Abstract

Since the day of its inception at Motorola Inc., Six Sigma methodology has been widely used in process improvement by companies all over the world including financial institutions. Users of Six Sigma strive to achieve competitiveness through improving processes. In recent years, “Lean” principles have been merged with the Six Sigma approach in what is known widely as Lean Six Sigma. Six Sigma is not only applicable to manufacturing but also to the service sector. With growing competition in the financial services sector, Six Sigma principles can be used to cut costs, increase efficiency and thereby help companies to stay afloat in the global economy. This paper will try to outline how Lean Six Sigma principles can be used to continuously improve service operations with special emphasis on financial institutions such as banks, insurance companies, individual pension systems, brokerage firms and others. A demonstrative case is also provided on how the principles can be applied in the context of a pension company.

Similar content being viewed by others

Keywords

1 Introduction

In today’s era of globalization, many financial institutions, especially banks, are facing a growing wave of competition from all over the world. Turkey is no exception to this global trend. According to the Turkish Union of Banks (TBB 2013a) there are 45 banks in Turkey as members of the union. Among these only 3 are public banks, 12 are private banks (including the major players such as Yapı Kredi, İş Bankası, Garanti Bankası and Akbank), 10 are foreign operated banks (such as Citibank, Denizbank), 6 are foreign banks with just branch operations (such as JP Morgan, Bank Mellat), 1 consolidated bank belonging to savings deposit insurance authority of the Turkish government (TMSF), and the remaining 13 are development and investment banks of which also 4 are foreign. With increasing involvement from global players it becomes important for the members of the banking sector to remain competitive. Table 11.1 provides the most recent figures on the number of branches operated by the most prominent banks in Turkey (TBB 2013b). These banks constitute 90 % of the total number of branches in Turkey.

There have been many useful innovations in the financial services sector since the 1960s. It used to be at some point that checks and cash deposits were the main operations of a bank. Credit cards changed the face of banking with the ability to pay with a plastic card. Even then, the card needed to be physically swiped and checked against a book of blacklisted card numbers. IT technologies further changed the face of banking with the ability to communicate online with the main servers. In a study drawing on detailed case studies of IT-based innovations, the five most important innovations have been identified as Interbranch Online service, Automated Teller Machine service, Credit Card service, Remote Banking service, and Electronic Funds Transfer service (Uchupalanan 2000). Today credit cards can even make use of chips with additional security and the ability to make offline touch free payments. Internet and smart phone applications also help the consumers conduct their transactions with ease.

Some innovations in the financial services sector can be in the form of completely radical products yet others can be in the form of improving existing services or processes. An improvement project may involve reducing the time it takes for the loan application and approval process. Another improvement project may involve designing a completely new loan application system such as one involving the use of SMS technology. In order to have a system for continuously improving existing services or processes companies can make use of quality management frameworks such as Six Sigma. The tools can differ in service or manufacturing contexts.

1.1 Service versus Manufacturing Operations

While many of the principles of quality management and operations management were originally developed in the context of manufacturing operations, nowadays service operations are equally important in terms of the application of efficiency improving techniques. In manufacturing operations a physical transformation generally takes place, whereas in service operations information flows may be more important. Starting with the early applications of Scientific Management techniques exemplified by Taylor’s work, the focus was on finding more efficient ways to perform various physical tasks (Taylor 1911). The case studies presented by Taylor included, for example, a shoveling experiment in which the shovel size that permitted the largest amount of coal to be physically shoveled per unit time was determined. The same principles may be applied in service settings, yet it is important to see how service and manufacturing operations are different in a number of different contexts:

-

1.

Products are generally tangible with the ability to keep inventories or return merchandise. A yearly auto insurance plan is not physical in nature (even the policy may be e-mailed); it cannot be returned, and will be valid until the end of the year, only then the customer may choose to switch to another provider.

-

2.

Product flows in a manufacturing process are more apparent, in a service delivery process document flows and information flows may be more important. A credit approval in a bank may require various physical documents such as pay stubs, photocopy of ID card; also it may require a credit history check over an online connection.

