Abstract

Glucose is not only as a main metabolic material, but also as a signaling molecule during the process of plant growth. In this work, for the first time, we developed an electrochemical microbiosensor suitable for real-time detecting of glucose concentration in plants. The biosensor uses glucose oxidase (GOD) to catalyze the glucose, and uses cellulose acetate (CA) and polycarbonate (PC) to improve the electrochemical selectivity and reduce the dependence of response on ambient oxygen. The linear range of the proposed sensor is wide and the detection limit is lower, which could basically meet the needs of plant testing. The content of glucose in sunflower under salt stress was monitored in real-time successfully, confirming the applicability of the fabricated microbiosensor. This work has a potential to open an innovative way to study the dynamic changes of physiological state of the plants in real-time.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Recently, researchers have found that sugar is an important regulator for the growth and gene expression of plants. For plants, sugar not only is the energy source and structural substance, but also has a hormone-like primary messenger function in signal transduction [1,2,3,4,5]. For instance, soluble sugar, including glucose, trehalose, sucrose and so on, will be accumulated in the plant cells under the drought stress. These soluble sugars are involved in osmoregulation and may play a role for protein stability in plants. Therefore, it is important to carry out quantitative analysis for sugars in plants.

The conventional methods for the determination of soluble sugar in plants includes liquid chromatography [6], gas-chromatography [7], near infrared spectroscopy [8], and fluorescence [9], etc. However, great damage could be caused by these methods to the plant for collecting the plant tissue samples. And the results obtained by these methods always reflect the static concentration or the cumulative effect at a given time, and can’t reflect the real-time dynamic changes of the metabolic substances in the plant when the environment changes. In order to understand the physiological law of plants more comprehensively and guide agricultural production, people hope to acquire the real-time dynamic changes of these important sugars in plants. So, new methods should be developed for real-time monitoring of sugars in plants.

Electrochemical biosensors has the advantages of high sensitivity, good selectivity, portability, rapid response, and ease of automatization, etc. [10,11,12]. Specially, electrochemical microbiosensors are suitable for real-time detection in living bodies. Recently, electrochemical microbiosensors had made a substantial progress in the study of neurophysiology and neuropharmacology. Electrochemical microbiosensors have been applied for real-time detection of glucose [13,14,15,16,17], acetylcholine [18, 19], dopamine [20,21,22], ATP [23], cholesterol [24] and glutamate [25] in different animals. Some electrochemical microbiosensors also have been applied to monitor the H2O2 [26] or NO [27] in real-time in plants. However, to our best knowledge, no electrochemical microbiosensors have been developed for monitor sugars in real-time in plants.

Glucose is a major soluble sugar. Here, for the first time, we developed a needle-type electrochemical microbiosensor which can be used for real-time detecting of glucose in plants. The biosensor uses glucose oxidase (GOD) to catalyze the glucose reaction, and uses cellulose acetate (CA) and polycarbonate (PC) to improve the electrochemical selectivity and reduce the dependence of response on ambient oxygen. The glucose microbiosensor shows good sensitivity and selectivity. The content of glucose in sunflower under salt stress was also monitored successfully using the developed microbiosensor in real-time.

2 Materials and Methods

2.1 Chemicals and Materials

Glucose, cellulose acetate (CA), glutaraldehyde (glutar), sucrose, lactose, glycine, sorbitol, maltose, Poly(bisphenol A carbonate) (PC), glucose oxidase (GOD), bovine serum albumin (BSA), raffinose, galactose, fructose were purchased from Sigma-Aldrich Co. LLC. (Shanghai, China). Phosphate buffered solution (0.01 M, pH 7.4) was purchased from Beijing Solarbio Science & Technology Co., Ltd. (Beijing, China). All other chemicals used were analytically grade and purchased from Beijing Chemical Works (Beijing, China). Ultrapure water was used through the whole experiments.

