Abstract

Reconfigurable manufacturing has been widely labelled the manufacturing paradigm of the future, due to its ability to rapidly and cost-efficiently respond to changing market conditions. Manufacturing reconfigurability can be dealt with at various levels of the factory, and includes multiple design and operational issues related to both physical and logical reconfigurations. The purpose of this paper is to review state-of-the-art literature on reconfigurable manufacturing and provide an overview of the current body of research, by assessing which structuring levels of the factory and corresponding research issues that are dealt with. Conclusively, currently unexplored areas and interesting issues that could be addressed in future research are identified.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Reconfigurable manufacturing

- Reconfigurability

- Factory structuring levels

- Literature classification

- Literature review

1 Introduction

Today’s manufacturing companies face challenges that have followed globalization, e.g. the fragmentation and change of customer demands, increased need for customized products, fast developing technologies, and focus on environmental sustainability [30]. In order to remain competitive, manufacturing companies need to develop the ability to design and operate manufacturing systems that can be continuously upgraded and changed, instead of being dedicated and optimized for one specific product model and delivery situation [22, 23]. For that reason, the reconfigurable manufacturing concept has been widely recognized as the manufacturing paradigm of the future [35].

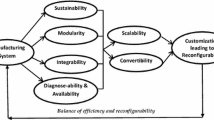

The reconfigurable manufacturing concept was initially introduced in the 90’s as an extension of flexible manufacturing, with the goal of combining the efficiency of dedicated manufacturing lines and the functional flexibility of the flexible systems [19]. In this way, the traditional trade-off between efficiency and flexibility is reduced and the issues of flexible manufacturing systems in regards to excess flexibility, low production rate, and low return on investments are avoided [22, 35]. Reconfigurability can generally be defined as the ability to repeatedly change capacity and functionality in a cost-efficient way, in order to meet different demand situations in terms of variation in volume as well as in product characteristics [23]. This ability to change can be achieved at different levels, e.g. on system and machine level, and involves multiple aspects of manufacturing enterprises [18]. The purpose of this paper is to review and classify state-of-the-art literature related to the reconfigurable manufacturing paradigm, examine which structuring levels of the factory that are most dealt with, and identify research issues at each level. Moreover, the classification of literature provides the foundation for identifying unexplored areas that could be relevant for future research.

The paper is structured as follows: Sect. 2 presents the methodology applied to collect relevant literature for the review, Sect. 3 briefly introduces reconfigurable manufacturing and the classification framework, while Sect. 4 presents the classification of literature in accordance with the related manufacturing levels. Conclusively, the issues discussed at each level are outlined and viable future research directions are proposed.

2 Literature Review Methodology

The objective of this literature review is to identify major tendencies in current literature on reconfigurable manufacturing, by conducting the following steps: retrieval, exclusion, and classification [14]. In order to identify relevant literature for the review, a rather broad search strategy was applied using Web of Science as the primary search database. The search consists of a topic search with two blocks being “reconfigurable” and “manufacturing” or “production”. The time frame was set from 1990 to present day and only papers in English were included. The search was limited to “science technology” as the research domain and the following research areas were included: “operations research”, “engineering”, and “management science”. In addition to the search, experts in the domain were identified through citation records and reference lists, which provided an additional number of papers to the review. In total, approximately 450 papers were initially retrieved, from which only 152 papers were included in the review. The exclusion of papers was based on a qualitative assessment of the following criteria: (a) the reconfigurable manufacturing paradigm should be the central theme or motivation for the research (b) the reconfigurability characteristics (customization, integrability, modularity, convertibility, scalability, diagnosability) are either implicitly or explicitly dealt with in the research.

In order to analyze the selected papers, a classification according six levels of reconfigurability was carried out. These levels correspond to the six structuring levels of factories as proposed by Wiendahl et al. [31]. The papers were classified when a primary level in relation to the research was directly stated or could be identified. Moreover, some of the included papers deal with several levels and are therefore classified in accordance with up to three levels. In total, 24 of the papers were identified as covering multiple levels, where 20 covered two levels and 4 covered three levels. For conciseness, only a minor part of the reviewed papers are included in the reference list of this paper. However, the full research protocol can be provided by inquiry to the authors. In the following section, the concept of reconfigurable manufacturing and the classification framework are presented.

