Value (not including test configuration 1, IV = 0), revealed that torque for Bindings 1, 2, and 3 increased at 35.4%, 55.9%, and 84.7% the rate prescribed by international standards, respectively (Appendix A, Table A.2).

Boxplots of the release torque of three bindings for configurations 1–4 overlaid with the minimum-maximum release envelope defined by ISO 13992:2014 for a twisting release torque. Boxplots at IV = 0 correspond to tests performed without the heelpiece engaged (toe piece only). Other plots are located on the x-axis corresponding to their IV setting (minimum, median, or maximum) for the heelpiece of each binding

The largest variance in release torque for Binding 1 was with the heelpiece setting at the maximum IV. Bindings 2 and 3 both had the largest variation in release torque when the heelpiece was not engaged (toe piece only). However, across the five boots tested in each binding, the variation in release torque at each indicator setting with the heelpiece engaged exceeded the minimum-maximum variation prescribed by the envelope shown in Fig. 2.

3.2 Predicting Release Torque from Boot-Binding Constraints

Using independent variables of clamping force and boot dimensions Dim A and Dim C, significant MLR models were found for each binding and configuration tested (Appendix A, Table A.3). The relative contribution of each independent variable is reported in Table A.3 and shown graphically in Fig. 3. The relative contribution of each independent variable is dependent on the heelpiece. As the indicator setting is increased, the heelpiece contributes more resistance to the release torque and the toe-piece dynamics change. The relative contribution to the variance in Torque of each independent variable was scaled to its contribution to the standard deviation, and the overall standard deviations with the absolute contribution of each boot-binding parameter overlaid in Fig. 4.

The standard deviation from each binding tested in each configuration, toe only (IV = 0), followed by IV = [Min, Median, Max] for each binding. The relative contribution of boot dimensions and the clamping force of each binding shown in Fig. 3 are scaled and plotted for each configuration. The notation “DimA|DimC” denotes the significant interaction between Dim A and Dim C from the MLR model

3.3 Binding Sensitivity to Boot-Binding Features

The effects or sensitivities from the MLR models are designated by the symbol β n , of each linear fit correspond to how the change in release torque, dT, is affected as a function of the change in each independent variable dDimA, dDimC, dF. The β n s of each MLR describe sensitivity of the release torque to changes in each of the parameters the coefficients are derived from. Figure 5 shows an exemplar MLR for the independent variables Dim A, Dim C, and Clamping Force regressing on the twisting release torque for all four-test configurations for Binding 3. Each β n outlined in Eqs. (1)–(3) represents the slope of the linear fit of the independent variable and response variable, torque.

Of particular interest is the change in each β n as the IV values were increased on the heelpiece. In Fig. 6, β DimA is plotted against β DimC for each test configuration and each binding. The origin of each plot represents the point at which the release torque of a binding would be invariant to changes in Dim A or Dim C; in other words, the slope β n would equal zero. Figure 6 shows that as the IV of the heelpiece increases, the overall sensitivity to changes in boot geometry decreases. In fact, for Binding 1, the sensitivity curve between IV = 5 and IV = 8.5 passes through the origin at IV = 7.5, assuming a linear relationship. Theoretically, at this discrete value of IV = 7.5, any of the five boots tested would all release at the same release torque value from Binding 1. However for any settings above IV = 7.5, the variation in Dim A and Dim C will have the opposite effect on release torque since the sensitivity curve passes from the upper left quadrant to the lower right quadrant. This could explain why the largest variation in release torque for Binding 1 was at the highest IV setting (Fig. 2).

The MLR coefficient β DimA (x-axis) is plotted against β DimC (y-axis) for each of the three bindings. The numbers aside each point indicate the corresponding Indicator Value of the binding (IV). IV = 0 indicates a test performed without the heelpiece engaged (toe piece only). Other numerical values represent the IV setting (minimum, median, or maximum) for the heelpiece of each binding

Extrapolating these observations to the plots for Binding 2 and Binding 3, the sensitivities of both bindings decrease and trend towards the origin, but do not intersect the origin at any point. The sensitivity curve for Binding 2 remains in the upper left quadrant but approaches the origin. Similarly for Binding 3, the sensitivity curve actually circles close to the origin, but never intersects it. Therefore, the variation in release torque will not be as significant between boots at higher IV settings for Bindings 2 and 3.

4 Discussion

The purpose of this two-part study aimed to quantify the amount of inter-manufacturer variability in release torque and determine specific parameters of the Tech/Pin boot-binding system that could possibly be optimized to performance of Tech boot-binding systems. Consumers perceive that Tech/Pin boot-binding systems have unreliable retention characteristics and often react by locking out the release function of their bindings. Given the amount of variation in release torque between boots shown in Fig. 2, this perception might have some merit. Lower leg injury rates stemming from an inadvertent release of a binding are slightly lower than rates associated with no-release of a binding during a fall [7]. However, both options (an inadvertent release or non-release) are considered to increase the risk of injury than if the release function of a binding adheres to international standards [8]. Furthermore, the results presented here in Fig. 2, show that indicator values marked on the Tech/Pin bindings tested did not correspond to the prescribed release torque by international standards. Consumers and professional ski mechanics should refer to ski binding test devices that conform to ISO 11110:2015 to set and verify proper binding release torque to the individual skier’s requirements, rather than assume the marked indicator settings will provide the appropriate release values.