-

3.

Services are heterogeneous while products are more homogeneous. An individual pension plan may contain many different combinations of funds, monthly payments may change and even the age of the beneficiary plays a role in the event of termination.

-

4.

Services are simultaneously produced and consumed. A pension plan details may be determined as the sales process is going on. During the sales presentation it is inevitable that the service be customized according to the consumer’s needs (Esin 2004).

1.2 Improving Processes and New Process Design

The history of quality management has benefited vastly from the works of quality “gurus”. Especially one of the most prominent of these gurus, W. Edwards Deming, has stated 14 principles that guide the managers of leading companies. Among Deming’s 14 points, one of the most important point is “Point 5” where it is stated that companies should “improve constantly and forever the system of production and service to improve quality and productivity, and thus constantly decrease costs” (Deming 1982).

The Deming cycle, also known as the plan-do-study-act (PDSA) (or PDCA) cycle can aid managers in improving a process (Gitlow et al. 2005). All other frameworks used in different quality management programs are actually extensions of the PDSA cycle (such as DMAIC-Define, Measure, Analyze, Improve and Control—in Six Sigma terminology). The four stages in the Deming cycle start with “plan” stage where the analysts develop a plan to further improve a best-practice method developed before (maybe in the last cycle of improvement) and documented. This process could be a loan application system for a bank. The analyst would start with the flowchart of the existing process and try to come up with an improved flow chart. The “do” step involves conducting experiments on the alternative methods. The “study” stage analyzes the data collected in the previous stage. In the final “act” stage the managers chose an alternative and document the process to be used until the next process improvement cycle begins.

Frequently the design of products or services might restrict the dimensions in which they could be improved. As a solution the continuous improvement could start from the design of a product or service. Design for Six Sigma (DFSS for short) is a systematic methodology for designing new products (services), redesigning existing products (services) to exceed customer requirements. The DMAIC approach in Six Sigma is replaced by the DMADV method in DFSS (Brue & Howes 2006):

-

Define: Determine the goals and requirements of the customers (both internal and external)

-

Measure: Assess customer needs and specifications

-

Analyze: Examine the process options to meet the expectations of the customers

-

Design: Develop the process to meet the requirements

-

Verify: Check the design to make sure it meets the customer requirements

There are also some other acronyms used in conjunction with DFSS:

-

IDOV-Identify, Design, Optimize and Verify

-

DMADOV-Design, Measure, Analyze, Design, Optimize and Verify

-

DMCDOV-Define, Measure, Characterize, Design, Optimize and Verify

-

DCOV-Define Characterize, Optimize and Verify

-

DCCDI-Define, Customer, Concept, Design and Implement

-

DMEDI-Define, Measure, Explore, Develop and Implement

-

DMADIC-Define, Measure, Analyze, Design, Implement and Control

-

RCI-Define and Develop Requirements, Define and Develop Concepts, Define and Develop Improvements

This paper will continue and explain the fundamental frameworks of Lean Thinking, Six Sigma and the marriage of these frameworks in the form of Lean Six Sigma. We will also present a demonstrative application on an individual pension system to illustrate the application of Lean Six Sigma in an innovative design of a process related to acquisition of customers. The case is purely hypothetical.

2 Principles of Lean Thinking

Lean manufacturing, lean production, lean principles, lean enterprise or simply “lean” thinking derive their names from a focus on reducing waste and minimizing costs thereby improving efficiency in producing goods or services. The term actually started originally with Toyota Production System (TPS); however, the term “lean” came into popular use with the publication of a book called “The Machine That Changed the World” (Womack 1990; Holweg 2007).

Lean actually encompasses a set of tools and techniques that could be used to reduce waste. The seven types of waste (referred to as “Muda” in Japanese) are (Womack and Jones 2003):

-

1.

Transport

-

2.

Inventory

-

3.

Motion

-

4.

Waiting

-

5.

Overproduction

-

6.

