Abstract

ReservoirBench is an interactive workbench for educational geological science and engineering tasks. It is designed to facilitate education of novice audiences to teach them basic concepts of reservoir modeling and simulation workflow. Traditional training using lectures and software practice can lead to information overload, and retainability is questionable. As an alternative, we propose a physical workbench that is coupled with digital augmentation for the purpose of learning. We take advantage of the crucial role that spatiality and 3D representations play in petroleum reservoir modeling and allow basic domain concepts to be introduced and explored in a tangible and experiential manner. We describe the design of our prototype and reflect on the findings from our preliminary design critique.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The domain of petroleum engineering aims at studying the processes involved in the exploration, production and extraction of oil and gas [8]. Introduction of domain concepts via presentations and software tutorials can be difficult to grasp for novice audiences such as first year geology undergraduates or non-domain experts who join the industry (e.g. computer scientists). Generic slideshows can cause information overload, and content retainability is questionable [16, 17]. On the other hand, simulation software packages such as PetrelTM [3] are designed for the expert user. Since the goal is to become familiar with fundamental concepts and general modeling workflows (engineering data integration, layer interpretation from seismic data, well modeling, reservoir simulation and identifying challenging cost-benefit scenarios for well drilling), more suitable and interactive training methods are called for. The question then becomes, “How can interactive interfaces be used to scaffold comprehension for novice users?”

Modeling the petroleum reservoirs in 3D requires having the knowledge of spatial configurations, structures and properties that are central to efficient data integration and reservoir characterization. This was motivated before via cardboard box models used to demonstrate the functionality of PetrelTM, a commercial oil-and-gas software package [2]. Interactive physical interfaces can help in automating this 3D spatial approach and can be designed to map interactions to varying visualizations to enhance the learning process [11]. We propose the use of a physical interactive workbench coupled with digital augmentation for teaching the basics of reservoir modeling workflows (Figs. 1 and 2). ReservoirBench is the first experiential learning reservoir engineering tangible user interface (TUI) for novice users and the uniqueness emerges from the application specific tasks.

2 Related Work

Physical and tangible user interfaces have been previously introduced for the purpose of teaching [9, 11, 14] and have contributed to develop ways to enhance learning [13, 21]. It has been noted that in situations where perception and cognition can be coupled [5], using physical materials in a learning task can change the nature of awareness gained relative to that gained through interacting with virtual materials [12].

Our workbench design supports experiential learning which encourages one to generate their own ideas about a phenomena while learning and prepares the individual for future learning [6]. More detailed knowledge could be developed as part of actual reservoir modeling tasks where the limitations of current software impede easiness and efficiency of implementing the various modeling and design scenarios. Our workbench can also be looked through the theoretical lens of boundary object’s [18]. The structure of the interface is common enough to be recognized by the domain of oil and gas in general, but each sub-domain (i.e. geologist, reservoir engineer) can use it as a medium for different task explorations.

Within the realm of geology and reservoir engineering, TUI’s [7, 10, 15], tabletop interfaces [19, 20] and a web-based interface [4] have been previously introduced. However, the focus in these instances of research has mainly been on data exploration. For instance, Snakey [10] is a TUI designed exclusively for expert users engaged in the particular task of well design in reservoir engineering. It is not an educational toolkit and does not attempt to address the breadth of essential reservoir modeling concepts that ReservoirBench is addressing.

3 ReservoirBench: Design and Implementation

3.1 Physical Interface

The physical interface is a simplified representation of an underground reservoir (Fig. 1). It consists of a wood frame structure (roughly 18 inch (l) × 18 inch (w)) with three slots on each of the vertical poles (Fig. 1a). The two vertical poles serve the dual purpose of being support structures as well as being representations of two already drilled oil wells used for seismic well-tie [8]. The top of the frame is sealed with a plane that represents the ground level. Three orthogonal planes, symbolic of seismic planes can be inserted into the empty slots using different configurations as seen in the Fig. 1a. The seismic planes define the boundaries between the different earth layers. Physical oil well trajectories can be inserted between the planes using either the 3Doodler (handheld fabrication tool [1]) or pipe cleaners (Fig. 1b).

