Abstract

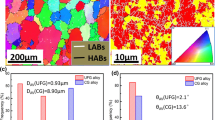

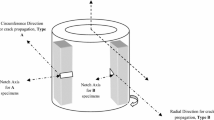

The degradation of grain boundary strength induced by corrosion is one of the causes of intergranular stress corrosion cracking. The micro tensile testing method for measuring the strength of an individual grain boundary was applied to alloy 600 specimens exposed to simulated PWR primary water. The exposure caused grain boundary oxidation that progressed about 0.2 µm perpendicular to the boundary; and depending on the exposure time, the depth can be over 2 µm. Specimens of dimensions 1×2×4 µm containing one grain boundary were made by focused ion beam (FIB) micro-processing and were tested in tension in an FIB system. Intergranular fracture occurred at 180–300 MPa for an oxidized grain boundary while it did not occur even at 1000 MPa for a non-oxidized grain boundary. It was confirmed by transmission electron microscopy (TEM) that the cracking propagated on the interface between the metal matrix and the intergranular oxide.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

L.E. Thomas and S.M. Bruemmer, “High-resolution Characterization of Intergranular Attack and Stress Corrosion Cracking of Alloy 600,” Corrosion, 56 (2000), 572–587.

K. Fujii, K. Fukuya, and N. Nakajima, “Evaluation of Surface Oxidation Mechanism of Alloy 600 in a Simulated Primary Water of Pressurized Water Reactors Using Analytical Transmission Electron Microscopy,” Transactions of the Atomic Energy Society of Japan, 1 (2002), 127–133.

J. Panter, B. Viguier, J.-M. Cloué, M. Foucault, P. Combrade, and E. Andrieu, “Influence of Oxide Films on Primary Water Stress Corrosion Cracking Initiation of Alloy 600,” Journal of Nuclear Materials, 348 (2006), 213–221.

T. Terachi, N. Totsuka, T. Yamada, T. Miyamoto, M. Ozawa, and K. Nakata, “Comparison of LPSCC Crack Tips of Alloy 132 and Alloy 600 — Influence of Dissolved Hydrogen -,” CORROSION/2009, NACE , Paper No. 09413, (2009).

P.M. Scott and M. LeCulvar, “Some Possible Mechanisms of Intergranular Stress Corrosion Cracking of Alloy 600 in PWR Primary Water,” Proceeding of 6th International Symposium on Environmental Degradation of Materials in Nuclear Power Systems — Water Reactors, (1993), 675–665.

R.W. Staehle and Z. Fang, “Comments on a Proposed Mechanism of Internal Oxidation for Alloy 600 as Applied to Low Potential SCC,” Proceeding of 9th International Symposium on Environmental Degradation of Materials in Nuclear Power Systems — Water Reactors, (1999), 69–77.

R.C. Newman, T.S. Gendron, and P.M. Scott, “Internal Oxidation and Embrittlement of Alloy 600,” Proceeding of 9th International Symposium on Environmental Degradation of Materials in Nuclear Power Systems — Water Reactors, (1999), 79–92.

K. J. Hemker and W.N. Sharpe Jr., “Microscale Characterization of Mechanical Properties,” Annual Review of Materials Research, 37 (2007), 93–126.

D. Kiener, C. Motz, and G. Dehm, “Micro-Compression Testing: A Critical Discussion of Experimental Constraints,” Materials Science and Engineering A, 505 (2009), 79–87.

D.S. Gianola and C. Eberi, “The Micro- and Nanoscale Tensile Testing of Materials,” JOM, 61, 3 (2009), 24–35.

S. Orso, U.G. Wegst, C. Eberl, and E. Arzt, “Micrometer-Scale Tensile Testing of Biological Attachment Devices,” Advanced Materials, 18 (2006), 874–877.

K. Fujii and K. Fukuya, “Development of Micro Tensile Testing Method in an FIB System for Evaluating Grain Boundary Strength,” Materials Transactions, 52 (2011), 20–24.

J.A. Gorman, “Status and Suggested Course of Action for Nondenting-Related Primary-Side IGSCC of Westinghouse-Type Steam Generators,” EPRI, Report MP-4594-LD, (1986).

N. Totsuka, Y. Nishikawa, M. Kamaya, and N. Nakajima, “Evaluation of Lifetime and Effects of Hydrogen on PWSCC of Nickel Based Alloy,” Proceeding of International Symposium on Mechanisms of Material Degradation and Non-Destructive Evaluation in Light Water Reactors, INSS, Japan, (2002), 199–213.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Fujii, K., Miura, T., Nishioka, H., Fukuya, K. (2011). Degradation of Grain Boundary Strength by Oxidation in Alloy 600. In: Busby, J.T., Ilevbare, G., Andresen, P.L. (eds) Proceedings of the 15th International Conference on Environmental Degradation of Materials in Nuclear Power Systems — Water Reactors. Springer, Cham. https://doi.org/10.1007/978-3-319-48760-1_89

Download citation

DOI: https://doi.org/10.1007/978-3-319-48760-1_89

Publisher Name: Springer, Cham

Online ISBN: 978-3-319-48760-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)