Over processing

-

7.

Defects

After the application of lean tools, a number of cost reducing elements are realized. Lead times are shortened and thus revenue can grow dramatically. There is less handling and thus there will be less demand for people and equipment. There will be reduced space requirements and hence less rental costs. Due to the reduction in defects there will be less customer complaints (George 2002).

Many of the lean tools were provided in a book written by Shigeo Shingo about the Toyota Production System (Shingo 1989). In summary these tools can be categorized under the following headings:

-

Line Balancing: Balancing the flow of materials will eliminate the need to store the E-Type inventory which is mainly due to unbalanced flow between processes.

-

Single Minute Exchange of Dies (SMED): The setup times on machines will be unproductive downtime. SMED seeks to minimize this downtime resulting in speedy changeovers. This also reduces C-Type inventory accumulations or cushion stocks.

-

5S: In Japanese the words Seiri, Seiton, Seiso, Seiketsu, Shitsuke which are translated as Sorting, Setting in order, Systematic cleaning, Standardizing, and Sustaining. These “S” words prompt an organization to keep the workplace clean and orderly so that the inefficiencies are reduced. A worker delayed because he is unable to find a tool or a forklift not being able to navigate through the shop floor due to an obstacle are such examples of inefficiencies.

-

Pull systems: Production in the current workstation is prompted by the next workstation, hence there is no over production.

-

Reduced lot size: Batch sizes increase the level of inventories so an ideal lot size of one should be used.

-

Critical Path Analysis: Analyzing the flows, interdependent steps and operation times to coordinate the operations and reduce throughput time.

It might be thought that most of the items listed above including the seven Muda and some of the Lean tools are mostly manufacturing related. However the equivalents of the Lean concepts in terms of service applications also exist (Bicheno and Holweg 2009):

-

Delay: Customers waiting for services, examples may be for delivery such as packages, in queues as in a bank, for response as in a call center. The delays may result in lost customers or legal penalties.

-

Duplication: having to re-enter data, repeat details on forms, and answer queries from several sources within the same organization. An example may be callers repeating his/her account number and having to answer a secret question (such as mother’s maiden name) in multiple stages in calling a bank’s call center.

-

Unnecessary Movement: queuing several times, lack of one-stop, poor ergonomics in the service encounter. An automotive inspection facility may require documentation about tax and insurance status of the cars which require going to offices located in different buildings.

-

Unclear communication: waste of time spent in seeking clarification, confusion over product or service use, wasting time finding a location. Banks may use the help of navigation tools on cell phones to guide their customers to the branches or ATM locations.

-

Incorrect inventory: being out-of-stock, unable to get exactly what was required, substitute products or services. An example may be an automotive service shop not being able to fix a car because inventories of light bulbs for the headlights do not exist in the inventory.

-

Unfriendly Service Staff: an opportunity lost to retain or win customers, a failure to establish rapport, ignoring customers, unfriendliness, and rudeness. An unfriendly call center employee may cause the customer to switch to another company.

-

Defects: errors in the service transaction, product defects in the product-service bundle, lost or damaged goods. An example may be a stock broker giving the order for an incorrect stock purchase or incorrect amount.

3 Six Sigma and Lean Thinking

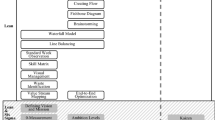

A popular application of the waste reduction principles and short term focus of “Lean” techniques with the continuous improvement and methodologically advanced foundations of “Six Sigma” culminated in the formation of a set of principles often termed as “Lean Six Sigma”. Lean Six Sigma can be described as an approach focused on improving quality, reducing variation and eliminating waste in an organization (Furterer 2009). The marriage of Lean and Six Sigma could be explained in a number of broad headings (de Koning et al. 2008):

-

Organization: Six sigma approach provides the organization with a solid framework of roles and responsibilities under names such as Green Belts (GBs), Black Belts (BBs), Master Black Belts, project Champions and etc. The organization structure in Lean Six Sigma is directly derived from Six Sigma.