The design rationale behind different configurations for the seismic planes comes from the fact that (in reality) the low resolution seismic volumes can impose a large uncertainty in defining the hydrocarbon producing layers. However, for the purpose of learning some options in terms of placements of seismic planes are sufficient to explore the concept of stratigraphic uncertainty in layers’ thicknesses and their effects on calculation of volumetrics (e.g. initial hydrocarbon in place), reservoir performance and drilling plan of new infill wells for production optimization.

On the other hand, since the well trajectories are relatively more flexible in terms of design (i.e. can have configurations such as horizontal, vertical and multi-lateral [8]), we choose to test two different material options - the 3DoodlerTM and pipe cleaners. One of the fundamental constraints to input well trajectories is that the material should have the ability to retain shape and yet be malleable. Pipe cleaners are advantageous as they are flexible and afford for molding, but are limited as they do not afford the property to be easily molded back to their original state. In contrast, 3DoodleTM is a step forward towards supporting free form sketching of 3D objects and thus, can better support quick iterative design explorations. However, it is important to note that accurate design of horizontal wells is rather difficult using the 3DoodlerTM due to gravity effect. In contrast to Snakey’s [10] rigid and difficult to manipulate interface that is built from camera tripods, both the 3Doodler and the pipe cleaner afford further flexibility for free-form and iterative well design.

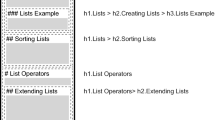

3.2 Digital Interface

The digital interface represents the visual feedback for the physical interactions (Fig. 2). The use of a monitor to display the visualizations was done keeping in mind the availabilities in a regular office setting. Placing the monitor above the physical interface was considered to be a better alternative to a side-by-side setup and can also work for demonstration purposes. In our current prototype the physical source object (Fig. 2a) can be digitally augmented in the four ways explained below. The visualizations are simplified reservoir modeling visualizations that professionals use during the regular workflow of examining seismic planes, gridding and well trajectories.

Figure 2b: shows the visualization of the geological layers of the earth mapped to the tracked physical seismic planes configuration that can be (re)arranged by the user. We use a Kinect to track the positions of the colored markers placed on the edge of the physical planes (Fig. 2a). The positions of the markers extracted from the Kinect image are converted into 3D coordinates to render the virtual seismic planes. A bounding box encompassing the virtual planes is computed and drawn to represent an approximate reservoir model. The purpose of this visualization is to provide contextual information regarding how a reservoir looks beneath the surface of the earth and helps identify in which layer oil is currently present and what is in the surrounding layers (e.g. aquifer, cap rock etc.).

Figure 2c: shows the visualization of the well trajectories input physically by the user. To reconstruct the virtual well we first compute the difference between the initial source image (before the well was inserted) and the current frame image (after the well was inserted) from the Kinect 2.0. Zhang-Suen thinning algorithm [22] is applied to the segmented image to extract the well trajectory skeleton. The skeleton and the depth image are then used in the calculations for 3D well reconstruction. The Kinect is placed at an angle as seen in Fig. 1 to capture maximum information. Our current prototype is limited by the use of a single Kinect camera and thus, occlusions cannot be resolved. However, since accuracy was not our primary concern when introducing basic concepts, we think this is a reasonable limitation. The well visualization is also coupled with a graph that shows the cost for drilling the infill well. From the vector direction of the well skeleton, the program automatically classifies the wells as either vertical (low cost) or horizontal wells (high cost), and the graph is updated to show the corresponding cost for drilling.

Figure 2d: shows the visualization of the gridded simulation model. The rendered grid is adapted to align according to the top and bottom of the seismic plane orientation allowing the viewer to learn about the variability in vertical thickness in each cell layer. The resolution of the grid can be changed using a physical slider. The purpose for changing grid sizes is to allow the user to get a sense of how discretization is performed in real modeling cases and understand its effect on the time needed for completing a flow simulation run (which can be a very time consuming task based on the resolution of the grid). Thus, when the user interacts with the slider a graph showing the amount of time required for simulation is displayed.