3 Reconfigurability Definition, Characteristics, and Classification Framework

Manufacturing reconfigurability can generally be defined as the ability to repeatedly change capacity and functionality in a cost-efficient way, in order to meet different market situations. This ability to reconfigure efficiently is achieved through the following reconfigurability characteristics: customization, convertibility, scalability, modularity, integrability, and diagnosability [18]. In essence, these characteristics make systems, machines, and enterprises changeable in both capacity and functionality, which is the reason why reconfigurable manufacturing is widely labelled the manufacturing paradigm of the future [35]. Moreover, the reconfigurability characteristics should inherently be embedded in every aspect of reconfigurable manufacturing, e.g. in the planning and control, in the design of the system, and in the machine design in order to realize manufacturing reconfigurability [17]. These different aspects of the reconfigurations are traditionally divided in physical and logical types, where physical reconfigurations involve hard changes in equipment and arrangement of machines and logical reconfigurations involve soft changes such as re-routing and re-planning [31]. Evidently, realizing the vision of reconfigurable manufacturing, in terms of having the exact capacity and functionality needed when needed, involves multiple issues and ability to reconfigure at multiple levels [18]. For instance, system level issues could be the arrangement of physical modules, while on lower levels individual pieces or groups of equipment and machines could be considered [19]. However, reaping the full benefits of reconfigurable manufacturing is widely regarded as a paradigm shift, which inevitably changes at levels beyond what is covered on station and system level [15, 18].

Principally six structuring levels of a manufacturing company can be defined, which are differentiated both from a process and a space perspective and from a product level focus [31, 32]:

-

Network: the highest structuring level, which comprises the network of sites that the manufacturing company is embedded in.

-

Factory: the level of the plant, covering the building and its infrastructure.

-

Segment: the level above the system, which contains all activities involved in manufacturing and making ship-ready products.

-

System: the level containing interlinked cells used for manufacturing variants of a part or a product family.

-

Cell: the level covering a subsystem of the system, containing groups of work stations and material handling that perform most activities to finish a part.

-

Workstation: the lowest structuring level, containing single workstations and machines that add a feature to a work piece.

These structuring levels have in literature been applied to define different classes of changeability in relation to the concept of changeable manufacturing, which is an umbrella term covering all aspects of a manufacturing enterprise that allow for rapid and cost-efficient change in accordance with the environment [12]. In relation to this, reconfigurability is interpreted and defined as a term limited to levels below factory level, whereas agility and transformability are defined as changeability classes for upper levels. However, these changeability classes are not widely used in literature and there is no evidence of consistent use of the terms in relation to the stated levels. The concept of enterprise reconfigurability, which covers the ability of enterprises to adjust the network and form strategic alliances continuously is an example of reconfigurability applied to levels above the segment [6, 18]. Moreover, as the focus of this paper is to investigate current state-of-the-art research on reconfigurable manufacturing, and not research related to all aspects of changeable manufacturing, it is still a pertinent subject to investigate the structuring levels of the manufacturing company in relation to reconfigurability. In other words, the focus of this paper is not on how changeability can be achieved at each level of the factory, but rather how different aspects of reconfigurable manufacturing impact and are dealt with at each level of the factory. This is an interesting research subject, as realizing the benefits of reconfigurable manufacturing as a new production paradigm requires that reconfigurability issues are addressed at various levels of the factory [18]. Thus, it is highly relevant to provide an overview of current research and identify which levels that are addressed widely and more importantly if there are levels that are left comparatively unexplored.

4 Classification of Literature

From the literature retrieval and exclusion process, a total of 152 papers were included in the review and classified in relation to the six structuring levels of the factory. In Table 1, the absolute and relative amount of papers at each level are outlined. Additionally, dominant research issues at each level are indicated and examples of seminal contributions are included as references.