2.2 Fabrication of the PC/GOD/Glutar/CA/Pt Needle Electrode

Platinum (Pt) wire electrode was obtained from Tianjin Ida company which diameter is about 0.5 mm. Before using, Pt wire electrode was polished with 1.0–0.05 μm alumina slurry in turn, then sonicated 5 min in deionized water and ethanol, and rinsed thoroughly by deionized water and ethanol. Then electrode was placed in concentrated nitric acid for 10 min, followed by washing. Then it was subsequently voltammetrically cycled in 0.1 M sulfuric acid from 0 to +1.5 V at 0.1 V/s until the Pt wire electrode was clean.

The clean Pt wire electrode was modified primarily by immersing in acetone of 2% CA for 2 min, then dried in the air. Then the CA/Pt electrode was immersed in 2% glutaraldehyde solution for 2 h. After washing and drying again, the glutar/CA/Pt electrode was incubated in 10μL 10 mg/mL GOD/BSA (1:1) in PBS (pH 7.4, 0.01 M) for 20 h at 4 °C. Following rinsing and drying, the GOD/glutar/CA/Pt electrode was promptly soaked by 8% PC in dichloromethane for 2 min, and dried in the air. The PC in dichloromethane was prepared freshly before use due to the volatilization property of dichloromethane. Finally, the PC/GOD/glutar/CA/Pt electrode was rinsed with PBS, and dried in the air. The whole process for fabrication of the glucose sensor for plant is displayed in Scheme 1.

2.3 Preparation of Plant Samples

The sunflower seeds (LD5009) were gained from Inner Mongolia academy of agriculture and animal husbandry sciences. Firstly, the seeds were sterilized. Then they were planted into sandy soil in polyethylene containers and cultured in an illuminating incubator (10 h/14 h of light/dark period, 25 °C, 60% humidity). After sprouted, the evenly size seedlings were selected and transplanted into Hoagland solution [28]. After 15 days, the healthy seedlings were randomly divided into two groups. Then different concentrations of NaCl (0 and 200 mM) were introduced into the Hoagland solution for fabricating salt stress.

2.4 Electrochemical Measurements

Most of the electrochemical experiments were performed on an electrochemical working station (CHI 660C, CH Instruments, Shanghai, China) at room temperature. The real-time detecting of glucose in sunflowers under salt stress was performed on a multi-channel CHI 1000C instrument. A two-electrode system was used. The prepared Pt wire was employed as working electrode, the Ag/AgCl wire was employed as reference/counter electrode. Both the working and reference electrode were wrapped by leaving 2 mm for sensing length with insulating tape.

In situ determination of glucose in sunflowers were done by sticking the PC/GOD/glutar/CA/Pt electrode and Ag/AgCl electrode into the stem of the sunflowers about 2 mm depth without piercing through. For different plant, the electrodes were inserted into the same site as possible.

3 Result and Discussion

3.1 Characterization of the Glucose Sensor

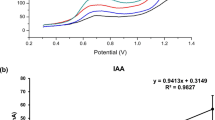

To characterize the electrochemical properties of the prepared glucose sensor, cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) were employed to detect each fabrication step of the proposed sensor. Figure 1(A) shows the CV curves for each fabrication step. The bare Pt needle electrode shows reversible redox behavior of the Fe(CN) 4−/3−6 (curve 1). After the CA coated onto the Pt needle electrode, the redox peak current decreased (curve 2), indicating that CA layer has coated on the electrode. After glutaraldehyde was absorbed on the CA coated electrode, the peak current decreased further (curve 3), because of the formed barrier from glutaraldehyde. After the GOD was immobilized on the glutar/CA/Pt electrode, the reversibility of the redox curve was lost markedly (curve4). This suggests that enzyme was cross-linked onto the CA membrane through glutaraldehyde successfully. No obvious redox peaks were observed in curve 5, indicating the PC layer has been formed on the electrode.

(A) Cyclic voltammograms for (1) bare Pt electrode, (2) CA/Pt electrode, (3) glutar/CA/Pt electrode, (4) GOD/glutar/CA/Pt electrode, (5) PC/GOD/glutar/CA/Pt electrode. (B) Nyquist plots of impedance spectras for (1) bare Pt electrode, (2) CA/Pt electrode, (3) glutar/CA/Pt electrode, (4) GOD/glutar/CA/Pt electrode, (5) PC/GOD/glutar/CA/Pt electrode. All the electrochemical works above here were scanned in 5 mM [Fe(CN) 6] 3−/4− in 0.01 M PBS (pH 7.4).

