Abstract

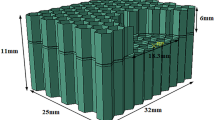

The article considers solving the problem of precision cutting of honeycomb blocks. The urgency of using arbitrary shapes application cutting from honeycomb blocks made of modern composite materials is substantiated. The problem is to obtain a cut of the given shape from honeycomb blocks. The complexity of this problem is in the irregular pattern of honeycomb blocks and the presence of double edges, which forces an operator to scan each block before cutting. It is necessary to take into account such restrictions as the place and angle of the cut and size of the knife, its angle when cutting and the geometry of cells. For this problem solving, a robotic complex has been developed. It includes a device for scanning the geometry of a honeycomb block, software for cutting automation and a cutting device itself. The software takes into account all restrictions on the choice of the location and angle of the operating mechanism. It helps to obtain the highest quality cut and a cut shape with the best strength characteristics. An actuating device has been developed and implemented for both scanning and cutting of honeycomb blocks directly. The necessary tests were carried out on real aluminum honeycomb blocks. Some technical solutions are used in the cutting device to improve the quality of cutting honeycomb blocks. The tests have shown the effectiveness of the proposed complex. Robotic planar cutting made it possible to obtain precise cutting with a high degree of repeatability.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bayraktar, E.: Section 12 composites materials and technologies (2016). https://doi.org/10.1016/b978-0-12-803581-8.04108-4

Crupi, V., Epasto, G., Guglielmino, E.: Comparison of aluminium sandwiches for lightweight ship structures: honeycomb vs. foam. Mar. Struct. 30, 74–96 (2013)

Jin, X., Li, G., Gao, S., Gong, J.: Optimal design and modeling of variable-density triangular honeycomb structures. In: 2017 8th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, pp. 138–143 (2017)

Crupi, V., Epasto, G., Guglielmino, E.: Collapse modes in aluminium honeycomb sandwich panels under bending and impact loading. Int. J. Impact Eng. 43, 6–15 (2012). https://doi.org/10.1016/j.ijimpeng.2011.12.002

Hu, Z., et al.: Design of ultra-lightweight and high-strength cellular structural composites inspired by biomimetics. Compos. B Eng. (2017). https://doi.org/10.1016/j.compositesb.2017.03.033

Yan, L., Xu, H., Deng, Y.: 3D digital mockup for honeycomb sandwich panels of satellites. In: 2018 IEEE 4th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, pp. 1956–1959 (2018)

Wenjian, J., Lanlan, Z., Feng, W., Jinwen, S., Yun, L.: Structural design and realization of a mechanical reconfigurable antenna. In: 2018 International Conference on Electronics Technology (ICET), Chengdu, pp. 349–353 (2018)

Regassa, Y., Lemu, H., Sirabizuh, B.: Trends of using polymer composite materials in additive manufacturing. In: IOP Conference Series: Materials Science and Engineering, vol. 659, p. 012021 (2019). https://doi.org/10.1088/1757-899x/659/1/012021

OpenCV Homepage. https://opencv.org. Accessed 30 July 2020

TensorFlow Homepage. https://www.tensorflow.org. Accessed 30 July 2020

Keras Homepage. https://keras.io. Accessed 30 July 2020

Acknowledgements

This work was supported by the Ministry of Science and Higher Education of the Russian Federation (State Contract No. FEFE-2020-0017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Kubrikov, M.V., Saramud, M.V., Karaseva, M.V. (2020). Problem of Robotic Precision Cutting of the Geometrically Complex Shape from an Irregular Honeycomb Grid. In: Chan, C.S., et al. Intelligent Robotics and Applications. ICIRA 2020. Lecture Notes in Computer Science(), vol 12595. Springer, Cham. https://doi.org/10.1007/978-3-030-66645-3_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-66645-3_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66644-6

Online ISBN: 978-3-030-66645-3

eBook Packages: Computer ScienceComputer Science (R0)