Figure 2e: shows the intersection between the grid cells and the created well trajectories. In terms of learning, observing such intersections helps: (a) identify the cells with interesting heterogeneities, which might require further treatments in terms of nested local grid refinement and (b) identify the most and least contributing cells to the oil production rate.

3.3 Workflow Example and Presented Concepts

Figures 1 and 2 show the workflow of a user interacting with the ReservoirBench. The workflow is also a pointer to the various concepts that one can learn and explore. The typical workflow starts with positioning the interpreted (Concept #1) seismic planes configuration (obtained in actual workflow from 3D seismic data) [8] (Fig. 1a). Once the seismic configuration is in place (Fig. 1a), the user can explore the automatically generated (Concept #2) geological layers (i.e. between the seismic planes, Fig. 2b) and plan to (Concept #3) create a suitable new well trajectory to extract more oil from the reservoir. Figure 1b shows a user creating a new well trajectory using the 3DoodlerTM. Once the well is in position, the well is virtually reconstructed (Fig. 2c). The well trajectory can be positioned at any depth position of the plane. In practice, the well should be drilled starting from the ground surface, in the current prototype the user only needs to position the well in the target layer in which oil is found. This is also common practice in reservoir modeling software programs. The connection from the reservoir top to the ground surface is automatically computed by our program. Depending on the well created by the user, the program presents a graph of the (Concept #4) drilling cost of such a well (Fig. 2c). Finally, the user can (Concept #5) grid the reservoir model for simulation and understand the impact of the grid resolution on the (Concept #6) time for the reservoir simulation runs (Fig. 2d).

4 Preliminary Design Critique

To evaluate the limitations and advantages of the different components of our interface we conducted a preliminary design critique session with a domain and a non-domain (computer science graduate student) participant. The domain expert, a post-doctoral fellow in reservoir modeling with several years of experience in geoscience research and reservoir engineering, was involved in the iterative design and development of our interface. With the obvious limitations of our preliminary design critique (small number of participants, possible biases), it did provide interesting design reflection on ReservoirBench, including those of an expert reservoir engineer with considerable experience in this design space. Following we believe the insight we share below, while limited in scope, is still valid. We took a hands-on approach to design critique, asking both the participants to complete the following tasks: (a) arranging the seismic planes to the experimenter provided configurations, (b) creating a vertical and/or horizontal well to extract oil and (c) choosing the appropriate simulation model grid size and observe the costs and simulation time. At the end of the tasks we gathered qualitative feedback.

Domain Participant:

In the opinion of the domain expert ReservoirBench can be useful for educating novices’ about conceptual ideas, for example, what is a seismic plane? And, where is oil? He envisions that with increasing the complexity of the system and by combining the interface with an actual simulation program, the current interface can be used by the domain experts for testing out complex tasks i.e. reservoir characterization, economics calculations and well test design. ReservoirBench could also be used to design and/or to fine tune a 3D digital model and to explore various production scenarios for well placement. The domain expert found automatic reconstruction of physical well trajectories to be a useful feature for quick design iterations. Although the 3DoodlerTM is a flexible fabrication tool, it was difficult to use and found to be distracting due to its current limitations (speed of use, fat pen, gravity etc.) Therefore, the domain expert preferred the pipe cleaners, especially for designing horizontal wells. One of the noted limitations for the pipe cleaners was their length. Since the performance of a horizontal well depends on factors i.e. length and location within the layer, this was considered to be an important feature to keep in mind while choosing the right material.