-

Methodology: The DMAIC approach from Six Sigma is used as given in Table 11.2. In the case of design of new products the DMADV approach can be used replacing the Improve and Control phases with Design and Verify phases.

Table 11.2 DMAIC approach of lean six sigma (de Koning et al. 2008) -

Tools and techniques: Some tools from Lean are used in stages of DMAIC. For example value stream mapping (a technique that involves analyzing the flow of goods and information in a service or manufacturing environment) can be used in Analyze 1 stage.

-

Concepts and classifications: Both approaches supply their own jargon. Six Sigma CTQ (Critical to Quality Characteristic) can be used from Lean concepts such as tact time (cycle time), critical path and waste can be used.

Overall “Lean Six Sigma” can be defined as a methodology that strives to maximize shareholder value by achieving a fast rate of improvement in speed, customer satisfaction and quality while also minimizing cost and invested capital. The reason why the two approaches were fused into one was mainly due to the fact that Lean approaches alone do not take advantage of statistical tools and techniques present in Six Sigma and that Six Sigma alone does not pay enough attention to increasing process speed and reduce capital investments (George 2002). It is also true that when employees make intellectual contributions to the improvements through using the DMAIC improvement cycle, there will be a more positive work environment and decreased levels of stress (Gitlow 2009).

4 A Demonstrative Application on a Pension Company

Voluntary contribution based retirement systems have been in existence in many parts of the developed world and constitute an important percentage of the funds in the global financial system. The 401 K system in the US is one such example. Turkey for a long time relied solely on the State Pension system. On October 07, 2001 the law number, 4,632 on Individual Pension Savings and Investment System came into force. It was passed by the parliament of Turkey on March 28 and published in the official gazette on April 7. This law was meant to provide a system which would be complementary to the already existing state social security system. In the beginning, the contributions to the new system would be tax deductible; currently there is a new incentive that would provide a certain percentage of state contributions in addition to the individual’s contributions. The new system would work on the basis of voluntary participation by depositing a predefined quantity monthly to the pension company account maintained for the beneficiary individual. The main motivation of the law was to direct individual pension savings to investment and to improve the welfare level of the individual by providing a supplementary income during retirement period. The additional savings would also contribute to the economic development of Turkey by creating long term resources for the economy. After the law and some other legislation were passed, Turkish Individual Pension System practically started operations on October 27, 2003 with the founding of six pension companies. Currently there exist 17 pension companies in the Turkish system (EGM 2013).

In any individual pension company there are a number of different operations, among these are:

-

Making initial contact with customers: Potential customers may be approached by sales agents who have the necessary certificates. In some cases affiliated banks may be used to create contacts either in the branches or by online banking tools.

-

Maintaining databases of current and potential customers: Potential customers can be taken from affiliated banks’ databases or personnel records of companies. Current and terminated customers’ lists should also be kept for CRM purposes.

-

Assessment of risk profile of the customer: Various questionnaires can be used to assess what kind of funds the customer is most likely to invest in. This step can be skipped by some companies.

-

Opening an account: The account opening requires a formal application with national ID present. The initial entrance fee needs to be charged and the customer needs to select a pension plan and the monthly payment quantity.

-

Changing between pension plans: Customers may wish to switch between plans, such as switching from a plan investing in treasury bonds to one investing in stocks.

-

Switching funds to another company: Transfer of funds to any company is possible within certain limitations. This would involve written application from the beneficiary, where the beneficiary states which company the funds are to be transferred to.

-

Taking over funds from another company: Similar to the previous action, except this time the company is receiving a new customer from another company.

-

Consolidating different accounts opened within the company: In some cases the same person may have more than one account in the same company and may wish to consolidate those.

-

Sending routine statements to the customers: This transaction may be online depending on the wishes of the customer or in some cases paper statements may need to be sent every month showing the contributions, deductions, and the current state of the funds.

-

Sending routine statements to the pension monitoring board: Since the pension monitoring board oversees the state contributions it needs to have a consolidated picture of all the accounts owned by one individual. Also pension company activities need to be monitored.

