Abstract

In many practical applications of fatigue loadings with low amplitudes a number of higher load cycles are applied that overcome the threshold of the material yield strength, even if only locally. This circumstance is not taken into account by the classic theory of fatigue at a high number of cycles that assumes elastic states of stress at any point of a loaded body and a limited micro-plasticity at critical points. In the field of high load cycles, damage due to local plasticity is instead the governing phenomenon. Simulation models are developed based on a strain-controlled approach, especially in the cases of complex (i.e. not constant but time-varying) loads amplitudes. This local nonlinear cyclic behavior leads to a damage that occurs for a limited number of cycles \(< 5\times 10 ^ 4\). This numerical limit is conventional, based on experience and therefore subjected to different estimations by different authors. A similar convention emerges in establishing the test conclusion when the first visible crack appears (an event subjected to interpretation).

This is a preview of subscription content, log in via an institution.

Buying options

Tax calculation will be finalised at checkout

Purchases are for personal use only

Learn about institutional subscriptionsNotes

- 1.

Details in A.S.T.M. standardized procedure to determine the fatigue curve in deformation control for lives at low number of cycles, in accordance with \(\textit{ASTM}\)—\(\textit{Standard} E 606{-}12\).

- 2.

Using the same specimen could produce results invalidated by the material training by the previous cycles. The best practice is the use of a new specimen for each test.

- 3.

A difficulty could occur in the identification of the stabilized hysteresis loop. Often, depending on the material and strain level, dynamic stability is not reached, i.e. stress amplitude corresponding to an imposed strain amplitude tends to vary continuously during the test and, in some cases, until the rupture of the specimen. In this case a conventional definition of stabilized cycle is given, as the hysteresis cycle that corresponds to the mid-life of the specimen, i.e. to the half number of cycles to failure.

- 4.

In the case of components with states of non-proportional biaxial or triaxial stress (with loads agents not in phase with each other), in order to establish some reasonable estimation of the component strength, the reference specimen for analyzing the cyclic properties of the material must be arranged in such a way as to reproduce the same phase relationships that occur in reality [2, 19].

- 5.

Reversals number (equal to the double number of cycles) distinguishes the semi-cycle with positive strains from the semi-cycle with negative strains and it is more suitable to describe the load history.

- 6.

The concept of equivalence is related to an equivalent damage produced by the sequence of the hysteresis loops generated by real and by the virtual loads.

- 7.

Properly only if the load cycles are followed in descending order.

- 8.

Strain gages provided for large deformations have a very limited fatigue resistance and cannot be used for long load sequences.

- 9.

- 10.

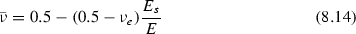

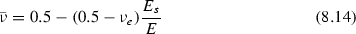

In order to overcome this difficulty a variable expression of \( \nu \) is introduced that must be determined by the cyclic stress-strain curve [35, 36]:

where:

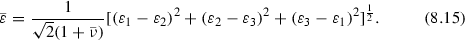

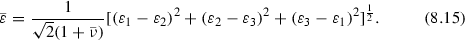

$$ {\left\{ \begin{array}{ll} {\buildrel \_ \over \nu } &{}= \text {variable Poisson coefficient} \\ E &{}= \text {elasticity modulus} \\ E_s &{}= \text {secant modulus on the cyclic curve} \\ \nu _e &{}= \text {Poisson's coefficient in the elastic field} \end{array}\right. } $$Secant modulus \(E_s\) is obtained from the cyclic curve utilizing the effective strain \({\buildrel \_ \over \varepsilon }\):

$$\gamma _{\textit{oct}} = {2 \over 3} \; \sqrt{2} \; (1 + {\buildrel \_ \over \nu }) \cdot {\buildrel \_ \over \varepsilon }$$that for Eq. 8.11 gives:

References

Curioni S, Freddi A (1989) Energy based torsional fatigue analysis. In: Kussmaul (ed) 3rd international conference on multiaxialfatigue, vol 1. MPA, Universitaet of Stuttgart (MPA)

