Abstract

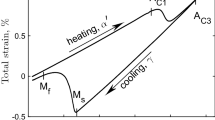

Dynamic mechanical behavior is vital to the investigation of mechanism of material removal in heavy grinding process, especially for manufacturing the root of turbine blades. The effect of temperature on properties is a key factor in the process, which may reach above the point of phase transformation. In this paper, dynamic mechanical experiments were conducted in elevated temperatures starting ambient temperature through complete austenitizing point, even the overcooling austenite, with a strain rate ranging from quasi-static to 8000s−1 with Split Hopkinson Pressure Bar. Kinetics of austenization was involved to investigate the effect of phases on the property. A comprehensive constitutive model was proposed to describe the dynamic mechanical behavior with temperature, strain rate and phase fraction consideration. The model was validated through comparison between experimentation and computation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Yan, L., F. Jiang, and Y. Rong, Grinding Mechanism Based on Single Grain Cutting Simulation. Journal of Mechanical Engineering, 2012. 48(11): p. 172–182.

Yan, L., F. Jiang, and Y. Rong, Grinding Mechanism Based on Single Grain Cutting Simulation. Journal of Mechanical Engineering, 2012. 48(11): p. 172–182.

Wang, X., et al., Dynamic behavior and a modified Johnson-Cook constitutive model of Inconel 718 at high strain rate and elevated temperature. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, 2013. 580: p. 385–390.

Lee, W.S. and C.W. Chen, Dynamic mechanical properties and microstructure of Ti-6Al-7Nb biomedical alloy as function of strain rate. Materials Science and Technology, 2013. 29(9): p. 1055–1064.

Song, R.-b. and Q.-f. Dai, Dynamic Deformation Behavior of Dual Phase Ferritic-Martensitic Steel at Strain Rates From 10(-4) to 2000 s(-l). Journal of Iron and Steel Research International, 2013. 20(8): p. 48–53.

Sun, H.T., et al., Application of warm forming aluminum alloy parts for automotive body based on impact. International Journal of Automotive Technology, 2013. 14(4): p. 605–610.

Zhongbin, Z., C. Pengwan, and H. Fenglei, Study on dynamic fracture and mechanical properties of a PBXsimulant by using DIC and SHP B method. AIP Conference Proceedings, 2012. 1426: p. 665–8.

Prawoto, Y., et al., Computational approach using Johnson-Cook model on dual phase steel. Computational Materials Science, 2012. 54: p. 48–55.

Li, H.-Y., et al., A modified Johnson Cook model for elevated temperature flow behavior of T24 steel. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, 2013. 577: p. 138–146.

Zhang, W., J.W. Elmer, and T. DebRoy, Kinetics of ferrite to austenite transformation during welding of 1005 steel. Scripta Materialia, 2002. 46(10): p. 753–757.

Kissinger, H.E., Reaction Kinetics in Differential Thermal Analysis. Anal. Chem., 1957. 29(11): p. 1702–1706.

Jian-sheng, C.R.-k.G.J.-f.H.L.-z.P., Austenitization kinetics of 30Cr2Ni4MoV steel. Transctions of aterials and heat treatment, 2013. 34(1): p. 170–174p.

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2014 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Nie, Z., Wang, G., Yu, J., Rong, Y.K. (2014). Dynamic Mechanical Behavior and Phase-Based Constitutive Model of 20Cr12Ni4Mo3VNiN in Austenitizing Stage. In: TMS 2014: 143rd Annual Meeting & Exhibition. Springer, Cham. https://doi.org/10.1007/978-3-319-48237-8_134

Download citation

DOI: https://doi.org/10.1007/978-3-319-48237-8_134

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48593-5

Online ISBN: 978-3-319-48237-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)