Abstract

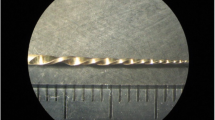

In order to avoid fractures of endodontic instruments within the root canal, rotary endodontic files have been manufactured in nickel titanium alloy, either conventional or with different thermal treatments. However, fatigue fractures continue to occur, preventing root canal cleaning and shaping. In our research we explored the possibility that titanium niobium alloy may be useful in the manufacture of endodontic rotary files due to its resistance to fatigue fracture. Simulations of the fatigue failure were made by means of finite elements in wires with the properties of the proposed alloys and they were validated experimentally finding similar results. Likewise, simulations of fatigue failure were made of models of the F2 file of Protaper series® with the same mechanical properties tested on the wires but only the rotary file composed of nickel titanium alloy was experimentally validated.

It was found that the niobium titanium alloy virtual file was more resistant to fatigue failure than the nickel titanium alloy file, therefore with the limitations of the present study, it can be concluded that titanium-niobium could be an alternative material for the manufacture of endodontic files.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Schilder, H.: Cleaning and shaping the root canal. Dent. Clin. North Am. 18(2), 269–296 (1974)

Seltzer, S., Soltanoff, W., Sinai, I., Goldenberg, A., Bender, I.B.: Biologic aspects of endodontics part III. periapical tissue reactions to root canal instrumentation. 1968. J. Endod. 30(7), 491–499 (2004). Discussion 489–490

Gallegos, A.G., Bertolotti, R.L.: Effect of sodium hypochlorite on the strength of carbon steel endodontic instruments. J. Endod. 7(9), 423–425 (1981)

Craig, R.G., Mc Ilwain, E.D., Peyton, F.A.: Comparison of theoretical and experimental bending and torsional moments of endodontic files and reamers. J. Dent. Res. 46(5), 1058–1063 (1967)

Darabara, M., Bourithis, L., Zinelis, S., Papadimitriou, G.D.: Assessment of elemental composition, microstructure, and hardness of stainless steel endodontic files and reamers. J. Endod. 30(7), 523–526 (2004)

Walia, H.M., Brantley, W.A., Gerstein, H.: An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 14(7), 346–351 (1988)

Riggans Jr., J.W.: The case history of a root perforation and a method for its prevention. Dent. Digest 77(5), 275–279 (1971)

Chernick, L.B., Jacobs, J.J., Lautenschlager, E.P., Heuer, M.A.: Torsional failure of endodontic files. J. Endod. 2(4), 94–97 (1976)

Camps, J.J., Pertot, W.J.: Relationship between file size and stiffness of stainless steel instruments. Endod. Dent. Traumatol. 10(6), 260–263 (1994)

Bahcall, J.K., Carp, S., Miner, M., Skidmore, L.: The causes, prevention, and clinical management of broken endodontic rotary files. Dent. Today 24(11), 74, 76, 78–80, quiz 80 (2005)

Fu, M., Zhang, Z., Hou, B.: Removal of broken files from root canals by using ultrasonic techniques combined with dental microscope: a retrospective analysis of treatment outcome. J. Endod. 37(5), 619–622 (2011)

Sattapan, B., Nervo, G.J., Palamara, J.E., Messer, H.H.: Defects in rotary nickel-titanium files after clinical use. J. Endod. 26(3), 161–165 (2000)

Kaval, M.E., Capar, I.D., Ertas, H.: Evaluation of the cyclic fatigue and torsional resistance of novel nickel-titanium rotary files with various alloy properties. J. Endod. 42(12), 1840–1843 (2016)

Kaval, M.E., Capar, I.D., Ertas, H., Sen, B.H.: Comparative evaluation of cyclic fatigue resistance of four different nickel-titanium rotary files with different cross-sectional designs and alloy properties. Clin. Oral Invest. 21(5), 1527–1530 (2017)

Montalvao, D., Shengwen, Q., Freitas, M.: A study on the influence of Ni-Ti M-Wire in the flexural fatigue life of endodontic rotary files by using Finite Element Analysis. Mater. Sci. Eng. C Mater. Biol. Appl. 40, 172–179 (2014)

Rodrigues, C.T., Duarte, M.A., de Almeida, M.M., de Andrade, F.B., Bernardineli, N.: Efficacy of CM-Wire, M-Wire, and nickel-titanium instruments for removing filling material from curved root canals: a micro-computed tomography study. J. Endod. 42(11), 1651–1655 (2016)