From this classification of literature, it is indicated that research on reconfigurable manufacturing primarily is related to the system and workstation level, with more than two thirds covering the system level and a third covering reconfigurations on work-station level. The system reconfiguration issues are mainly related to logical of soft types of reconfigurations, such as optimal reconfiguration selection or process planning. In contrary, the work-station level deals heavily with physical and hard types of reconfigurations in terms of designing reconfigurable machines. This distinction in research focus across levels supports the proposition by Bi et al. [5], stating that reconfigurability at lower organizational levels mainly is achieved through hardware changes, while reconfigurability at higher levels is achieved through software and control changes.

Another notable result from the classification is the differences between system and cell level, in terms of both research amount and the related issues. At cell-level, a main research issue is how to develop reconfigurable control systems that can control a process that is continuously and physically reconfigured. In many cases, these cell level papers on control systems are also related to the system level, as they demonstrate concepts or methods that are developed ideally for the entire system, but validated at the cell level, e.g. as by Valente and Carpanzano [29]. This logic could also be applied to the issue of developing technologies for seamless integration of machines and devices in the system or cell. A logical conclusion from this is that cell-level papers deal with research issues that are significantly complex and therefore calls for a more narrow scope than the entire system, even though they eventually and in practice must be applied to the entire manufacturing system.

Furthermore, it should be noted, that in the classification, factory and segment level papers are considered as one group. The reason for this is two-fold. First of all, the factory and segment level may not be easily distinguished, as the distinction depends heavily on the relative size of the factory referred to. Additionally, as only few of the reviewed papers cover research on these two levels, it was considered reasonable to regard them as one level. In the following section, the distribution of papers at each of the levels and potential research gaps are discussed, providing the foundation for indicating relevant future research directions.

5 Discussion

Only a minor part of the reviewed papers covers research related to higher structuring levels of the factory, which is the plant and the network level. On network level, the few examples of reconfigurability deal primarily with how to achieve agility through continuously reconfiguring the supply chain when a new business opportunity arises. However, this research area lacks an explicit connection to manufacturing reconfigurability and coverage of how changes on shop floor are related to the supply chain structure. Therefore, this literature review indicates a gap in research on supply chain management issues in relation to operating a reconfigurable manufacturing system. Moreover, there is limited indication of research on lower levels acknowledging that reconfigurability on system, cell, or station-level has consequences on activities that happen outside the boundaries of the firm. However, in order to take full advantage of a reconfigurable system, reduce the time for new product introductions, increase product varieties, and quickly adapt to changing market conditions, it appears to be important also to consider the supply chain. Some indications of potential supply chain considerations are provided in current literature, e.g. selecting suppliers based on their type of manufacturing system [9] and issues related to buying or renting machine or tool modules required in a new configuration or selling those that have become obsolete with the reconfiguration [34]. In accordance with this, Chaube et al. [9] indicate that the lack of research on supply chain issues is one of the main problems in the implementation of reconfigurable manufacturing.

A similar gap exists at the factory-level, where research is also rather limited compared to lower levels. One of the primary focuses at this level is the transformable factory, which is a factory that is adaptable in its production and logistical structures, in buildings, and in organizational structures [32]. However, contributions in this area are rather conceptual, which leaves many interesting areas unaddressed, as operating a reconfigurable manufacturing system inevitably has numerous implications and requirements at factory level, in terms of logistical planning, layout planning, and in terms of organizational work structures.

6 Conclusion

Reconfigurable manufacturing has been widely labelled the manufacturing concept of the future, as manufacturers today need to respond quickly and efficiently to changing market conditions. Reconfigurability in manufacturing has been on the research agenda for the last two decades, and covers many different research issues. This paper has investigated which structuring levels of the factory that are currently most dealt with through a classification of literature. Moreover, research issues at each level have been identified, and the findings of the paper support the notion of lower levels primarily discussing physical reconfiguration, while higher levels mostly deal with logical reconfigurations. Additionally, one of the main findings of the classification is that a considerable share of current research is devoted to investigating the lower levels of reconfigurability, which is the system, cell, and station. However, it should be emphasized that doing reconfigurations on shop-floor has numerous implications for the entire factory in terms of its layout, structure, and logistical setup, but also outside the boundaries of the firm. In particular, supply chain management issues related to manufacturing reconfigurations should be a subject to future research, as it is currently left rather unexplored. Therefore, it is necessary that research in the future focuses broadly on the higher level requirements and issues that follow directly from operating a reconfigurable manufacturing system, in order to fully realize its potential in industry as the new manufacturing paradigm.