Our previous companion study identified two boot measurements, Dim A and Dim C, as well as the clamping force from the binding that are strong predictors of release torque variability of the toe piece. This study has shown that while the boot parameters are still responsible for the bulk of the variability in release torque when the heelpiece of Tech/Pin bindings is engaged with the boot, the effect of these parameters changes as the indicator values on the heel are changed.

The sensitivity of each binding to differences in boot dimensions complicates an otherwise simple optimization problem due to the fact that the sensitivities themselves did change as a function of binding settings (Fig. 6). The lack of adjustability in most Tech/Pin binding toe pieces would limit the effectiveness of an optimization routine that identified values for Dim A and Dim C (among other possibilities) undertaken to reduce the amount of variation in release torque. If only boot dimensions are to be considered, one set of boot dimensions found to be optimal for lower IV settings would not be optimal for higher IV settings.

It is hypothesized that for Tech/Pin boot-binding systems to have retention-release characteristics similar to alpine ski boot-binding systems, improvement on current designs or new mechanisms for the toe piece will be necessary. There are currently two models of Tech/Pin bindings that utilize different mechanisms than the majority of bindings that incorporate indicator settings into the toe piece as well as the heelpiece. These designs are new do not have significant market share, and one of them utilizes different heel inserts than other bindings. Therefore, they were not considered by the authors to be representative of a sample of bindings on the market, and the authors do not speculate on their performance. However, it is likely that some ability to adjust the clamping force preload of the toe piece, the release load of the toe piece, and the dynamics of the toe piece based on the corresponding heelpiece dynamics will be necessary to reduce the variation in release torque in Tech/Pin boot-binding systems.

This study has not examined the effect of material hardness or loading conditions other than a pure twisting release. It is possible that other boot dimensions and binding features studied here are critical in other release modes or loading conditions. Furthermore, it will likely be impossible to optimize these systems until reaction forces transmitted from the ski to the boot through Tech/Pin bindings is directly measured such that the functional retention-release requirements of Tech/Pin boot-binding systems is clearly defined. Future laboratory testing on this subject could include dynamic impact tests to elucidate how the variables explored in our current study behave under dynamic loads of varying frequency and magnitude.

The mating interface geometry between alpine boots and bindings were homogenized by international standards in the 1980s; in turn, this normalized the retention/release characteristics. As a result, any alpine ski boot conforming to ISO 5355:2006 [9] from any manufacturer can be used with any alpine binding conforming to ISO 9462:2006 [3] from any manufacturer, without sacrificing retention/release performance. The results presented here show that retention/release characteristics of the Tech/Pin bindings tested, one of which was certified to ISO 13992:2014 by the Technischer Überwachungsverein, or TÜV, vary widely depending on which specific boot is being used and that Tech/Pin boot-binding systems do not provide the same retention/release characteristics as their Alpine boot-binding counterparts.

5 Conclusion

In summary, Tech/Pin boot-binding systems have variations in release torque that exceed the minimum-maximum allowable release envelope prescribed by international standards. These variations stem from using boots from different manufacturers in a given binding. The indicator settings in these bindings do not change the release torque at the same proportional rate as other AT and alpine ski equipment. Skiers should not assume that Tech/Pin bindings will provide the same retention-release characteristics as alpine ski equipment, nor that the numerical indicator settings on alpine bindings are equivalent to Tech/Pin bindings. Homogenizing boot geometry would reduce the amount of variation in release torque from these boot-binding systems, but would not eliminate the problem completely, and could exacerbate the problems for users on one far end of the binding setting scale or the other.

References

ISO 13992:2014(E) Alpine touring ski-bindings—requirements and test methods

ISO 9523:2008 Touring ski-boots for adults–interface with touring ski-bindings—requirements and test methods

ISO 9462:2006(E) Alpine ski-bindings—requirements and test methods

ASTM F504–05 (2005) Standard test method for measuring the quasi-static release moments of alpine ski. ASTM F504 1–12

O’Brien RM (2007) A caution regarding rules of thumb for variance inflation factors. Qual Quant 41(5):673–690

Grömping U (2006) Relative importance for linear regression in R: the package relaimpo. J Stat Softw 17(1):1–27

Shealy JE, Ettlinger CF, Johnson RJ (2005) Using signal detection theory as a model to evaluate release/retention criteria in alpine skiing. J ASTM International 2(7):1–12

Natri A, Beynnon BD, Ettlinger CF, Johnson RJ, Shealy JE (1999) Alpine ski bindings and injuries, current findings. Sports Med 28(1):35–48

ISO 5355:2006(E) Alpine ski-boots—requirements and test methods

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Appendix A: Statistical Tables

Appendix A: Statistical Tables

Rights and permissions

This chapter is distributed under the terms of the Creative Commons Attribution-Noncommercial 2.5 License (http://creativecommons.org/licenses/by-nc/2.5/) which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

The images or other third party material in this chapter are included in the work’s Creative Commons license, unless indicated otherwise in the credit line; if such material is not included in the work’s Creative Commons license and the respective action is not permitted by statutory regulation, users will need to obtain permission from the license holder to duplicate, adapt or reproduce the material.

Copyright information

© 2017 The Author(s)

About this paper

Cite this paper

Campbell, J.R., Scher, I.S., Carpenter, D., Jahnke, B.J., Ching, R.P. (2017). Interactions of Tech Bindings with AT Boot Toe Inserts: Part II Binding in Skiing Mode. In: Scher, I., Greenwald, R., Petrone, N. (eds) Snow Sports Trauma and Safety. Springer, Cham. https://doi.org/10.1007/978-3-319-52755-0_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-52755-0_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52754-3

Online ISBN: 978-3-319-52755-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)