Abstract

Sequential alarms are alarms triggered in succession by a single root cause in a chemical plant. In general, they occur sequentially with specific time lags within a short period of time and, if they are numerous, they reduce the ability of operators to cope with plant abnormalities because critical alarms can become buried under numerous unimportant alarms. In this paper, we propose a method for identifying sequential alarms hidden in plant operation data by using dot matrix analysis. Dot matrix analysis is one of the sequence alignment methods for identifying similar regions in a pair of DNA or RNA sequences, which may be a consequence of functional, structural, or evolutionary relationships. The proposed method first converts plant operation data recorded in a Distributed Control System (DCS) into a single alarm sequence by putting them in order by alarm occurrence time. Then, similar regions in the alarm sequence are identified by comparing the alarm alignment with itself. Finally, the identified regions, which are assumed to be sequential alarms, are classified into sets of similar sequential alarms in accordance with the similarities between them. The method was applied to simulated plant operation data of an azeotropic distillation column. The results showed that the method is able to correctly identify sequential alarms in plant operation data. Classifying sequential alarms into small numbers of groups with this method effectively reduces unimportant sequential alarms at industrial chemical plants.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Sequential alarms are alarms that occur in succession with specific time lags within a short period of time [1–3]. Sequential alarms are usually caused by poor alarm rationalization [4, 5]. The grouping of correlated sequential alarms in accordance with their degree of similarity helps to identify their occurrences more effectively than by analyzing individual sequential alarms.

The alarm similarity color map [6] is helpful for assessing the performance of alarm systems in terms of effectiveness and reducing the occurrences of sequential alarms. The alarm similarity color map orders alarms in accordance with their degree of Jaccard similarity [7] with other alarms to identify sequential alarms. A Gaussian kernel method [8] was applied to historical alarm data to generate a pseudo-continuous time series to reduce the effect of missed, false, and chattering alarms when visualizing the correlation information from alarms.

Event correlation analysis [9] was proposed to identify sequential alarms in noisy plant operation data. This method uses plant operation data and a cross correlation function to quantify the degree of similarity on the basis of the time lag between two alarms. Sequential alarms are found by grouping correlated alarms and operations in accordance with their degree of similarity. Event correlation analysis was applied to the operation data of an industrial ethylene plant and was able to correctly identify similarities between correlated sequential alarms [10–12]. However, event correlation analysis occasionally failed to detect similarities between two physically related sequential alarms when deletions, substitutions, and/or transpositions occurred in the alarm sequence.

A method for evaluating similarities between sequential alarms by using the normalized Levenshtein distance was proposed [13]. The Levenshtein distance [14, 15] is a string metric for measuring the difference between two sequences defined as the minimum number of edit operations such as insertion, deletion, and substitution of a single character needed to transform one string into another. The Levenshtein distance was applied to the simulation data of an azeotropic distillation column, and the results revealed that the method is able to correctly identify similarities between correlated sequential alarms even when the event correlation analysis failed due to deletions, substitutions, and/or transpositions in the alarm sequence. However, the method is not able to identify sequential alarms hidden in plant operation data.

In this paper, we propose a method that can identify sequential alarms hidden in plant operation data by using dot matrix analysis.

2 Dot Matrix Analysis

Dot matrix analysis [16] is one of the sequence alignment methods for identifying similar regions in DNA or RNA. Figure 1 shows an example of two DNA sequences. Similar regions in DNA or RNA may be a consequence of functional, structural, or evolutionary relationships between the sequences.

In the dot matrix method [17], one sequence S 1 is listed across the bottom of a graph, and the other sequence S 2 is listed down the left side, as illustrated in Fig. 2. Starting with the first character in S 2, the comparison moves across the graph in the first row and places a dot in any column where the character in S 1 is the same. The second character in S 2 is then compared to the entire S 1 sequence, and a dot is placed in row 2 wherever a match occurs. This process is continued until the graph is filled with dots representing all the matches of S 1 characters with S 2 characters. A diagonal row of dots reveals similarity between the two sequences. Dots not on a diagonal row represent random matches that are probably not related to any significant alignment.

The major advantage of the dot matrix analysis for finding sequence alignments is that all possible matches between two sequences are found, leaving the engineers the choice of identifying the most significant matches by examination of the dot matrix for long runs of matches, which appear as diagonals [17].

3 Method for Identifying Sequential Alarms

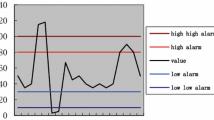

The plant operation data recorded in DCS generally consist of the times alarms occurred and their tag names, as listed in Table 1. The proposed method first converts the plant operation data into a single alarm sequence by putting them in order by alarm occurrence time. Then, the similar regions in the alarm sequences are identified by comparing the alarm alignment with the sequence. Figure 3 shows an example of dot matrix analysis of plant operation data. Finally, the identified similar regions, which are assumed to be sequential alarms, are classified into sets of similar sequential alarms in accordance with the similarities between them.