Non-domain Participant:

In addition to the hands-on tasks, the non-domain participant also answered the following eight questions: (1) what is a reservoir? (2) What is between the seismic planes? (3) What is a reservoir model? (4) What is the purpose of a reservoir model? (5) Which processes are involved in extracting oil? (6) When gridding the reservoir model, when do you think a low resolution grid (less number of cells) could be beneficial? (7) Similarly, when do you think a high resolution grid (more number of cells) could be beneficial? And finally, (8) rationalize the well trajectories you created in the well design task. The collected responses were all valid in terms of expected keywords (determined by domain-expert), pointing towards a positive outcome in terms of learning. From the discussions we learnt that lack of both, feedback during the tasks and prior knowledge, the participant felt less confident in answering the questions. The participant also mentioned that compared to the definition type questions (e.g. questions 1 and 2), she found the interface to be quite useful for answering task related questions (question 8). Beyond learnability, the participant found the interface to be fun, enjoyable and engaging. She mentioned, “It was encouraging of curiosity, and made me want to learn more things. It was satisfying as I felt like it was doing something”.

5 Discussion

Role of Spatiality and 3D representations:

Spatiality and 3D representations play a crucial role in reservoir engineering. The benefit of having an associative and spatial system can help externalize traditional digital representations and present a physical view that people are familiar with [11] and is fundamental to geological entities [10]. Having working knowledge of oil and gas software tools the domain expert mentioned that practical learning with commercial software alone is rather difficult, specifically for non-domain audiences, since the software is designed for experts and not novices. Within this context, in the opinion of the domain expert our hybrid approach (physical-digital coupling) can be useful for training Novice users and arguably also be useful for domain experts to evaluate design choices for well placement tasks.

Control and Representation:

Due to the meticulous nature of tasks conducted by reservoir engineers, interfaces such as ours will be limited in terms of the level of control that can be achieved. As mentioned by both the domain and non-domain participants’, although the 3Doodler was a flexible fabrication tool for design iterations, it was difficult to use and found to be distracting due to the limitations of the current 3Doodler (speed of use, fat pen, gravity etc.). It was found to be lacking in precision and accuracy. Scaling is also a challenge. While part of the scaling issue can be mitigated by the use of digital representations, we need to be careful in our design considerations to ensure that the level of physical-digital coupling is not reduced to the point of creating disconnects in interaction behavior (a noted limitation of Snakey [10]). Alternatively, an advantage of interfaces such as ours is that the low-cost prototype production will allow users to quickly modify the design of the system. Readily available physical mediums can be added as interaction components to create representations that are meaningful to the users and programmatically coded as manipulatives.

Interactivity:

Within ReservoirBench’s context, externalizing geological concepts into easy to grasp physical representations presents a smart interaction alternative to the orthodox approach in which novice users are introduced to the domain (e.g. presentations and textbooks). The potential of systems such as ours lies in their ability to allow people to create and manipulate objects to support hands on learning. It can also function as a boundary object during interdisciplinary interactions. From a design perspective, ReservoirBench can be used not just for the purpose of learning the fundamental concepts but also in other design process such as designing rough 3D reservoir models. Active hands-on learning can also make the experience enjoyable and engaging as mentioned by the non-domain participant.

6 Conclusion and Future Work

We presented ReservoirBench, an interactive and educational TUI that facilitates learning about reservoir modeling workflow. Our preliminary critique highlights the usefulness of such systems for both learning and exploring reservoir modeling workflows. Efforts are underway to further improve our prototype to better facilitate instructional and smarter interactions. The design critiques point at promising benefits for such interfaces, but in future we will need to compare and contrast the ReservoirBench approach to training versus the existing traditional approaches. For long term future work we would like to explore the use of other physical manipulatives such as, grid meshes and fault constraints, to allow novice user’s to gain added understanding on their effect on well planning and simulations. For example, the actual seismic planes combined with the complex 3D structures such as faults and folds can be efficiently used to represent the actual reservoir structures. The strategies to place wells can then be tested more realistically and better gridding strategies could be proposed. It will also be interesting to explore the possibilities of projection mapping and more advanced interaction techniques using 3D printed models.