References

Abdi, M.R., Labib, A.W.: A design strategy for reconfigurable manufacturing systems (RMSs) using analytical hierarchical process (AHP): a case study. Int. J. Prod. Res. 41, 2273–2299 (2003)

Argoneto, P., Bruccoleri, M., Nigro, G.L., et al.: High level planning of reconfigurable enterprises: a game theoretic approach. CIRP Ann. Manuf. Technol. 55, 509–512 (2006)

Azab, A., ElMaraghy, H.: Sequential process planning: a hybrid optimal macro-level approach. J. Manuf. Syst. 26, 147–160 (2007)

Benjaafar, S., Heragu, S.S., Irani, S.A.: Next generation factory layouts: research challenges and recent progress. Interfaces 32, 58–76 (2002)

Bi, Z., Lang, S.Y., Verner, M., et al.: Development of reconfigurable machines. Int. J. Adv. Manuf. Technol. 39, 1227–1251 (2008)

Bruccoleri, M., Nigro, G.L., Perrone, G., et al.: Production planning in reconfigurable enterprises and reconfigurable production systems. CIRP Ann. Manuf. Technol. 54, 433–436 (2005)

Bruccoleri, M., Renna, P., Perrone, G.: Reconfiguration: a key to handle exceptions and performance deteriorations in manufacturing operations. Int. J. Prod. Res. 43, 4125–4145 (2005)

Chan, K., Benhabib, B., Dai, M.: A reconfigurable fixturing system for robotic assembly. J. Manuf. Syst. 9, 206–221 (1990)

Chaube, A., Benyoucef, L., Tiwari, M.K.: An adapted NSGA-2 algorithm based dynamic process plan generation for a reconfigurable manufacturing system. J. Intell. Manuf. 23, 1141–1155 (2012)

Chen, H., Fuhlbrigge, T., Zhang, G., et al.: “Plug and produce” functions for an easily reconfigurable robotic assembly cell. Assembly Autom. 27, 253–260 (2007)

Deif, A.M., ElMaraghy, H.A.: Assessing capacity scalability policies in RMS using system dynamics. Int. J. Flex. Manuf. Syst. 19, 128–150 (2007)

ElMaraghy, H.A., Wiendahl, H.P.: Changeability - an introduction. In: ElMaraghy, H.A. (ed.) Changeable and Reconfigurable Manufacturing Systems, pp. 3–24. Springer, London (2009)

Gyulai, D., Kádár, B., Kovács, A., et al.: Capacity management for assembly systems with dedicated and reconfigurable resources. CIRP Ann. Manuf. Technol. 63, 457–460 (2014)

Hart, C.: Doing a Literature Review: Releasing the Social Science Research Imagination. Sage Publications, Thousand Oaks (1998)

Heisel, U., Meitzner, M.: Progress in reconfigurable manufacturing systems. In: Dashcenko, A.I. (ed.) Reconfigurable Manufacturing Systems and Transformable Factories, pp. 47–62. Springer, Heidelberg (2006)

Katz, R.: Design principles of reconfigurable machines. Int. J. Adv. Manuf. Technol. 34, 430–439 (2007)

Koren, Y.: General RMS characteristics. Comparison with dedicated and flexible systems. In: ElMaraghy, H.A. (ed.) Reconfigurable Manufacturing Systems and Transformable Factories, pp. 27–45. Springer, Heidelberg (2006)

Koren, Y.: The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems. Wiley, New York (2010)

Koren, Y., Heisel, U., Jovane, F., et al.: Reconfigurable manufacturing systems. CIRP Ann. Manuf. Technol. 48, 527–540 (1999)