Haibach E (2003) FKM-guideline: analytical strength assessment of components in mechanical engineering, 5th edn. VDMA, Frankfurt

Halford GR, Morrow J (1962) Low cycle fatigue in torsion. In: ASTM proceedings, ASME, vol 62, pp 695–707

Miller J (1971) Low cycle fatigue under biaxial strain controlled conditions. J Mater ASTM 7(3):307–314

Socie DF (1977) Fatigue-life prediction using local stress-strain concepts. Exp Mech 17(2):50–56

Curioni S, Freddi A (1990) Life prediction analysis with local strain approach. ÖIAZ Zeitschrift des Österreichische Ingenieuren und Architekten 1(7/8)

Bergmann J, Seeger T (1977) Über neuere verfahren der Anrisslebensdauervorhersage fur schwingbelastete Bauteile auf der Grundlage ortlicher Beanspruchengen. Z Werkstofftech 8-89-100 1, Verlag Chemie GmbH D, 6940 Weinheim

Olmi G, Freddi A (2010) Fatica oligociclica su cappe e rotori di turboalternatori, Quaderni del DIN, vol 1, 1st edn. Società Editrice Esculapio, Via U. Terracini 30 40131 Bologna (Italy), pp 117–142. http://amsacta.unibo.it/2771/

Wetzel RM (1977) Fatigue under complex loading. SAE Vol. AE-6, Warrendale, PA, USA

Imam MA, Chu HP, Rath BB (2002) Fatigue properties of titanium alloy Ti-6Al-2Cb-1Ta-0.8Mo. Mater Sci Eng A 323(1–2):457–461

Miwa Y, Jitsukawa S, Hishinuma A (1998) Development of a miniaturized hour-glass shaped fatigue specimen. J Nucl Mater 258–263:457–461

Sandhya R, Veeramani A, Bhanu Sankara Rao K, Mannan SL (1994) On specimen geometry effects in strain-controlled lowcycle fatigue. Int J Fatigue 16(3):202–208

Hirose T, Tanigawa H, Ando M, Kohyama A, Katoh Y, Narui M (2002) Radiation effects on low cycle fatigue properties of reduced activation ferritic/martensitic steels. J Nucl Mater 307–311

Kanchanomai C, Miyashita Y, Mutoh Y (2002) Low cycle fatigue behavior and mechanisms of a eutectic Sn-Pb solder 63Sn-37Pb. Int J Fatigue 24:671–683

Kanchanomai C, Miyashita Y, Mutoh Y (2002) Strain-rate effects on low cycle fatigue mechanism of eutectic Sn-Pb solder. Int J Fatigue 24:987–993

Kanchanomai C, Yamamoto S, Miyashita Y, Mutoh Y, McEvily AJ (2002) Low cycle fatigue test for solders using non-contact digital image measurement system. Int J Fatigue 24:57–67

Kanchanomai C, Miyashita Y, Mutoh Y, Mannan SL (2003) Influence of frequency on low cycle fatigue behavior of Pb-free solder 96.5Sn-3.5Ag. Mater Sci Eng A 345:90–98

Olmi G (2012) A novel method for strain controlled tests. Exp Mech 52(4):379–393

Garud YS (1981) A new approach to the evaluation of fatigue under multiaxial loadings. Trans ASME, J Eng Mater Technol 103:118–125

Stephens RI, Fatemi A, Stephens RR, Fuchs HO (2002) Metal fatigue in engineering, 2nd edn. Wiley, New York

Smith KN, Watson P, Topper TH (1970) A stress-strain function for the fatigue of metals. J Mater (JMLSA) 5(4):767–778

Matsuishi M, Endo T (1968) Fatigue of metals subjected to varying stress. Presentation report 1, Japan Society of of mechanical engineers, Fukuoka J