4 Case Study

The method was applied to the simulation data of the azeotropic distillation column in Fig. 4 [11]. There were a total of 18 alarms in the DCS, which are denoted by E1–E18 in Table 2. Three types of malfunctions (Table 3), low flow rate coolant, low steam pressure, and valve stiction, were randomly caused in the process simulation, which was run using Aspen HYSYS 2.3 (AspenTech, Inc.). A defined operation for each malfunction was carried out after each malfunction occurred, as shown in Table 3. During a process simulation of 15 days, 18 types of alarm and 234 alarm occurrences were recorded in the plant operation data, as shown in Fig. 5.

Process flow diagram of azeotropic distillation column [11]

Figure 6 shows the result of the dot matrix analysis of the plant operation data. A large number of sequential alarms in the plant operation data can be inferred from the multiple diagonal lines. It is possible to identify sequential alarms from Fig. 6. The results revealed that the proposed method is able to correctly identify similar sequential alarms in plant operation data.

5 Conclusion

Dot matrix analysis was applied to the simulated plant operation data of an azeotropic distillation column. The results revealed that the method is able to correctly identify similar sequential alarms in plant operation data. Classifying them into small numbers of groups with this method effectively identifies the sequential alarms at industrial chemical plants.

References

The Engineering Equipment and Material Users’ Association (EEMUA): Alarm Systems A Guide to Design, Management and Procurement Publication No. 191 Edition 2. EEMUA, London (2007)

International Society of Automation (ISA): Management of Alarm Systems for the Process Industries, ANSI/ISA-18.2-2009. ISA, North Carolina (2009)

International Electrotechnical Commission (IEC): IEC 62682 Management of Alarm Systems for the Process Industries. IEC, Geneva (2014)

Hollifield, B.R., Habibi, E.: Alarm Management: Seven Effective Methods for Optimum Performance. ISA, Research Triangle Park (2007)

Rothenberg, D.H.: Alarm Management for Process Control A Best-Practice Guide of Design, Implementation, and Use of Industrial Alarm Systems. Momentum Press, New York (2009)

Kondaveeti, S.R., Izadi, I., Shah, S.L., Balck, T., Chen, T.: Graphical tools for routine assessment of industrial alarm systems. Comput. Chem. Eng. 46, 39–47 (2012)

Lesot, M.J., Rifqi, M., Benhadda, H.: Similarity measures for binary and numerical data: a survey. Int. J. Knowl. Eng. Soft Data Paradigms 1, 63–84 (2009)

Yang, F., Shah, S.L., Xiao, D., Chen, T.: Improved correlation analysis and visualization of industrial alarm data. ISA Trans. 51(4), 499–506 (2012)

Nishiguchi, J., Takai, T.: IPL2&3 performance improvement method for process safety using the event correlation analysis. Comput. Chem. Eng. 34, 2007–2013 (2010)

Higuchi, F., Noda, M., Nishitani, H.: Alarm reduction of ethylene plant using event correlation analysis. Kagaku Kogaku Ronbunshu 36(6), 576−581 (2010) (in Japanese)

Kurata, K., Noda, M., Kikuchi, Y., Hirao, M.: Extension of event correlation analysis for rationalization of plant alarm systems. Kagaku Kogaku Ronbunshu 37, 338−343 (2011) (in Japanese)

Takai, T., Noda, M., Higuchi, F.: Identification of nuisance alarms in operation log data of ethylene plant by event correlation analysis. Kagaku Kogaku Ronbunshu 38 (2), 110−116 (2012) (in Japanese)

Akatsuka, S., Noda, M.: Similarity analysis of sequential alarms in plant operation data by using Levenshtein distance. In: Proceedings of the PSE Asia 2013, Kuala Lumpur (2013)

Levenshtein, V.I.: Binary codes capable of correcting deletions. Insertions Reversals Cybern. Control Theory 10(8), 707–710 (1966)

Yujian, L., Bo, L.: A normalized Levenshtein distance metric. IEEE Trans. Pattern Anal. Mach. Intell. 29(6), 1091–1095 (2007)

Gibbs, A.J., McIntyre, G.A.: The diagram method for comparing sequences. Its use with amino acid and nucleotide sequences. Eur. J. Biochem. 16, 1–11 (1970)

Mount, D.W.: Bioinformatics Sequence and Genome Analysis, 2nd edn. Cold Spring Harbor Laboratory Press, New York (2004)

Acknowledgments

This work was supported by JSPS Kakenhi Grant Number 24560942.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Wang, Z., Noda, M. (2015). Dot Matrix Analysis of Plant Operation Data for Identifying Sequential Alarms Triggered by Single Root Cause. In: Yamamoto, S. (eds) Human Interface and the Management of Information. Information and Knowledge in Context. HIMI 2015. Lecture Notes in Computer Science(), vol 9173. Springer, Cham. https://doi.org/10.1007/978-3-319-20618-9_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-20618-9_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-20617-2

Online ISBN: 978-3-319-20618-9

eBook Packages: Computer ScienceComputer Science (R0)