Liu, W., Liang, M.: Multi-objective design optimization of reconfigurable machine tools: a modified fuzzy-chebyshev programming approach. Int. J. Prod. Res. 46, 1587–1618 (2008)

Maler-Speredelozzi, V., Koren, Y., Hu, S.: Convertibility measures for manufacturing systems. CIRP Ann. Manuf. Technol. 52, 367–370 (2003)

Mehrabi, M.G., Ulsoy, A.G., Koren, Y., et al.: Trends and perspectives in flexible and reconfigurable manufacturing systems. J. Intell. Manuf. 13, 135–146 (2002)

Mehrabi, M.G., Ulsoy, A.G., Koren, Y.: Reconfigurable manufacturing systems: key to future manufacturing. J. Intell. Manuf. 11, 403–419 (2000)

Padayachee, J., Bright, G.: The design of reconfigurable assembly stations for high variety and mass customisation manufacturing. S. Afr. J. Ind. Eng. 24, 43–57 (2013)

Ribeiro, L., Barata, J., Colombo, A.: Supporting agile supply chains using a service-oriented shop floor. Eng. Appl. Artif. Intell. 22, 950–960 (2009)

Rösiö, C., Säfsten, K.: Reconfigurable production system design–theoretical and practical challenges. J. Manuf. Technol. Manage. 24, 998–1018 (2013)

Singh, R., Khilwani, N., Tiwari, M.: Justification for the selection of a reconfigurable manufacturing system: a fuzzy analytical hierarchy based approach. Int. J. Prod. Res. 45, 3165–3190 (2007)

Spicer, P., Yip-Hoi, D., Koren, Y.: Scalable reconfigurable equipment design principles. Int. J. Prod. Res. 43, 4839–4852 (2005)

Valente, A., Carpanzano, E.: Development of multi-level adaptive control and scheduling solutions for shop-floor automation in reconfigurable manufacturing systems. CIRP Ann. Manuf. Technol. 60, 449–452 (2011)

Westkämper, E.: New trends in production. In: Dashcenko, A.I. (ed.) Reconfigurable Manufacturing Systems and Transformable Factories, pp. 15–26. Springer, Heidelberg (2006)

Wiendahl, H., ElMaraghy, H.A., Nyhuis, P., et al.: Changeable manufacturing-classification, design and operation. CIRP Ann. Manuf. Technol. 56, 783–809 (2007)

Wiendahl, H., Hernández, R.: The transformable factory–strategies, methods and examples. In: Dashcenko, A.I. (ed.) Reconfigurable Manufacturing Systems and Transformable Factories, pp. 383–393. Springer, Heildelberg (2006)

Xiaobo, Z., Jiancai, W., Zhenbi, L.: A stochastic model of a reconfigurable manufacturing system part 1: a framework. Int. J. Prod. Res. 38, 2273–2285 (2000)

Youssef, A.M., ElMaraghy, H.A.: Assessment of manufacturing systems reconfiguration smoothness. Int. J. Adv. Manuf. Technol. 30, 174–193 (2006)

Zhang, G., Liu, R., Gong, L., et al.: An analytical comparison on cost and performance among DMS, AMS, FMS and RMS. In: Dashcenko, A.I. (ed.) Reconfigurable Manufacturing Systems and Transformable Factories, pp. 659–673. Springer, Heidelberg (2006)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 IFIP International Federation for Information Processing

About this paper

Cite this paper

Andersen, AL., Brunoe, T.D., Nielsen, K. (2015). Reconfigurable Manufacturing on Multiple Levels: Literature Review and Research Directions. In: Umeda, S., Nakano, M., Mizuyama, H., Hibino, N., Kiritsis, D., von Cieminski, G. (eds) Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth. APMS 2015. IFIP Advances in Information and Communication Technology, vol 459. Springer, Cham. https://doi.org/10.1007/978-3-319-22756-6_33

Download citation

DOI: https://doi.org/10.1007/978-3-319-22756-6_33

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22755-9

Online ISBN: 978-3-319-22756-6

eBook Packages: Computer ScienceComputer Science (R0)