Palmgren AG (1924) Die Lebensdaur von Kugellagern (life length of roller bearings). Zeitschrift des Vereines Deutscher Ingenieure (VDI Zeitschrift) 68(14):339–341

Hoffmann K (1989) An introduction to measurements using strain gauges, vol 1, 1st edn. HBM GmbH, Darmstadt

Olmi G (2014) An experimental investigation on a crack propagating from a geartrain housing in an asphalt milling machine. Eng Failure Anal 38:38–48

McDiarmid DL (1991) A general criterion for high cycle multiaxial fatigue failure. Fatigue Fract Eng Mater Struct 14(4):429–453

Socie DF, Marquis GB (1999) Multiaxial Fatigue. Society of Automotive Engineers Inc. (SAE), Troy, Michigan. ISBN: 978-0768004533

Fleeter S, Zhou C, Houstis EN, Rice JR (1999) Fatigue life prediction of turbomachine blading

Rao J (2000) Turbine blade life estimation. Alpha Science Int’l Ltd, Oxford

Hutchinson JW (1968) Singular behaviour at the end of a tensile crack in a hardening material. J Mech Phys Solids 16:13–31

Mendelson A (1968) Plasticity: theory and applications, vol 1. Macmillan Company, New York

Nadai A (1950) Theory of flow and fracture of solids. McGraw Hill, New York

Yokobori Y (1968) An interdisciplinary approach to fracture and strength of solids, vol 1. Nordhoff W, Groningen, The Netherlands

Kikukawa M, Ohij K, Kotani S, Yokoi T (1972) A comparison of the axial and reverse—torsional strain cycling low-cycle fatigue strength of several structural materials. Bull J ASME 15(86):898–899

Gonyea DC (1973) Method for low-cycle fatigue design including biaxial stress and notch effects. ASTM STP 520:678–687

Stowell EZ (1956) Poisson’s ratio and volume changes for plastically orthotropic material. NACA TN (3736)

Tanaka K, Matsuoka S, Kouzu F, Nagata K (1983) Fatigue strength of a rotor steel subjected to torsional loading simulating that occurring due to circuit breaker reclosing in an electric power plant. Fatigue Eng Mater Struct 6(2):103–120

Beste A, Friedl KH, Mayer KH, Wiemann W (1982) Ermittlung der betriebsfestigkeit von turbogeneratorenwellen infolge electrischer storfalle. VGB Kraftwerkstechnike 62

Dowling NE (1978) Stress strain analysis of cyclic plastic bending and torsion. J Eng Mater Technol Trans ASME 100:294–302

Curioni S, Freddi A, Caligiana G, Gallano G (1983) Fatigue life prediction for shafts under torsional loading. In: Le May I and Monteiro SN (eds) Proceeding international congress fracture prevention in energy and transport systems, COBEM Brasilian congress on mechanical engineering, Rio de Janeiro, vol 1, pp 1–3. EMAS

Curioni S, Freddi A, Caligiana G (1990) Experimental techniques in torsional fatigue testing. In: SEM (ed) SEM spring conference on experimental mechanics experimental mechanics, society for experimental mechanics, Inc., vol 1. Bethel, Albuquerque NM (USA), see also http://www.sem.org/

Freddi A, Curioni S, Caligiana G (1989) La vita a fatica torsionale negli alberi dei turbo gruppi. La collaborazione ENEA industria nel settore termo-elettromeccanico, other collaborators: Dal Re V, Cammarota GP, Cesari F, Maggiore A, Medri GL, Nicoletto G, Persiani F, Veschi D

ASTM E606/E606M–12 (2012) Standard test method for strain-controlled fatigue testing. ASTM International, West Conshohocken, PA, USA

ISO 12106:2003 (2003) Metallic materials—fatigue testing—axial-strain-controlled method. International Organization for Standardization (ISO), Geneva, Switzerland

ISO 12107:2012 (2012) Metallic materials—fatigue testing—statistical planning and analysis of data. International Organization for Standardization (ISO), Geneva, Switzerland

