Abstract

Quartz glass has a very high purity of silicon, and has heat resistance, chemical resistance, and excellent optical transparency. Therefore, it has been called the king of the glass.

Quartz glass has a superior performance than other glasses. Especially it has been used as a key component of high-performance analytical instruments and scientific instruments and special manufacturing equipment.

Because of its high heat resistance, it is difficult to the processing in a variety of shapes. General borosilicate glass can be mass produced by a hot press processing with precision mold. Quartz glass is difficult to mass-produced by mold because of its high melting point. Therefore, many of the quartz glass product is manufactured by engineer’s hand processing for each product.

Therefore, in order to produce high-precision quartz glass product efficiently, engineers training is the most important. Also, engineers with a high processing technology has been aging in recent years. There are situations in which the tradition of technology is not going well. To keep stable supply of high-precision products, to analyze the processing technology of highly skilled engineers, it requires efforts to help education and training.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

There are several types of the processing of quartz glass. Especially, products used in such analysis equipment, special and complicated shapes are required. Therefore, the heating processing by flame called “Fire-process” is needed.

“Fire-process” is a processing technology that uses a mixed flame of oxygen and hydrogen by heating the quartz glass material to the softening point, to form the softened glass by hand of the engineer. Therefore, to produce high-precision products efficiently it is believed to require special processing technology by many years of experience.

Bending is one of the basic processing technology among fire processing of quartz glass. The bending is a general term for the process of bending at an angle while heating the quartz glass. This technique is used in many products, this technique is essential in the production of complex glass parts used in the analyzer.

In this study, we took up this bending process. This technique is one of the basic processing techniques, it has been made by hand. Also, this process is dependent on the quality and work efficiency by the skill of the engineer. In the current situation, that the low skilled engineers to copy the processing steps have not been able to improve the quality and productivity. On the basis of this situation, the purpose of this study, by the quartz glass bending process analysis under the same conditions by different engineers, is to help the results to the training of future engineers.

2 Experimental Method

This section describes the experimental method of bending.

We chose the engineers of two people with different years of experience as a subject.

Two of the engineers did a bending under the same conditions, and analyzed the process by the video shooting.

The experiment material was normal quartz glass tube with outside diameter: 20 mm, inside diameter: 17 mm, length: 400 mm.

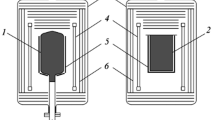

Before bending process, engineers join the glass tube for holding to two ends of quartz glass tube. (Fig. 1).

The status of operator and burner is shown in Fig. 2.

The flame with about 3000 °C which can soften the quartz glass was generated by the combination of hydrogen and oxygen. Operator sat behind the burner and kept sitting posture for processing.

Engineers were directed to perform bending process on quartz glass tube to 90 ° without any other instruction. Meanwhile, each subjects processed one piece of tube at a time and totally 3 times. During process, every experimental subject was controlled in same process environment without distraction. This is so that the subject is not affected by watching the processing techniques of the other subjects. In order to analyze the detail, the whole process was recorded by digital camera.

3 Engineer’s Information

In this study, two different experience engineers were invited as subjects who “Engineer-A” has 54 years of experience, “Engineer-B” has 5 years of experience. Two were selected from engineers who works on fire process every day and their experiment of processing was continuous for many years.

4 Motion Analysis

Firstly, we have analyzed the processing recorded video, were compared for time from start to finish. (Fig. 3).

Firstly, subjects were heated while rotating the quartz glass tube in the axial direction by hand. And After heating, engineer A was bent 90 ° by one of the bending motion. Engineer B was bent 90 ° by the number of times of bending motion. The number of the bending motion is shown in Fig. 4.

Next, we investigated the difference of heating points and heating time of the glass tube in each subject. The glass tube is divided in four areas (Fig. 5), and measures the heating time by the burners in each area. (Fig. 6).

In the case of Engineer-A, it was processed in a single bending motion. In that case, the glass tube before bending motion had been evenly heated.

In the Engineer-B case, it had been processed in several times of bending motion. In that case, the processing time becomes relatively longer. Addition, it was found that the glass tube is not evenly heated before bending motion.

5 Measurement of Bending Part

Next, we investigated the quality of the quartz glass tube after bending. There are several quality standards for Glass products needs the bending processing. In this study, we measured the outer diameter and wall thickness of the glass tube.

The amount of change before and after processing is the basis for the evaluation of the processing quality.

The image of the quartz glass tube after bending is shown in Fig. 7. Also it shows the measurement points of the outer diameter in Figs. 8 and 9 shows the change in the outer diameter before and after processing.

In the case of Engineer-A, the diameter of the glass tube was reduced in the X direction. In the Engineer-B cases, the diameter was expanded. Y direction of the trend was the same as the X direction. In the case of Engineer-A, reduced diameter of the glass tube, in the Engineer-B case, the diameter of the glass tube is expanded. (Fig. 10).

