Abstract

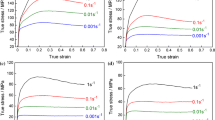

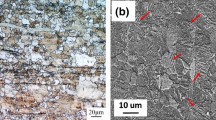

Forgeability of as-cast ZK60 magnesium alloy was investigated by isothermal uniaxial hot compression of cylindrical samples using the Gleeble® 3500 thermal-mechanical simulation testing system. Computational thermodynamics predictions (by FactSage™) along with differential scanning calorimetry (DSC) experiments showed incipient melting of low melting temperature precipitates in the as-cast material at around 340 °C. Therefore, the as-cast material was subjected to homogenization heat treatment at 400 °C for 4 h. Hot compression test were then conducted at 400 and 450 °C using a variety of strain rates (0.001–1.0 s−1). The microstructure of the samples deformed at low strain rates consisted of dynamically recrystallized (DRXed) grains. By increasing the strain rate, the volume fraction of the DRXed regions reduced. The material also exhibited sensitivity to deformation temperature in terms of DRX volume fraction. Texture of the deformed samples was also characterized using the XRD method to investigate the effect of hot deformation conditions on the texture evolution.

Bruce W. Williams: Majesty the Queen in Right of Canada, as represented by the Minister of Natural Resources, 2016.

Similar content being viewed by others

References

T.M. Pollock, Weight loss with magnesium alloys. Science 328, 986–987 (2010)

A.A. Luo, Magnesium: current and potential automotive applications. JOM 54(2), 42–48 (2002)

R. Gehrmann, M.M. Frommert, G. Gottstein, Texture effects on plastic deformation of magnesium. Mater. Sci. Eng. A 395, 338–349 (2005)

T. Al-Samman, G. Gottstein, Room temperature formability of a magnesium AZ31 alloy: examining the role of texture on the deformation mechanisms. Mater. Sci. Eng. A 488, 406–414 (2008)

H. Chen, S.B. Kang, H. Yu, J. Cho, H.W. Kim, G. Min, Effect of heat treatment on microstructure and mechanical properties of twin roll cast and sequential warm rolled ZK60 alloy sheets. J. Alloy. Compd. 476, 324–328 (2009)

J.D. Robson, C. Paa-Rai, The interaction of grain refinement and ageing in magnesium–zinc–zirconium (ZK) alloys. Acta Mater. 95, 10–19 (2015)

FactSage™, Ver. 6.2. Thermfact (Montreal, Canada) and GTT-Technologies (Aachen, Germany) (1976–2010)

W. Yu, Z. Liu, H. He, N. Cheng, X. Li, Microstructure and mechanical properties of ZK60–Yb magnesium alloys. Mater. Sci. Eng. A 478, 101–107 (2008)

Y.J. Qin, Q.L. Pan, Y.B. He, W.B. Li, X.Y. Liu, X. Fan, Modeling of flow stress for magnesium alloy during hot deformation. Mater. Sci. Eng. A 527, 2790–2797 (2010)

S.I. Kim, Y.C. Yoo, Dynamic recrystallization behavior of AISI 304 stainless steel. Mater. Sci. Eng. A 311, 108–113 (2001)

G.Z. Quan, Y. Shi, Y.X. Wang, B.S. Kang, T.W. Ku, W.J. Song, Constitutive modeling for the dynamic recrystallization evolution of AZ80 magnesium alloy based on stress–strain data. Mater. Sci. Eng. A 528, 8051–8059 (2011)

H. Li, E. Hsu, J. Szpunar, R. Verma, J.T. Carter, Determination of active slip/twinning modes in AZ31 Mg alloy near room temperature. J. Mater. Eng. Perform. 16(3), 321–326 (2007)

M. Sanjari, A.S.H. Kabir, A. Farzadfar, H. Utsunomiya, R. Petrov, L. Kestens, S. Yue, Promotion of texture weakening in magnesium by alloying and thermomechanical processing. II: rolling speed. J. Mater. Sci. 49, 1426–1436 (2014)

M. Sanjari, S.A. Farzadfar, I.H. Jung, E. Essadiqi, S. Yue, Influence of strain rate on hot deformation behaviour and texture evolution of AZ31B. Mater. Sci. Technol. 28(4), 437–447 (2012)

Acknowledgements

The authors would like to appreciate the financial support from the NSERC—Automotive Partnership Canada. One of the authors (AH) would like to thank Mr. Mark Whitney at the University of Waterloo for his assistance for running the Gleeble machine and Dr. Renata Zavadil at CanmetMATERIALS for her assistance for metallographic sample preparation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Hadadzadeh, A., Shaha, S.K., Wells, M.A., Jahed, H., Williams, B.W. (2017). Microstructure and Texture Evolution During Hot Deformation of Cast-Homogenized ZK60 Magnesium Alloy. In: Solanki, K., Orlov, D., Singh, A., Neelameggham, N. (eds) Magnesium Technology 2017. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52392-7_70

Download citation

DOI: https://doi.org/10.1007/978-3-319-52392-7_70

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52391-0

Online ISBN: 978-3-319-52392-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)