EN ISO 6892-1:2009 (2009) Metallic materials—tensile testing. Part 1: Method of test at room temperature (ISO 6892-1:2009)

Hähner P, Rinaldi C, Bicego V et al (2008) Research and development into a European code-of-practice for strain-controlled thermo-mechanical fatigue testing. Int J Fatigue 30:372–381

Roessle ML, Fatemi A (2000) Strain-controlled fatigue properties of steels and some simple approximations. Int J Fatigue 22:495–511

Kandil FA, Dyson BF (1993) The influence of load misalignment during uniaxial low-cycle fatigue testing-I: modelling. Fatigue Fract Eng, Mater Struct 16(5):509–527

Kandil FA, Dyson BF (1993) The influence of load misalignment during uniaxial low-cycle fatigue testing-II: applications. Fatigue Fract Eng, Mater Struct 16(5):529–537

Thomas GB, Varma RK (1992) Evaluation of low cycle fatigue test data in the BCR/VAMAS intercomparison programme. In: Loveday M, Gibbons T (eds) Harmonisation of testing practice for high temperature materials. Elsevier Science Publisher, Oxford, pp 155–185

Pahl G, Beitz W (1997) Engineering design, a systematic approach. Springer, Berlin

Olmi G (2011) A new loading-constraining device for mechanical testing with misalignment auto-compensation. Exp Tech 35(6):61–70

Blomquist RS (1995) The design of a benign fail-safe mechanism using a low-melting-point metal alloy coupler. Appears in collection JPL TRS 1992, National Aeronautics and Space Administration (NASA), Houston, TX, United States. http://hdl.handle.net/2014/33266

Christ BW (1973) Effects of misalignment on the pre-macroyield region of the uniaxial stress-strain curve. Metall Trans 4(8):1961–1965

O’Kane RJ (1971) Discussion in elevated temperature testing problem areas. Am Soc Test Mater, STP 488:61–64

Penny RK, Ellison EG, Webster GA (1966) Specimen alignment and strain measurement in axial creep tests. Mater Res Stand 6(2):76–84

Birkbeck G, Petch NJ, Rae DM (1972) Eccentricity of loading in tensile testing. J Iron Steel Inst 210(9):675–679

UNI 6761–1992 (1992) Assembly tools. Minimum free space for tightening

Schmieder AK, Henry AT (1971) Axiality measurements on fifty creep machines. Am Soc Test Mater, STP 488:43–60

Atzori B, Meneghetti G, Ricotta M (2014) Unified material parameters based on full compatibility for low-cycle fatigue characterisation of as-cast and austempered ductile irons. Int J Fatigue 68:111–122

Olmi G (2012) An efficient method for the determination of the probability of failure on the basis of LCF data: application to turbogenerator design. SDHM Struct Durab Health Monit 8(1):61–89

Olmi G (2012) Low cycle fatigue experiments on turbogenerator steels and a new method for defining confidence bands. J Test Eval (JTE) 40(4):539–552

Olmi G, Freddi A (2014) Reliability assessment of a turbogenerator coil retaining ring based on low cycle fatigue data. Arch Mech Eng 61(1):5–34

Pang JHL, Xiong BS, Low TH (2004) Low cycle fatigue study of Lead free 99.3Sn-0.7Cu solder alloy. Int J Fatigue 26:865–872

Petersen C, Schmitt R, Gamier D (1996) Thermal and isothermal low cycle fatigue of manet i and ii. J Nucl Mater 233–237:285–288

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Freddi, A., Olmi, G., Cristofolini, L. (2015). Local Strain Models for Variable Loads. In: Experimental Stress Analysis for Materials and Structures. Springer Series in Solid and Structural Mechanics, vol 4. Springer, Cham. https://doi.org/10.1007/978-3-319-06086-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-06086-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-06085-9

Online ISBN: 978-3-319-06086-6

eBook Packages: EngineeringEngineering (R0)