-

Financial operations: Allocating group funds to different sources such as government securities, stocks, foreign currency and etc.

-

Termination and exit from the system: Calculation of total amount to be paid to the beneficiary, informing the pension board and transfer of funds to the consumer.

-

Seizure of funds: Some customers’ funds may be seized due to bankruptcy or debt.

It is evident that the processes listed above are prone in many ways to different kinds of waste and can be the subject of improvement projects. The processes involve many different flows of physical documents and information. The organization of the flows of information and physical documents might result in different ways of getting the services performed with maximal customer satisfaction and minimum costs. Most of the above stated processes are repeated on a regular basis, most of the time monthly while some will take place once in the life of the customer (such as exit from the system). Having even minor improvements in efficiency of a process repeated monthly could dramatically reduce the costs and thereby increase profits of the pension company. In a highly regulated industry such as the pension system Lean Six Sigma may come as a useful tool for managers. In the remainder of this section we will go through the DMAIC steps and show how Lean Six Sigma could be applied in the context of streamlining the application, risk profile building and new account opening operations of an individual pension company. The tools are kept as general as possible so the readers can get a clear view of the application of the steps in a wide variety of financial services contexts.

4.1 Overview of the Pension Sales Transaction

Pension companies can perform sales through a multitude of channels. The sales agents, regardless of which channel they take part in, must have a certification in individual pension sales. One of the most important channels is the use of an affiliated bank. Many pension companies have an affiliated bank as another member of the larger corporation they are part of. Both banks and pension companies find this arrangement very useful as the banks earn commission income and the pension companies could use the infrastructure, information database of the banks and client circulation of bank branches in generating sales. There are a number of different commission structures in pension sales.

There could be a one-time commission given to the agent (which is the case with many independent agents) or otherwise the commission could be spread out to the lifecycle of the pension. The former system may not be advantageous since the pension beneficiary is free to transfer to other companies with certain restrictions. Generally, in the affiliated bank sales channel the commissions are spread out to the lifecycle and the bank and pension company sign an agreement that will ensure the proper distribution of the commissions between the bank and the pension company. Overall using the bank as a sales channel provides many advantages. In a popular application, the bank branches can be visited by the licensed financial advisors working for the pension company with a certain frequency. During the one or two week long stay of the advisor, the branch visitors would be approached with the intention to generate pension contracts. The transaction could optionally include a risk profile assessment and would end with entering the personal data into the pension company system and signing the necessary paperwork. There are a number of areas that could be prone to improvement in such a transaction.

4.2 Define Phase

The main aim of this first phase is to depict the specific business problem at hand and outline the scope of the project and the process to be improved. In general the following five steps need to be completed in this phase:

-

1.

Development of the project charter

-

2.

Identification of customers and stakeholders: SIPOC analysis (Pyzdek 2003) is a useful tool in the Define Phase and it aims at identifying the interrelationships between the Suppliers, Inputs, Processes, Outputs and Customers.

-

3.

Definition of critical to satisfaction (CTS) and voice of customer criteria: Defects, delivery times, processing costs can all be elements of CTS.

-

4.

Formation of the project team and determination of responsibilities

-

5.

Creation of the project plan

The aim of the project for the pension company is to improve the efficiency of the operations involved with creating new plans at the bank branches. The stakeholders are the customers, bank branch employees, Pension Company, government agencies and the affiliated bank. The CTS could include the time it takes to convince and sign customers (this may include data entry requirements, examining documentation etc.). Another CTS would be the retention rate of the customer within the next year (if the customer leaves before the first year no commission would be gained).

4.3 Measure Phase

The main aim of this second phase is to understand and document the existing state of the process to be improved. In general the following five steps need to be completed in this phase:

-

1.

Definition of the current process: Flowcharts about the current system.

-

2.

Definition of the VOC (voice of customer): Satisfaction of the customer from the transaction, time it takes to complete the transaction.

-

3.