Figure 1(B) shows the characterization of EIS for the process of the fabrication. A simple equivalent circuit model (the inset in Fig. 1B) was used to match the impedance spectroscopy. After the CA membrane formed, the electron-transfer resistance significantly increased to 2.28 kΩ (curve 2) compared to the curve of bare Pt electrode (curve 1), as the CA layer interdicted the electron-transfer from the redox ions to the electrode surface. After the glutaraldehyde (curve 3) and the GOD (curve 4) cross-linked onto the CA membrane of the electrode surface, the Ret increased to 8.37 kΩ, due to the compact structure of the fabricated layers. After the PC layer formed on the electrode (curve 5), that corresponding Ret increased further, which ascribed to the steric hindrance effect of PC layer. The result of EIS also illustrated that the electrode had been modified successfully.

3.2 Optimization of Glucose Sensor Modified Conditions

As is known to all that most of the enzyme based glucose sensors detect the electrons produced from the hydrogen peroxide amperometric reaction [29, 30]:

According to the principle, the Eq. (1) is the key reaction of the determination. In this work, There are three layers were proposed to cover the electrode, the enzyme layer was in the middle protected by the layers of CA and PC coatings.

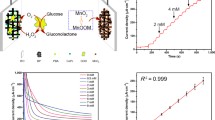

CA was used as diffusion restricting membrane to depress the diffusion rate of glucose molecules, so as to control the whole reaction process [31, 32]. The concentration of CA was optimized. The concentration of CA in acetone was changed from 1% to 5%, and the I-t response of glucose was measured using a series of concentrations of glucose (0, 5, 10, 50, 100, 200, 300 mM) in phosphate buffer. As shown in Fig. 3A, the highest currents response and good linearity in the whole measuring range can be achieved using the 2% CA, hence 2% is the optimal concentration for CA for this sensor.

The analytical performance of enzyme-based glucose sensor could be highly rely on the amount of enzyme applied [29, 30], so a range concentrations of GOD (5, 10, 20, 30, 40, 50 mg/ml) was investigated. As shown in Fig. 2B, it can be observed that the highest concentration of GOD didn’t provide the best catalytic efficiency. Considering the current response and the linearity in the whole measuring range, the optimal concentration of GOD is 10 mg/ml.

The enzyme reaction need the involvement of oxygen [33,34,35], the PC coating can limit the reactive amount of glucose to reduce the influence of oxygen content [36], and also resist the interference of other biomolecules. So, the concentration of PC was also optimized. The applied concentration of PC was 2%, 5%, 8%, 10%. As shown in Fig. 2C, it could be seen that the currents response and linearity was best at the PC concentration of 8%, which was chosen to be used for the real-time measurement of glucose.

3.3 Performance of Glucose Sensor

The multi-layer modified glucose sensor was used to detect the different concentrations of glucose applied at 0.6 V. After the stabilization of current of the modified electrode in PBS, the current response of a series of concentrations of glucose solution was recorded. Each concentration of glucose was measured 15 min to obtain a relatively stable current curve. Figure 3 shows the plot of current response versus glucose concentration. The applied concentration of glucose was from 5 to 300 mM, which covers the glucose concentration range in most plants. With the increase of glucose concentration, the current response is also increased. The inset of Fig. 3 exhibits a linear with logarithm of glucose concentration ranging from 5 mM to 300 mM. The calibration equation is ΔI(μA) = 0.607LN[cglucose(mM)] − 0.968, and the calibration coefficient is 0.987. We were able to detect 0.1 mM glucose directly, indicating a detection limit of 0.1 mM for glucose.

