Abstract

Many papers have reported about the effects of strain hardening by cold rolling, grinding, welding, etc. on stress corrosion cracking susceptibility of nickel based alloys and austenitic stainless steels for LWR pipings and components. But, the residual strain value due to cold rolling, grinding, welding, etc. is not so quantitatively evaluated.

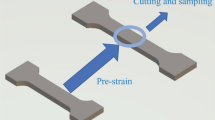

Therefore, authors quantitatively measured and evaluated the residual strain value for strain hardened tensile or torsion specimens of nickel based alloys by applied strain, FWHM of gamma X-ray diffraction, EBSD and Vickers’ hardness measurement to make a calibration curve, at first. Using these curves, the residual strain in the heat affected zone of weld joint and cold worked plates, etc., was quantitatively evaluated from the measuring data of Vickers’ hardness or EBSD or FWHM of gamma peak in X-ray diffraction. As a result, residual strain value in the heat affected zone of weld joint was evaluated as about 10% of von Mises equivalent strain from FWHM, EBSD and Vickers’ hardness measurement. But the residual strain of the 20% and 30 % cold rolled Alloy 600 or TT690 were evaluated about 40% and 60 % of von Mises equivalent strain, respectively.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

K.Arioka et al.: Corrosion (2006), p.568.

2) P.Andresen: Fontevraud 7 (2010), CD-Rom

D.Tice et al.: Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System — Water Reactors — (2005), p.1037

K.Arioka et al.: Corrosion (2008), p.691.

N.Matsubara et al.: Fontevraud 7 (2010), CD-Rom

G.E.Dieter: Mechanical Metallurgy, SI Metric Edition, McGraw-Hill Book Company, (1988)

G.Was: Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System — Water Reactors — (2005), p.1343

Y.Takeda et al.: Proceedings of the ASME 2010 Pressure Vessels & Piping Division / K-PVP Conference (2010), Bellevue, Washington, USA

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Yonezawa, T., Maeguchi, T., Goto, T., Juan, H. (2011). Quantitative Residual Strain Analyses on Strain Hardened Nickel Based Alloy. In: Busby, J.T., Ilevbare, G., Andresen, P.L. (eds) Proceedings of the 15th International Conference on Environmental Degradation of Materials in Nuclear Power Systems — Water Reactors. Springer, Cham. https://doi.org/10.1007/978-3-319-48760-1_104

Download citation

DOI: https://doi.org/10.1007/978-3-319-48760-1_104

Publisher Name: Springer, Cham

Online ISBN: 978-3-319-48760-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)