Abstract

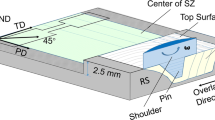

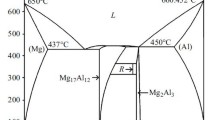

Friction Stir Processing (FSP) to partial sheet thickness can be utilized to engineer unique microstructures in metallic alloys. These composite microstructures consist of three distinct layers associated with stirred, transition and core micro structural regions. The stirred region is of particular interest where severe plastic deformation imparted by the rotating and translating FSP tool under frictional heat leads to grain refinement down to ~ 1 urn grain size. In this work, partial depth penetration into thixomolded AZ91 Mg plate from the top and bottom surfaces by friction stir processing is explored. Furthermore, low temperature aging treatments are applied to the processed material. The present results with AZ91 Mg show that FSP processed material exhibits higher strength (> 300 MPa), and improvement in ductility (> 7 % tensile elongation). It is found that in addition to Hall-Petch strengthening produced by ~ 1 um grain size in the stirred region, the enhanced strength levels and ductility are strongly influenced by dispersoids of the intermetallic precipitates found in this alloy.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

B. L. Mordike and T. Ebert “Magnesium properties-applications-potential,” Materials Science & Engineering A, 302 (2001), 37–45.

J. Goken J. Bohlen N. Hort D. Letzig and K. U. Kainer “New development in magnesium technology for light weight structures in transportation industries,” Material Science Forum, 426(2003), 153–160.

E. F. Emley Principles of Magnesium Technology (Oxford, UK: Pergamon Press Ltd., 1966), 1013.

V. M. Segal “Materials processing by simple shear,” Materials Science & Engineering A, 197(1995), 157–164.

R. Z. Valiev A. V. Korznikov and R. R. Mulyukov “Structure and properties of ultrafine-grained materials produced by severe plastic deformation,” Materials Science & Engineering A, 168(1993), 141–148.

Y. Saito N. Tsuji H. Utsunomiya T. Sakai and R. G. Hong “Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process,” Scripta Materialia, 39(1998), 1221–1227.

L. Sturkey and J. B. Clark “Mechanism of age-hardening in magnesium-zinc alloys,” Institute of Metals - Journal, 88(1959), 177–181.

M. Mabuchi K. Ameyama H. Iwasaki and K. Higashi “Low temperature superplasticity of AZ91 magnesium alloy with non-equilibrium grain boundaries,” Acta Materialia, 47(1999), 2047–2057.

A. Galiyev R. Kaibyshev and G. Gottstein “Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60,” Acta Materialia, 49(2001), 1199–1207.

M. T. Pérez-Prado J. A. del Valle and O. A. Ruano “Grain refinement of Mg-Al-Zn alloys via accumulative roll bonding,” Scripta Materialia, 51(2004), 1093–1097.

P. B. Berbona W. H. Bingela R. S. Mishra C. C Bamptonc M. W. Mahoney “Friction stir processing: a tool to homogenize nanocomposite aluminum alloys,” Scripta Materialia, 44(2001), 61–66.

J. Campbell “Rheocasting and Thixocasting - a review of progress to-date” Foundry Trade Journal, 138(1975), 291–295.

L. Pasternak R. D. Carnahan R. F. Decker R. Kilbert “Semisolid production processing of magnesium alloys by Thixomolding,” Proceedings of the 2nd International Conference on Processing of Semi Solid Alloys and Composites, 1993, 159–169.

R. F. Decker R. D. Carnahan E. Babij J. Mihelich G. Spalding and L. Thompson “Magnesium semi-solid metal forming,” Advanced Materials & Processes, 149(1996), 41–42.

B. Mansoor “Microstructural evolution and mechanical properties of high strength Mg alloys fabricated by deformation processing”(Ph.D. thesis Univ. of Michigan, Ann Arbor, 2010), 39–72.

S. H.C. Park Y. S. Sato and H. Kokawa “Microstructural evolution and its effect on Hall-Petch relationship in friction stir welding of thixomolded Mg alloy AZ91D,” Journal of Material Science, 38 (2003), 4379–4383.

J. A. Esparza W. C. Davis and L. E. Murr “Microstructure-property studies in friction-stir welded, Thixomolded magnesium alloy AM60,” Journal of Material Science, 38 (2003), 941–952.

Y. S. Sato S. H.C. Park A. Matsunaga A. Honda and H. Kokawa “Novel production for highly formable Mg alloy plate,” Journal of Material Science, 40 (2005), 637–642.

M. Santella A. Frederick C. Degen and TY. Pan “The use of friction-stir technology to modify the surfaces of AM60B magnesium die castings,” JOM, 58(2006), 56–61.

Welding Processes, Chapter 7 (212–258), AWS Welding Handbook, Vol. 3, Part 2, 7th Ed. (Miami, FL, USA: American Welding Society, 2007).

B. M. Darras M. A. Omar and M. K Khraisheh “Experimental thermal analysis of friction stir processing,” Material Science Forum, 539(2007), 3801–3806.

S. H.C. Park SY. Sato and H. Kokawa “Microstructural evolution and its effect on Hall-Petch relationship in friction stir welding of thixomolded Mg alloy AZ91D,” Journal of Material Science, 38(2003)4379–4383.

A. Stevenson Heat Treating of Magnesium Alloys (899–906), ASM Handbook Vol. 4, 9th Ed., (Materials Park, OH, USA: ASM International, 1990).

Y. Z. Lu Q. D. Wang W. J. Ding X. Q. Zeng and Y. P. Zhu “Fracture behavior of AZ91 magnesium alloy,” Materials Letters, 44(2000), 265–268

Y. Wang G Liu, Z. Fan “Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment,” Acta Materialia, 54 (2006), 689–699.

E. O. Hall “The deformation and ageing of mild steel III. Discussion of results” Proceedings of the Physical Society. Section B, 64 (1951), 747–753.

N. J. Petch “Cleavage strength of polycrystals,” Iron and Steel Institute- Journal, HA (1953), 25–28.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Mansoor, B., Decker, R.F., Kulkarni, S., LeBeau, S.E., Khraisheh, M.K. (2012). The Effect of Friction Stir Processing on Microstructure and Tensile Behavior of Thixomolded AZ91 Magnesium Alloy. In: Mathaudhu, S.N., Sillekens, W.H., Neelameggham, N.R., Hort, N. (eds) Magnesium Technology 2012. Springer, Cham. https://doi.org/10.1007/978-3-319-48203-3_69

Download citation

DOI: https://doi.org/10.1007/978-3-319-48203-3_69

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48571-3

Online ISBN: 978-3-319-48203-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)