Other soluble sugars in plants, such as raffinose, galactose, sucrose, etc., may interfere the detection of glucose. So the amperometric responses of possibly existed interferences on the glucose sensor was studied. As demonstrated in Fig. 4, each substance was tested 120 s. The proposed glucose sensor did not show distinct response to the interferences while maintaining high sensitivity to glucose. This result indicated that the proposed sensor has good selectivity.

3.4 In Vivo Measurements of Glucose Levels in the Stem of Sunflowers Under Salt Stress

Sugar is a main product of photosynthesis. It is not only as a metabolic material, but also as a signal molecule for the regulation for the plant growth. In this work, to avoid the effect of photosynthesis, the real-time measurement of glucose in sunflower was carried out at night. The two groups of sunflowers under different salt stress (0 mM and 200 mM NaCl) were measured at the same time by using a multi-channel CHI1000C instrument. As shown in Fig. 5b, there might be a self-stabilization stage for the sensor during the initial part of the measurement. However, distinct difference has been observed for the glucose levels of the two groups of sunflowers at the initial stage of the measurement. From 1000 s to 5000 s, it was found that the glucose level of sunflowers under 200 mM NaCl treatment is higher than the control group. Researchers have found that the salt stress have a reverse effect on the growth of plants, so this increase of glucose level may be due to a decrease in the utilization of glucose in growth [37, 38]. Stems of plants usually carry the function of transporting nutrients, this increase of glucose level may also be due to some changes in their translocation through the plant. However, after that, the glucose levels of the two groups tended to be consistent. This result may be due to that the accumulated glucose has been consumed because of the lack of photosynthesis. Santos also reported that the levels of soluble sugars of the sunflower cells will be increased under salt and osmotic stress, but the contribution of the soluble sugars to the osmotic potential was low [38]. Our results confirmed their conclusions to some extent. The glucose microbiosensor developed here was able to sense the change of glucose in the stem of sunflowers in real-time successfully.

(A) Image for in situ detection of glucose in the stem of sunflower seedling by the glucose sensor, the electrodes were connected to the working electrode wire (1), reference electrode wire (2), counter electrode wire (3) separately. (B) I-t responses obtained by the glucose sensor in situ in the stem of sunflower seedlings under salt stress at night. Two concentrations of NaCl (0, 200 mM) were used.

4 Conclusion

In this work, we developed a needle type glucose microbiosensor which can be used for measurement of glucose levels in plants in real-time. The sensor showed a broad linear range and a lower detection limit, which can basically meet the needs of plant testing. This is the first real-time measurement of glucose in plants, which gives us information about the dynamic changes of its physiological state under stresses. This study has a potential to open an innovative way to study of the dynamic changes of physiological state of the plants in real-time.

References

Rioukhamlichi, C., Menges, M., Healy, J.M.S., Murray, J.A.H.: Sugar control of the plant cell cycle: differential regulation of Arabidopsis D-type cyclin gene expression. Mol. Cell. Biol. 20, 4513–4521 (2000)

Mishra, B., Singh, M., Aggrawal, P., Laxmi, A.: Glucose and auxin signaling interaction in controlling Arabidopsis thaliana seedlings root growth and development. PLoS ONE 4, e4502 (2009)

Takeda, H., Sugahara, T., Kotake, T., Nakagawa, N., Sakurai, N.: Sugar treatment inhibits IAA-induced expression of endo-1,3:1,4-beta-glucanase EI transcripts in barley coleoptile segments. Physiol. Plant. 139, 413–420 (2010)

Kircher, S., Schopfer, P.: Photosynthetic sucrose acts as cotyledon-derived long-distance signal to control root growth during early seedling development in Arabidopsis. PNAS 109, 11217–11221 (2012)

Cho, Y.-H., Hong, J.-W., Kim, E.-C., Yoo, S.-D.: Regulatory functions of SnRK1 in stress-responsive gene expression and in plant growth and development. Plant Physiol. 158, 1955–1964 (2012)

Han, J.H., Choi, H.N., Park, S., Chung, T.D., Lee, W.Y.: Mesoporous platinum electrodes for amperometric determination of sugars with anion exchange chromatography. Anal. Sci. 26, 995–1000 (2010)