Definition of the VOP (voice of process) and current status of the performance measures: Data entry, documentation, back office operation times.

-

4.

Validation of the measurement system: Setting operational definitions for how the VOC and VOP will be measured. As an example the customer satisfaction from the transaction can be measured by a survey placed on the online banking system to be administered next time the customer logs on.

-

5.

Definition of COPQ (cost of poor quality): All training costs, customers lost to other pension companies, IT costs, labor hours spent for communication, document handling, mistaken data entry etc.

4.4 Analyze Phase

In this step the data collected in the measure phase are analyzed through the plethora of quality management and control tools. Developing cause and effect relationships, statistical tools and process capability analyses could be performed. As a contribution of “Lean” thinking to the “Six Sigma” approach waste analysis is conducted at this stage. Non-value adding activities like printing multiple copies of the documents, scanning or photocopying some documents, calling the pension company center for approvals, manually entering data and many other sources of waste can be analyzed. Lean tools here supplement statistical tools such as correlation analysis, histograms, Pareto analyses and regression analysis.

A “Cause and effect matrix” can be constructed, showing the relative magnitude of the effects of the various causes on the CTS criteria. This results in a relative weighting with decreasing order of importance for the causes on the CTS criteria. 5S analysis, another Lean tool, helps to organize the workplace. The elements of 5S are sorting, setting in order, systematically cleaning, standardizing, and sustaining (simplifying, straightening, scrubbing, stabilizing and sustaining is another version of the translation of the 5S).

4.5 Improve Phase

The main aim of this penultimate phase is to identify the recommendations, run pilot projects and document the improvements. In general the following six steps need to be completed in this phase, with examples from the pension company:

-

1.

Identification of the improvement recommendations: Data entry phase could be improved by IT integration with the bank database, risk profile assessment could be completed with the ATM machines or through the online services of the bank, signature and document processing could be moved to the back office personnel of the bank.

-

2.

Cost benefit analyses: IT integration costs, extra load to the back office personnel.

-

3.

Designing the proposed state: Flow charts and necessary amendments to the ATM and online banking tools.

-

4.

Establishment of performance targets: Percentage increase in the efficiency of the financial advisors, retention rates of the customers in the first year, and customer satisfaction rates.

-

5.

Gaining approval to implement: Approval of both the bank and pension company management.

-

6.

Training and execution: Training the financial advisors of the pension company and the back office personnel of the bank branches for the proposed state.

4.6 Control Phase

During the control phase, the results from pilot projects are evaluated and the replication opportunities in other parts of the organization are examined. This stage generally includes the following five steps:

-

1.

Measurement of the results from pilot implementation projects

-

2.

Reporting the results: Reductions in time required to complete the financial transactions, one financial advisor would be able to sign on 50 % more customers during a typical stay in a branch. Customer retention during the first year may be improved.

-

3.

Replication opportunities: Can the same methods be applied elsewhere in the pension company. This may reduce costs further.

-

4.

Future plans: Lessons learned and the next possibility for improvement.

5 Conclusion

Operations managers and service operations managers have been trying to achieve efficiency and productivity increases since the initial days of industrialization. Currently, the focus is more on service operations more than ever with the intense competition in the services sector. Financial services are also the spotlight in terms of improvements in efficiency and productivity.

A very important branch of financial services in the developing and developed economies is the Individual Pension System. This highly regulated industry is crucial for the economic stability of a country and the well-being of its citizens. Close to its 10th year of operations, the system in Turkey is getting close to a total of 3.5 million customers and total assets in excess of 20 billion TL. Turkey has come a long way in a short period of time in terms of the percentage of GDP invested in pension funds and percentage of population covered by private pension plans, yet there is still more to accomplish in terms of reaching the corresponding levels of the developed countries.