The following were the measurement of wall thickness. Figure 11 shows the measurement point. We cut the glass tube, and measured wall thickness with a digital caliper. (Fig. 12).

In both cases the Engineer-A and -B, the thickness of the C section is thinned in comparison with the wall thickness of the Original. C section had been stretched most at the time of bending. Engineer-A’s C section reduction of wall thickness was less.

Addition, Eng-B cross section of the bending is deformed. (Fig. 13) On the other hand, Eng-A’s cross-section deformation is small. Eng-A was able to bending with a high roundness.

6 Consideration

In this study, the differences in the working process and the product quality between engineers with different years of experience during the ‘fire-process’ of quartz glass material were analyzed.

As for product quality, the researches and engineers watched the records after experiment, and engineer-A dictated that the wall thickness, outside diameter of quartz glass tube determined the product quality. Engineer-A told, outside diameter of heated tube will shrink at the beginning of the process. If the tube was heated the outside diameter would shrink and the tube wall would be thicker. Above phenomenon is called ‘collect the thickness’. If the tube was stretched the outside diameter would shrink and the tube wall would be thinner, on the contrary, if the tube was compressed to center the outside diameter would expand and the tube wall would be thicker.

In bending process, bending inside part is compressed which cause tube wall thicker, and bending outside part is stretched which cause tube wall thinner. When Eng-A rotate and heat the tube, consciously conducting ‘collect the thickness’. Eng-A was able to make a bending products of stable quality because the thickness was conscious control.

In addition, the change in outer diameter of the horizontal (Axis-X of Fig. 8) is generated. (see Fig. 9) Expansion of Axis-X direction, could be confirmed by the glass tube after processing of Eng-B.

By interview, Eng-A had assumed the change. When tube was heated and the outside diameter became smaller, Eng-A promptly bended the tube which can prevent Axis-A&B from expanding and can get approximate circle cross section products.

And researchers also interviewed the Eng-B. Eng-B mainly focused on bending procedure and hardly cared about the collect thickness of tube wall which is very different from Eng-A’s operation.

This interview, among engineers, clear differences were found in the knowledge of each process.

7 Conclusion

In order to perform bending with stable quality is to understand that the glass tube is changed by bending motion, and it is important to control the heating of the glass tube. Superficially, it may be seem that the main difference between two engineers is that the Eng-A just conduct one bending movement to process required effect. But it is just suitable for the quartz glass tubes which were used in this study. It’s possible that Eng-A conduct more bending-motion for other different size of tube. In this case also, Eng-A told that the most important factor should be concerned is the status of tube during heated and processed. Meanwhile, ‘collecting the thickness’ is of great concern during bending process, which is useful for determining the process method for specific type of tube and improving product quality.

In this study, the differences in the working process and the product quality between engineers with different years of experience during the fire-process of quartz glass material were analyzed.

The result shows that there was a clear difference in the product quality based on skill maturity.

Eng-A can use ‘collecting the thickness’ method to control the status of quartz glass tube and expend much less time than Eng-B, which not only improves product quality but also enhance productivity.

In future research, the movement of operator will be as experimental subject with combining the results of this study and the experiment method will be further discussed to improve product quality and the level of production.

References

Cibiel, G.: Ultra stable oscillators dedicated for space applications: oscillator and quartz material behaviors vs radiation. In: 2006 IEEE International Frequency Control Symposium and Exposition. IEEE (2006)

He, R.: Research on the forming technique and surface treatment process of quartz glass bulbs for arc tubes. In: 2011 Second International Conference on Mechanic Automation and Control Engineering (MACE). IEEE (2011)

Cobbold, G.W.N., Underdown, A.E.: Some practical applications of quartz resonators. Inst. Electr. Eng.-Proc. Wirel. Sect. Inst. 3(9), 151–162 (1928)

Kaplan, W., Elderstig, H., Veider, C.: A novel fabrication method of capillary tubes on quartz for chemical analysis applications. In: 1994 Proceedings of IEEE Workshop on Micro Electro Mechanical Systems, MEMS 1994. IEEE (1994)

Booth, C.F.: The application and use of quartz crystals in telecommunications. J. Inst. Electr. Eng.-Part III: Commun. Eng. 88(2), 97–128 (1941)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this paper

Cite this paper

Suda, M., Takahashi, T., Hattori, A., Goto, A., Hamada, H. (2016). Process Analysis of Expert and Non-expert Engineers in Quartz Glass Bending Process. In: Duffy, V. (eds) Digital Human Modeling: Applications in Health, Safety, Ergonomics and Risk Management. DHM 2016. Lecture Notes in Computer Science(), vol 9745. Springer, Cham. https://doi.org/10.1007/978-3-319-40247-5_20

Download citation

DOI: https://doi.org/10.1007/978-3-319-40247-5_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-40246-8

Online ISBN: 978-3-319-40247-5

eBook Packages: Computer ScienceComputer Science (R0)