Miyazaki, S., Kim, H.Y.: 2 - basic characteristics of titanium–nickel (Ti–Ni)-based and titanium–niobium (Ti–Nb)-based alloys. In: Miyazaki, S., Kim, H.Y. (eds.) Shape Memory and Superelastic Alloys, pp. 15–42. Woodhead Publishing (2011)

Saito, T., Furuta, T., Hwang, J.H., Kuramoto, S., Nishino, K., Suzuki, N., et al.: Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism. Science 300(5618), 464–467 (2003)

Rodrigues, R.C., Lopes, H.P., Elias, C.N., Amaral, G., Vieira, V.T., De Martin, A.S.: Influence of different manufacturing methods on the cyclic fatigue of rotary nickel-titanium endodontic instruments. J. Endod. 37(11), 1553–1557 (2011)

Nino-Barrera, J.L., Aguilera-Canon, M.C., Cortes-Rodriguez, C.J.: Theoretical evaluation of Nickel-Titanium Mtwo series rotary files. Acta Odontol. Latinoam.: AOL 26(2), 90–96 (2013)

Cheung, G.S., Zhang, E.W., Zheng, Y.F.: A numerical method for predicting the bending fatigue life of NiTi and stainless steel root canal instruments. Int. Endod. J. 44(4), 357–361 (2011)

Braga, L.C., Faria Silva, A.C., Buono, V.T., de Azevedo Bahia, M.G.: Impact of heat treatments on the fatigue resistance of different rotary nickel-titanium instruments. J. Endod. 40(9), 1494–1497 (2014)

Acosta, E.C., Resende, P.D., Peixoto, I.F., Pereira, E.S., Buono, V.T., Bahia, M.G.: Influence of cyclic flexural deformation on the torsional resistance of controlled memory and conventional nickel-titanium instruments. J. Endod. 43(4), 613–618 (2017)

Murakami, T., Iijima, M., Muguruma, T., Yano, F., Kawashima, I., Mizoguchi, I.: High-cycle fatigue behavior of beta-titanium orthodontic wires. Dent. Mater. J. 34(2), 189–195 (2015)

Sekar, V., Kumar, R., Nandini, S., Ballal, S., Velmurugan, N.: Assessment of the role of cross section on fatigue resistance of rotary files when used in reciprocation. Eur. J. Dent. 10(4), 541–545 (2016)

Pruett, J.P., Clement, D.J., Carnes Jr., D.L.: Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 23(2), 77–85 (1997)

Figueiredo, A.M., Modenesi, P., Buono, V.: Low-cycle fatigue life of superelastic NiTi wires. Int. J. Fatigue 31(4), 751–758 (2009)

Lee, M.H., Versluis, A., Kim, B.M., Lee, C.J., Hur, B., Kim, H.C.: Correlation between experimental cyclic fatigue resistance and numerical stress analysis for nickel-titanium rotary files. J. Endod. 37(8), 1152–1157 (2011)

Chapala, P., Acharyya, S.G., Shariff, S.M., Naik, G.: Novel Ti-Nb alloys with improved wear resistance for biomedical implant application. Conference proceedings. In: Annual International Conference of the IEEE Engineering in Medicine and Biology Society IEEE Engineering in Medicine and Biology Society Annual Conference 2016, pp. 4208–4211 (2016)

Niinomi, M.: Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti-29Nb-13Ta-4.6Zr. Biomaterials 24(16), 2673–2683 (2003)

Baek, S.H., Lee, C.J., Versluis, A., Kim, B.M., Lee, W., Kim, H.C.: Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 37(9), 1283–1286 (2011)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Nino-Barrera, J., Rodriguez-Montano, O., Cortes-Rodriguez, C. (2020). Evaluation of Titanium-Niobium Alloy as a Possible Material to Manufacture Endodontic Files. In: González Díaz, C., et al. VIII Latin American Conference on Biomedical Engineering and XLII National Conference on Biomedical Engineering. CLAIB 2019. IFMBE Proceedings, vol 75. Springer, Cham. https://doi.org/10.1007/978-3-030-30648-9_83

Download citation

DOI: https://doi.org/10.1007/978-3-030-30648-9_83

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-30647-2

Online ISBN: 978-3-030-30648-9

eBook Packages: EngineeringEngineering (R0)