Just like all financial services providers, managers of individual pension companies need to manage multiple distribution channels, innovate products, streamline daily operations, and invest in marketing strategies aimed at acquiring new customers and keeping existing ones. Lean Six Sigma tools can help individual pension companies further cut operational costs and increase efficiency thereby ultimately helping the consumers improve their savings habit even more. Lean Six Sigma tools can also be applied in insurance companies to reduce claims processing times, in finance departments of companies or government offices to reduce monthly reporting cycle times, and in banks to reduce credit application cycle times.

In this article we have tried to outline the use of Lean Six Sigma principles which can help managers in financial institutions in terms of remaining competitive against their global rivals. In the ever changing global economic circumstances, distribution channels and financial instruments must be continuously innovated and improved in order to stay competitive. Lean Six Sigma can promise to deliver these incremental improvements.

References

Bicheno, J., & Holweg, M. (2009). The lean toolbox: The essential guide to lean transformation. Buckingham: Picsie Books.

Brue, G., & Howes, R. (2006). The McGraw-Hill 36-hour course in Six Sigma. New York: McGraw-Hill.

De Koning, H., Does, J. M. M., & Bisgaard, S. (2008). Lean Six Sigma in financial services. International Journal of Six Sigma and Competitive Advantage, 4(1), 1–17.

Deming, W. E. (1982). Quality, Productivity and Competitive Position. Cambridge: MIT Press.

EGM (2013). Information about the individual pension system of Turkey obtained from Pension Monitoring Center of Turkey (Emeklilik Gözetim Merkezi-EGM). http://www.egm.org.tr/?pid=358. Accessed 04 Feb 2013.

Esin, A. (2004). ISO 9001:2000 Işığında Hizmette Toplam Kalite. Ankara: ODTU Press.

Furterer, S. L. (2009). Lean Six Sigma in service: applications and case studies. Boca Raton: CRC Press.

George, M. L. (2002). Lean Six Sigma: Combining Six Sigma quality with lean speed. New York: McGraw-Hill.

Gitlow, H. S. (2009). A guide to lean Six Sigma management skills. Boca Raton: CRC Press.

Gitlow, H. S., Oppenheim, A. J., Oppenheim, R., & Levine, D. M. (2005). Quality management. New York: McGraw-Hill.

Holweg, M. (2007). The genealogy of lean production. Journal of Operations Management, 25, 420–437.

Pyzdek, T. (2003). A complete guide for green belts, black belts, and managers at all levels. New York: McGraw-Hill.

Shingo, S. (1989). A study of the Toyota production system: From an industrial engineering point of view. New York: Productivity Press.

Taylor, F. W. (1911). The principles of scientific management. New York: Harper and Row.

TBB (2013a). Information on member banks of Turkish Union of Banks as of 23.01.2013. http://www.tbb.org.tr/modules/banka-bilgileri/banka_Listesi.asp?tarih=23.01.2013. Accessed 23 Jan 2013.

TBB (2013b). Information on number of branches of Turkish Union of Banks members as of 23.0.2013. http://www.tbb.org.tr/modules/banka-bilgileri/banka_sube_bilgileri.asp?tarih=23.01.2013. Accessed 23 Jan 2013.

Uchupalanan, K. (2000). Competition and it-based innovation in banking services. International Journal of Innovation Management, 04, 455–460.

Womack, J. P., & Jones, D. T. (2003). Lean thinking. NY: Free Press.

Womack, J. P., Jones, D. T., & Roos, D. (1990). The machine that changed the world: The story of lean Production. New York: Rawson Associates.

Acknowledgments

I would like to thank the Society for the Study of Business and Finance, the editors and chapter editors of the “Globalization of Financial Institutions” volume and the anonymous reviewers for the valuable feedback they provided during the preparation of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Editor information

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Akkucuk, U. (2014). Application of Lean Six Sigma Methodology in Design and Improvement of Financial Services. In: Dincer, H., Hacioglu, Ü. (eds) Globalization of Financial Institutions. Springer, Cham. https://doi.org/10.1007/978-3-319-01125-7_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-01125-7_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-01124-0

Online ISBN: 978-3-319-01125-7

eBook Packages: Business and EconomicsEconomics and Finance (R0)