Wahjudi, P.N., Patterson, M.E., Shu, L., Yee, J.K., Mao, C.S., Lee, W.P.: Measurement of glucose and fructose in clinical samples using gas chromatography/mass spectrometry. Clin. Biochem. 43, 198–207 (2010)

Xie, L.J., Ye, X.Q., Liu, D.H., Ying, Y.B.: Quantification of glucose, fructose and sucrose in bayberry juice by NIR and PLS. Food Chem. 114, 1135–1140 (2009)

Tan, W., Zhang, D., Wang, Z., Liu, C., Zhu, D.: 4-(N, N-Dimethylamine) benzonitrile (DMABN) derivatives with boronic acid and boronate groups: new fluorescent sensors for saccharides and fluoride ion. J. Mater. Chem. 17, 1964–1968 (2007)

Guo, Y., et al.: Label-free detection of T4 DNA ligase and polynucleotide kinase activity based on toehold-mediated strand displacement and split G-quadruplex probes. Sens. Actuators B: Chem. 214, 50–55 (2015)

Fan, J., Qi, K., Zhang, L., Zhang, H., Yu, S., Cui, X.: Engineering the Pt/Pd interfacial electronic structures for highly-efficient hydrogen evolution and alcohol oxidation. ACS Appl. Mater. Interfaces. 9, 18008–18014 (2017)

Sun, J., Wang, B., Zhao, X., Li, Z.-J., Yang, X.: Fluorescent and colorimetric dual-readout assay for inorganic pyrophosphatase with Cu2+-triggered oxidation of o-phenylenediamine. Anal. Chem. 88, 1355–1361 (2016)

Zhang, F.F., et al.: Simultaneous monitoring of glucose, lactate, L-glutamate and hypoxanthine levels in rat striatum by a flow-injection enzyme electrode array system with in vivo microdialysis sampling. J. Electroanal. Chem. 575, 1–7 (2005)

Kohma, T., Oyamatsu, D., Kuwabata, S.: Preparation of selective micro glucose sensor without permselective membrane by electrochemical deposition of ruthenium and glucose oxidase. Electrochem. Commun. 9, 1012–1016 (2007)

Ward, W.K., Jansen, L.B., Anderson, E., Reach, G., Klein, J.C., Wilson, G.S.: A new amperometric glucose microsensor: in vitro and short-term in vivo evaluation. Biosens. Bioelectron. 17, 181–189 (2002)

Rocchitta, G., et al.: Simultaneous telemetric monitoring of brain glucose and lactate and motion in freely moving rats. Anal. Chem. 85, 10282–10288 (2013)

Koh, A., Lu, Y., Schoenfisch, M.H.: Fabrication of nitric oxide-releasing porous polyurethane membranes coated needle-type implantable glucose biosensors. Anal. Chem. 85, 10488–10494 (2013)

Schuvailo, O.N., et al.: Carbon fibre-based microbiosensors for in vivo measurements of acetylcholine and choline. Biosens. Bioelectron. 21, 87–94 (2005)

Mitchell, K.M.: Acetylcholine and choline amperometric enzyme sensors characterized in vitro and in vivo. Anal. Chem. 76, 1098–1106 (2004)

Phillips, P.E., Wightman, R.M.: Extrasynaptic dopamine and phasic neuronal activity. Nat. Neurosci. 7, 199 (2004). Author reply 199

Phillips, P.E.M., Stuber, G.D., Heien, M.L.A.V., Wightman, R.M., Carelli, R.M.: Subsecond dopamine release promotes cocaine seeking. Nature 422, 614–617 (2003)

Rice, M.E., Cragg, S.J.: Nicotine amplifies reward-related dopamine signals in striatum. Nat. Neurosci. 7, 583–584 (2004)

Dale, N., Pearson, T., Frenguelli, B.G.: Direct measurement of adenosine release during hypoxia in the CA1 region of the rat hippocampal slice. J. Physiol. 526, 143–155 (2000)