References

Doodler. http://the3doodler.com/

Boxcut – Phil and Tyson Skit. https://www.youtube.com/watch?v=1_EYUtEp-oo/

Petrel E&P Software. http://www.software.slb.com/products/

Allen, G., Chakraborty, P., Huang, D., Lei, Z., Lewis, J., Li, X., White, C. D., Xu, X., Zhang, C.: A workflow approach to designed reservoir study. In: Proceedings of the 2nd Workshop on Workflows in Support of Large-Scale Science, pp. 75–79 (2007)

Barsalou, L.W.: Grounded Cognition. Ann. Rev. Psychol. 59, 617–645 (2008)

Bransford, J.D., Schwartz, D.L.: Rethinking transfer: a simple proposal with multiple implications. Review of Research in Education 24, 61–100 (1999)

Couture, N., Rivière, G., Reuter, P.: GeoTUI: a tangible user interface for geoscience. In: Proceedings of TEI 2008 (2008)

Dake, L.P.: Fundamentals of Reservoir Engineering. Elsevier, Amsterdam (1983)

Fjeld, M., Voegtli, B.M.: Augmented chemistry: an interactive educational workbench. In: Proceedings of ISMAR 2002, pp. 259–321 (2002)

Harris, J., Young, J., Sultanum, N., Lapides, P., Sharlin, E., Sousa, M.C.: Designing Snakey: a tangible user interface supporting well path planning. In: Campos, P., Graham, N., Jorge, J., Nunes, N., Palanque, P., Winckler, M. (eds.) INTERACT 2011, Part III. LNCS, vol. 6948, pp. 45–53. Springer, Heidelberg (2011)

Ishii, H., Ullmer, B.: Tangible bits: towards seamless interfaces between people, bits and atoms. In: Proceedings of SIGCHI 1997, pp. 232–241 (1997)

Klemmer, S. R., Hartmann, B., Takayama, L.: How bodies matter: fives themes for interaction design. In: Proceedings of DIS 2006 (2006)

Marshall, P.: Do tangible interfaces enhance learning? In: Proceedings of TEI 2007 (2007)

O’Malley, C., Fraser, D.S., et al.: Literature Review in Learning with Tangible Technologies. NESTA Futurelab, Bristol (2004)

Piper, B., Ratti, C., Ishii, H.: Illuminating clay: a 3-D tangible interface for landscape analysis. In: Proceedings of SIGCHI 2002 (2002)

Pugsley, K.E., Clayton, L.H.: Traditional lecture or experiential learning: changing student attitudes. J. Nurs. Educ. 42(11), 520–523 (2003)

Specht, L.B., Sandlin, P.K.: The different effects of experiential learning activities and traditional lecture classes in accounting. Simul. Gaming 22(2), 196–210 (1991)

Star, S.L., Griesemer, J.R.: Institutional ecology, translations’ and boundary objects: amateurs and professionals in Berkeley’s museum of vertebrate zoology. Soc. Stud. Sci. 19(3), 387–420 (1989)

Sultanum, N., Sharlin, E., Sousa M.C., Miranda-Filho, D.N., Eastick, R.: Touching the depths: introducing tabletop interaction to reservoir engineering. In: Proceedings of ITS 2010 (2010)

Tateosian, L., Mitasova, H., et al.: TanGeoMS: tangible geospatial modeling system. IEEE Trans. Vis. Comput. Graph. 16, 1605–1612 (2010)

Ullmer, B., Ishii, H.: Emerging frameworks for tangible user interfaces. IBM Syst. J. 39(3–4), 915–931 (2000)

Zhang, T., Suen, C.Y.: A fast parallel algorithm for thinning digital patterns. ACM Commun. 27(3), 236–239 (1984)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 IFIP International Federation for Information Processing

About this paper

Cite this paper

Somanath, S., Rocha, A., Hamdi, H., Sharlin, E., Sousa, M.C. (2015). ReservoirBench: An Interactive Educational Reservoir Engineering Workbench. In: Abascal, J., Barbosa, S., Fetter, M., Gross, T., Palanque, P., Winckler, M. (eds) Human-Computer Interaction – INTERACT 2015. INTERACT 2015. Lecture Notes in Computer Science(), vol 9296. Springer, Cham. https://doi.org/10.1007/978-3-319-22701-6_26

Download citation

DOI: https://doi.org/10.1007/978-3-319-22701-6_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22700-9

Online ISBN: 978-3-319-22701-6

eBook Packages: Computer ScienceComputer Science (R0)