Yoneyama, Y., et al.: Wireless biosensor system for real-time cholesterol monitoring in fish “Nile tilapia”. Talanta 80, 909–915 (2009)

Rahman, M.A., Kwon, N.H., Won, M.S., Choe, E.S., Shim, Y.B.: Functionalized conducting polymer as an enzyme-immobilizing substrate: an amperometric glutamate microbiosensor for in vivo measurements. Anal. Chem. 77, 4854–4860 (2005)

Zou, Q.J., et al.: In vivo measurements of changes in pH triggered by oxalic acid in leaf tissue of transgenic oilseed rape. Phytochem. Anal. 18, 341–346 (2010)

Wen, W., et al.: A highly sensitive nitric oxide biosensor based on hemoglobin–chitosan/graphene–hexadecyltrimethylammonium bromide nanomatrix. Sens. Actuat. B 166–167, 444–450 (2012)

Hoagland, D.R., Arnon, D.I.: Growing plants without soil by the water-culture method. Circ. Calif. Agric. Exp. Stn. (1938)

Gough, D.A., Lucisano, J.Y., Tse, P.H.: Two-dimensional enzyme electrode sensor for glucose. Anal. Chem. 57, 2351–2357 (1985)

Gough, D.A., Kumosa, L.S., Routh, T.L., Lin, J.T., Lucisano, J.Y.: Function of an implanted tissue glucose sensor for more than one year in animals. Sci. Transl. Med. 2, 42 (2010)

Tinkilic, N., Cubuk, O., Isildak, I.: Glucose and urea biosensors based on all solid-state PVC–NH 2 membrane electrodes. Anal. Chim. Acta 452, 29–34 (2002)

Jdanova, A.S., Poyard, S., Soldatkin, A.P., Jaffrezic-Renault, N., Martelet, C.: Conductometric urea sensor. Use of additional membranes for the improvement of its analytical characteristics. Anal. Chim. Acta 321, 35–40 (1996)

Wang, J.: In vivo glucose monitoring: towards ‘sense and act’ feedback-loop individualized medical systems. Talanta 75, 636–641 (2008)

Wilson, G.S., Gifford, R.: Biosensors for real-time in vivo measurements. Biosens. Bioelectron. 20, 2388 (2005)

Wilkins, E., Atanasov, P., Muggenburg, B.A.: Integrated implantable device for long-term glucose monitoring. Biosens. Bioelectron. 10, 485–494 (1995). Biosensors 1994 - 2.52

Tatsuma, T., Okawa, Y., Watanabe, T.: Enzyme monolayer- and bilayer-modified tin oxide electrodes for the determination of hydrogen peroxide and glucose. Anal. Chem. 61, 2352–2355 (1989)

Roussos, P.A., et al.: Intra- and inter-cultivar impacts of salinity stress on leaf photosynthetic performance, carbohydrates and nutrient content of nine indigenous Greek olive cultivars. Acta Physiol. Plant. 39, 136 (2017)

dos Santos, C.L.V., Caldeira, G.: Comparative responses of helianthus annuus plants and calli exposed to NaCl: I. Growth rate and osmotic regulation in intact plants and calli. J. Plant Physiol. 155, 769–777 (1999)

Acknowledgements

The authors are thankful for the funds from the National Natural Science Foundation of China (Grant No. 61571443), Scientific and Technological Innovation Team of Beijing Academy of Agricultural and Forestry Sciences (JNKYT201604).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 IFIP International Federation for Information Processing

About this paper

Cite this paper

Hu, Y., Wang, C., Li, A. (2019). An Amperometric Glucose Microbiosensor for Real-Time Measurements in Plants. In: Li, D., Zhao, C. (eds) Computer and Computing Technologies in Agriculture XI. CCTA 2017. IFIP Advances in Information and Communication Technology, vol 545. Springer, Cham. https://doi.org/10.1007/978-3-030-06137-1_44

Download citation

DOI: https://doi.org/10.1007/978-3-030-06137-1_44

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-06136-4

Online ISBN: 978-3-030-06137-1

eBook Packages: Computer ScienceComputer Science (R0)